Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Sweeper Brush Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

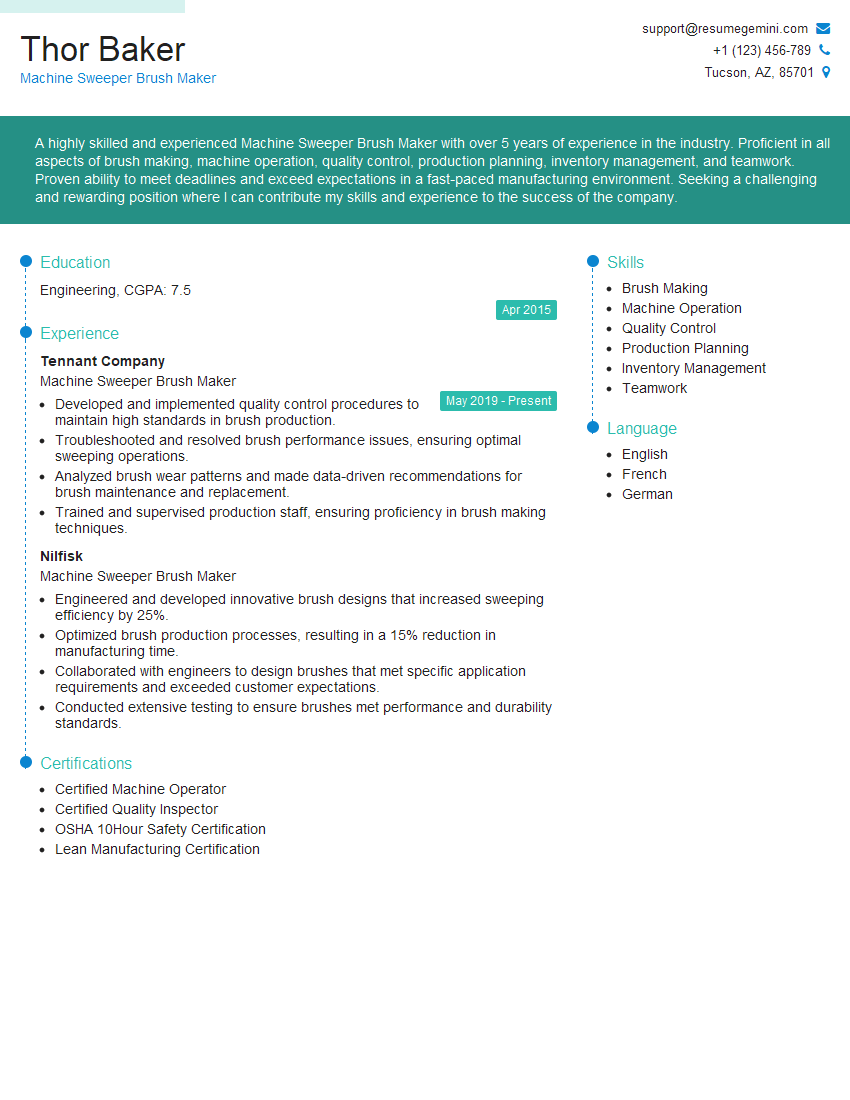

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Sweeper Brush Maker

1. What are the key considerations when selecting materials for machine sweeper brushes?

When selecting materials for machine sweeper brushes, I consider several key factors:

- Bristle Type: The type of bristles used can impact the effectiveness and durability of the brush. Nylon bristles are commonly used for their durability and resistance to wear, while polypropylene bristles offer flexibility and are suitable for scrubbing applications.

- Bristle Density: The density of the bristles affects the sweeping performance. A higher bristle density provides more contact points with the surface, resulting in enhanced sweeping efficiency.

- Block Material: The block that holds the bristles must be durable and resistant to impact and abrasion. Common materials used include polypropylene and rubber, offering a balance of strength and flexibility.

2. Explain the process of winding and trimming machine sweeper brush filaments.

Winding:

- Set up the winding machine with the appropriate filament material and winding pattern.

- Load the brush core onto the winding spindle and begin wrapping the filament around it.

- Maintain tension on the filament to ensure a tight and uniform wind.

Trimming:

- Once the winding process is complete, trim the excess filament at the ends of the brush.

- Use a sharp blade or scissors to create a clean and precise cut.

- Ensure the trimmed length is consistent across all bristles for optimal sweeping performance.

3. Describe the different types of machines used in the production of machine sweeper brushes.

- Winding Machines: These machines are used to wrap the filaments around the brush core to create the bristles.

- Trimming Machines: Used to trim the bristles to the desired length and ensure uniformity.

- Block Molding Machines: These machines shape and form the brush block that holds the bristles in place.

- Assembly Machines: Automate the process of inserting the bristles into the brush block and securing them.

- Testing Machines: Used to evaluate the quality and performance of the finished brushes.

4. Discuss the importance of quality control in machine sweeper brush manufacturing.

- Ensuring Performance: Proper quality control ensures that the brushes meet the required specifications and perform effectively in sweeping applications.

- Durability and Longevity: Regular inspection and testing help identify and address potential defects, enhancing the lifespan of the brushes.

- Customer Satisfaction: Delivering high-quality brushes leads to customer satisfaction and repeat business.

- Brand Reputation: Maintaining consistent quality standards builds a strong brand reputation and sets the company apart in the market.

5. Explain how you would optimize the efficiency of a machine sweeper brush production line.

- Streamline Production Flow: Analyze the production process and identify bottlenecks. Implement measures to improve material handling, optimize machine settings, and reduce downtime.

- Utilize Automation: Incorporate automated machines and systems to increase production speed and reduce labor costs.

