Are you gearing up for an interview for a Machine Taper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Machine Taper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

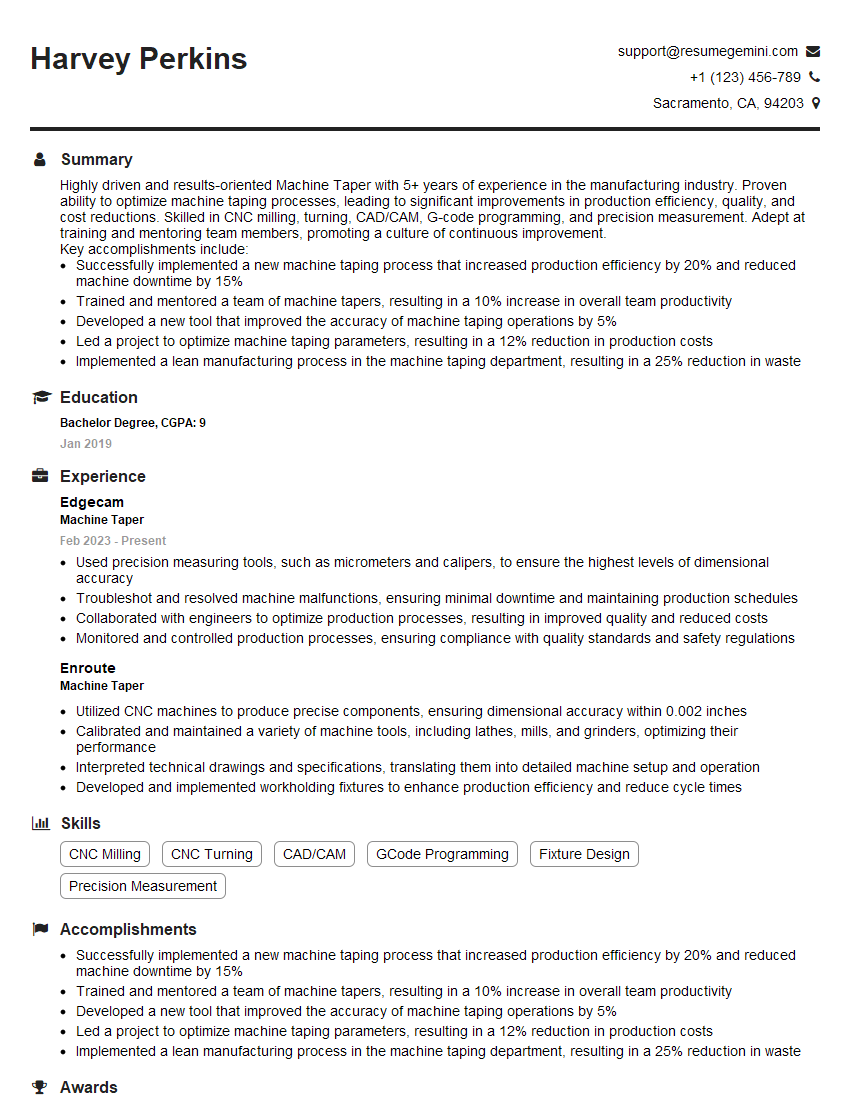

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Taper

1. Explain the different types of machine tapers and their applications?

- Morse taper: Used for holding cutting tools in machine tools, such as drills, reamers, and end mills.

- Brown & Sharpe taper: Used for holding cutting tools in machine tools, such as milling cutters, boring bars, and collet chucks.

- Jarno taper: Used for holding workpieces in machine tools, such as lathes, milling machines, and grinders.

- Jacobs taper: Used for holding cutting tools in hand tools, such as drills, reamers, and taps.

2. Describe the process of grinding a machine taper?

of the answer: Preparation

- Select the appropriate grinding wheel for the material being ground.

- Dress the grinding wheel to the desired shape and size.

- Mount the workpiece on the grinding machine.

Subheading of the answer: Grinding

- Set the grinding machine to the correct speed and feed rate.

- Grind the taper using a steady, even motion.

- Check the taper regularly using a taper gauge.

Subheading of the answer: Finishing

- Finish the taper to the desired surface finish.

