Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Tailer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

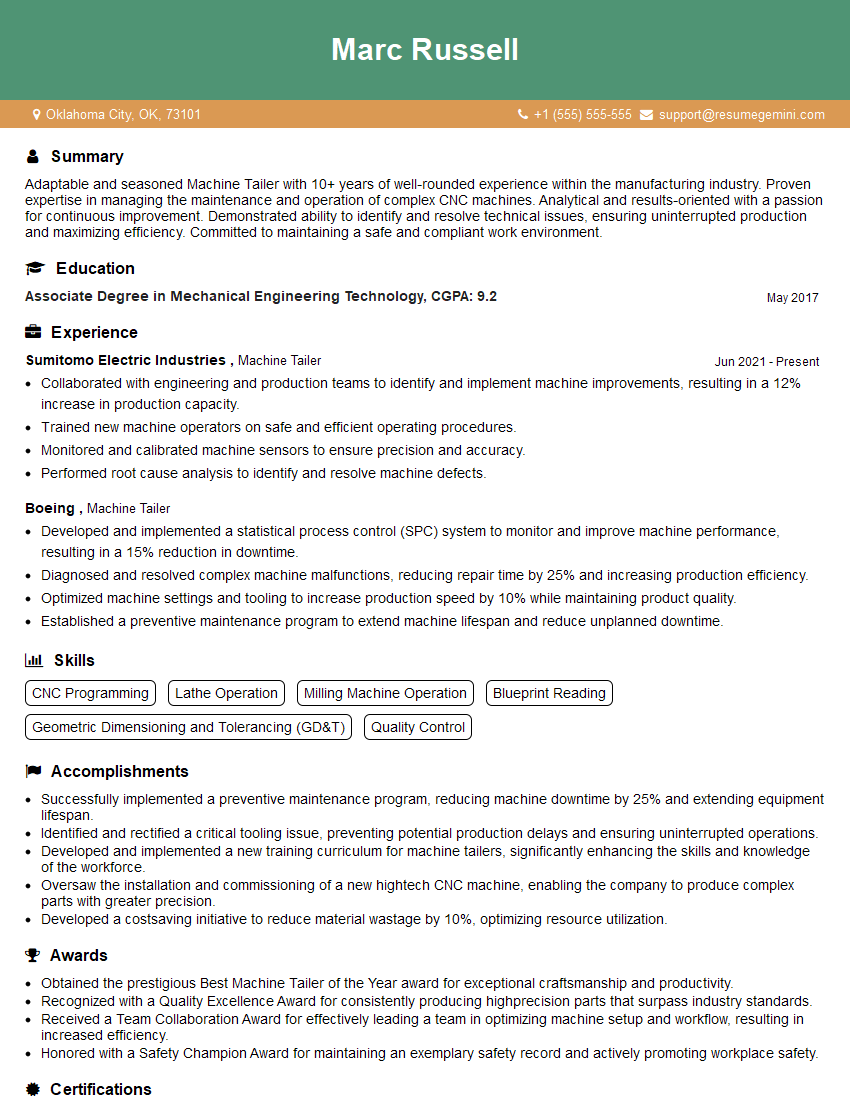

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Tailer

1. What are the different types of machine tools used in a machine shop?

- Computer Numerical Control (CNC) machines

- Manual machines

- Lathes

- Mills

- Grinders

- Sheet metal working machines

- Welding machines

2. What are the different types of materials that can be machined?

Metals

- Steel

- Aluminum

- Brass

- Copper

Plastics

- ABS

- Polyethylene

- Polypropylene

- Polyvinyl chloride (PVC)

Wood

- Hardwoods

- Softwoods

- Plywood

- Medium-density fiberboard (MDF)

3. What are the different types of machining operations that can be performed?

- Turning

- Milling

- Drilling

- Boring

- Reaming

- Tapping

- Grinding

- Polishing

4. What are the different types of cutting tools used in machining?

- Single-point cutting tools

- Multi-point cutting tools

- Drills

- Taps

- Dies

- Abrasives

5. What are the different types of machine tool controls used in a machine shop?

- Manual control

- Computer numerical control (CNC)

- Direct numerical control (DNC)

- Adaptive control

6. What are the different types of machine tool accessories used in a machine shop?

- Workholding devices

- Cutting tools

- Measuring tools

- Lubricants

- Coolants

7. What are the different types of safety precautions that must be taken when operating a machine tool?

- Wear appropriate safety gear

- Keep work area clean and free of debris

- Inspect machine tool before each use

- Follow all operating instructions

- Never leave a machine tool unattended while it is running

- Report any unsafe conditions or practices to your supervisor

8. What are the different types of maintenance procedures that must be performed on a machine tool?

- Daily maintenance

- Weekly maintenance

- Monthly maintenance

- Quarterly maintenance

- Annual maintenance

9. What are the different types of troubleshooting procedures that must be performed on a machine tool?

- Identify the problem

- Determine the cause of the problem

- Correct the problem

- Test the machine tool to verify that the problem has been corrected

10. What are the different types of quality control procedures that must be performed on a machine tool?

- Inspect the raw material

- Inspect the finished product

- Test the machine tool to verify that it is operating properly

- Calibrate the machine tool

- Maintain records of all quality control procedures

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Tailer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Tailer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Tailers, also known as Sewing Machine Operators, play a vital role in the garment industry. They are responsible for operating various types of sewing machines to create and assemble garments.

1. Machine Operation

- Setting up and operating various types of sewing machines, including straight stitch, overlock, and buttonhole machines

- Adjusting machine settings, including stitch length, tension, and feed rate, to ensure optimal performance

- Monitoring machines while operating and identifying any potential problems or malfunctions

2. Fabric Handling

- Loading, unloading, and handling a variety of fabrics, including woven, knitted, and leather

- Ensuring proper fabric handling techniques to prevent damage or distortion

- Inspecting fabrics for defects and identifying any inconsistencies

3. Garment Assembly

- Following production specifications to assemble garments according to design requirements

- Sewing seams, attaching buttons, zippers, and other components

- Inspecting garments for quality and accuracy before passing them on for finishing

4. Production Efficiency

- Meeting production targets by maintaining a consistent pace and accuracy

- Identifying and implementing methods to improve efficiency and reduce waste

- Working as part of a team to ensure smooth production flow

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your Machine Tailer interview:

1. Research the Company and Position

- Gather information about the company’s size, industry, and products

- Review the job description carefully to understand the specific requirements of the role

- Identify any unique skills or experience that the company is looking for

2. Practice Your Answers

- Prepare examples from your past experience that demonstrate your skills in machine operation, fabric handling, and garment assembly

- Practice answering common interview questions, such as “Why are you interested in working as a Machine Tailer?” and “What are your strengths and weaknesses?”

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples

3. Showcase Your Skills

- If possible, bring a portfolio or sample garments that demonstrate your sewing skills

- Be prepared to discuss your proficiency with different types of sewing machines and fabrics

- Highlight any certifications or training you have received in sewing or garment production

4. Prepare Industry-Specific Questions

- Ask questions about the company’s production processes, quality standards, and sustainability practices

- Inquire about opportunities for professional development and advancement

- Show your enthusiasm for the industry and your desire to learn and grow

5. Dress Professionally and Arrive on Time

- Make a good impression by dressing appropriately for the interview

- Arrive on time to demonstrate your respect for the hiring manager’s schedule

- Be polite and respectful throughout the interview process

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Machine Tailer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Machine Tailer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.