- Preventive Maintenance: Regularly maintain and calibrate equipment to prevent breakdowns and ensure smooth operation.

- Optimize Workforce: Train operators to handle multiple tasks and promote teamwork to minimize production delays.

- Implement Lean Manufacturing Principles: Apply lean principles to eliminate waste, improve efficiency, and reduce production costs.

6. What are the potential safety hazards associated with machine sweeper brush manufacturing and how do you mitigate them?

- Rotating Machinery: Implement proper guarding and ensure regular maintenance to prevent injuries from contact with rotating parts.

- Filament Trimmings: Use dust collection systems and personal protective equipment to minimize exposure to airborne filament particles.

- Chemical Hazards: Handle and store chemicals used in the production process safely, following proper safety protocols.

- Ergonomic Risks: Design workstations to reduce repetitive motions and provide ergonomic support to prevent musculoskeletal disorders.

- Training and Awareness: Conduct regular safety training and ensure employees are informed about potential hazards and safe work practices.

7. Describe the process of troubleshooting a machine sweeper brush that is not sweeping effectively.

- Inspect the Bristles: Check for any damage, wear, or contamination that may affect sweeping performance.

- Examine the Brush Block: Ensure the bristles are securely attached to the block and there are no cracks or deformations.

- Test the Machine: Run the sweeper on a test surface to observe the sweeping action and identify any issues.

- Analyze the Results: Based on the observations, determine the root cause of the problem, such as worn bristles, misalignment, or insufficient brush pressure.

- Implement Solutions: Replace worn bristles, adjust the brush settings, or perform necessary repairs to restore the sweeper’s effectiveness.

8. How do you stay updated on the latest advancements in machine sweeper brush technology?

- Industry Exhibitions and Conferences: Attend trade shows and industry events to learn about new products and innovations.

- Technical Publications and Journals: Subscribe to industry-specific publications and journals to stay informed about research and development.

- Online Resources: Utilize online platforms, forums, and manufacturer websites to access technical articles, white papers, and product updates.

- Networking with Experts: Connect with professionals in the field, such as engineers, researchers, and suppliers, to exchange knowledge and insights.

- Continuing Education Courses: Participate in workshops, seminars, or online courses to expand my understanding of the latest technologies and best practices.

9. What strategies do you employ to ensure customer satisfaction with machine sweeper brushes?

- Meeting Customer Requirements: Understand and fulfill the specific needs and expectations of each customer.

- Providing High-Quality Products: Manufacture and supply brushes that meet or exceed industry standards for quality and performance.

- Responsive Customer Service: Address customer inquiries promptly and effectively, providing technical support and troubleshooting assistance.

- Gathering Feedback: Regularly collect customer feedback to identify areas for improvement and enhance product offerings.

- Building Relationships: Foster long-term relationships with customers through personalized service and open communication.

10. Discuss the future trends and developments in the machine sweeper brush industry.

- Advanced Materials: Exploration of new materials and technologies to enhance brush performance, durability, and efficiency.

- Automation and Robotics: Integration of automation and robotics in brush manufacturing to improve productivity and reduce labor costs.

- Data Analytics: Use of data analytics to optimize brush design, predict maintenance needs, and improve overall operations.

- Sustainability: Focus on developing environmentally friendly and sustainable brushes using recyclable materials and reducing waste.

- Customization: Increased demand for customized brushes tailored to specific applications and customer needs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Sweeper Brush Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Sweeper Brush Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Sweeper Brush Makers play a vital role in manufacturing and maintaining machine sweeper brushes used for industrial and commercial cleaning applications. Their key responsibilities include:

1. Brush Assembly and Fabrication

Assemble and fabricate machine sweeper brushes to meet specifications, ensuring proper size, shape, and bristle configuration.

- Select and cut bristles to precise lengths and diameters.

- Bind and secure bristles into brush blocks using adhesives, epoxy, or other fastening methods.

- Inspect and test brushes to ensure quality and functionality.

2. Material Handling and Inventory Management

Handle and manage raw materials, including bristles, brush blocks, and adhesives, to ensure continuous supply.

- Receive, store, and inventory materials.

- Maintain proper storage conditions to prevent damage and deterioration.

- Coordinate with suppliers for timely material delivery.

3. Machine Operation and Maintenance

Operate and maintain machinery used in brush making, including winding machines, cutting machines, and testing equipment.

- Set up and adjust machines for optimum operation.

- Troubleshoot and resolve equipment malfunctions.

- Perform regular maintenance to ensure smooth and efficient operation.

4. Quality Control and Inspection

Inspect and test finished brushes to ensure they meet quality standards and customer specifications.

- Measure brush dimensions, bristle density, and other parameters.

- Identify and rectify any defects or non-conformances.

- Maintain inspection and testing records for quality assurance.

Interview Tips

To prepare effectively for an interview as a Machine Sweeper Brush Maker, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and market position. Research the machine sweeper brush industry to understand its trends and key players.

2. Highlight Your Technical Skills

Emphasize your experience in brush assembly, material handling, machine operation, and quality control. Quantify your accomplishments whenever possible, using specific examples and metrics.

3. Prepare for Common Interview Questions

Review common interview questions and prepare thoughtful responses. Consider questions related to your technical skills, problem-solving abilities, and experience in the industry.

- Example: “Tell us about your experience in assembling and fabricating machine sweeper brushes.”

- Example: “Describe a situation where you encountered a technical issue and how you resolved it.”

4. Practice Your Presentation

Rehearse your answers to interview questions in front of a mirror or with a friend. This will help you build confidence and deliver your responses clearly and concisely.

5. Be Prepared to Ask Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare a few questions about the company’s culture, growth opportunities, or specific projects related to brush making.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Sweeper Brush Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!