- Remove the workpiece from the grinding machine.

3. What are the factors that affect the accuracy of a machine taper?

- The accuracy of the grinding machine.

- The skill of the operator.

- The condition of the grinding wheel.

- The material being ground.

4. How do you inspect a machine taper?

- Use a taper gauge to check the taper angle.

- Use a micrometer to check the taper diameter.

- Use a surface plate to check the taper for flatness.

5. What are the common problems that can occur when grinding a machine taper?

- The taper may be out of tolerance.

- The surface finish may be too rough.

- The taper may be burned.

- The taper may be cracked.

6. How do you troubleshoot problems when grinding a machine taper?

- Check the accuracy of the grinding machine.

- Check the skill of the operator.

- Check the condition of the grinding wheel.

- Check the material being ground.

7. What are the safety precautions that should be taken when grinding a machine taper?

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Keep the grinding machine in good condition.

- Use the correct grinding wheel for the material being ground.

- Follow the manufacturer’s instructions for operating the grinding machine.

8. What are the latest developments in machine taper grinding technology?

- CNC grinding machines.

- Laser grinding machines.

- Electrochemical grinding machines.

9. How do you stay up-to-date on the latest developments in machine taper grinding technology?

- Read trade magazines.

- Attend industry conferences and exhibitions.

- Talk to other machine taper grinders.

10. How do you maintain a high level of quality in your machine taper grinding work?

- Use high-quality grinding wheels.

- Use the correct grinding techniques.

- Inspect your work regularly.

- Keep your grinding machine in good condition.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Taper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Taper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Tapers are responsible for operating and maintaining taper machines in a manufacturing setting. They ensure that the machines are set up and operating properly, and that the products being produced meet the required specifications. Some of the key job responsibilities of a Machine Taper include:

1. Operating Taper Machines

Machine Tapers are responsible for operating a variety of taper machines, including manual, semi-automatic, and fully-automatic machines. They must be able to set up and operate the machines according to the manufacturer’s specifications, and to produce products that meet the required quality standards.

- Set up and operate taper machines according to manufacturer’s specifications.

- Produce products that meet the required quality standards.

2. Machine Maintenance

.Machine Tapers are also responsible for maintaining the taper machines they operate. This includes performing regular inspections, cleaning and lubricating the machines, and making minor repairs. They must also be able to identify and diagnose problems with the machines, and to take corrective action to prevent further damage.

- Perform regular inspections of taper machines.

- Clean and lubricate taper machines.

- Make minor repairs to taper machines.

- Identify and diagnose problems with taper machines.

- Take corrective action to prevent further damage to taper machines.

3. Quality Control

Machine Tapers are responsible for ensuring that the products they produce meet the required quality standards. This includes inspecting the products for defects, and taking corrective action to prevent defective products from being shipped to customers.

- Inspect products for defects.

- Take corrective action to prevent defective products from being shipped to customers.

4. Safety

Machine Tapers must be aware of the safety hazards associated with operating taper machines. They must follow all safety procedures, and wear appropriate safety gear to protect themselves from injury.

- Follow all safety procedures.

- Wear appropriate safety gear.

Interview Tips

In order to ace an interview for a Machine Taper position, it is important to be prepared to answer questions about your experience and qualifications. You should also be familiar with the company and the position you are applying for.

1. Research the Company

Before the interview, take some time to research the company you are applying to. This will help you to understand the company’s culture, values, and goals. You should also research the specific position you are applying for. This will help you to understand the job requirements and expectations.

- Visit the company’s website.

- Read the company’s annual report.

- Talk to people who work for the company.

2. Prepare Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to prepare answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Prepare answers to common interview questions.

- Practice your answers out loud.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also avoid wearing excessive jewellery or perfume.

- Dress professionally.

- Be clean and well-groomed.

4. Be Confident and Enthusiastic

Confidence and enthusiasm are key to making a good impression in an interview. Be confident in your abilities and qualifications, and show the interviewer that you are enthusiastic about the position and the company.

- Be confident in your abilities and qualifications.

- Show the interviewer that you are enthusiastic about the position and the company.

Next Step:

Now that you’re armed with the knowledge of Machine Taper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machine Taper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini