Feeling lost in a sea of interview questions? Landed that dream interview for Machine Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Machine Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

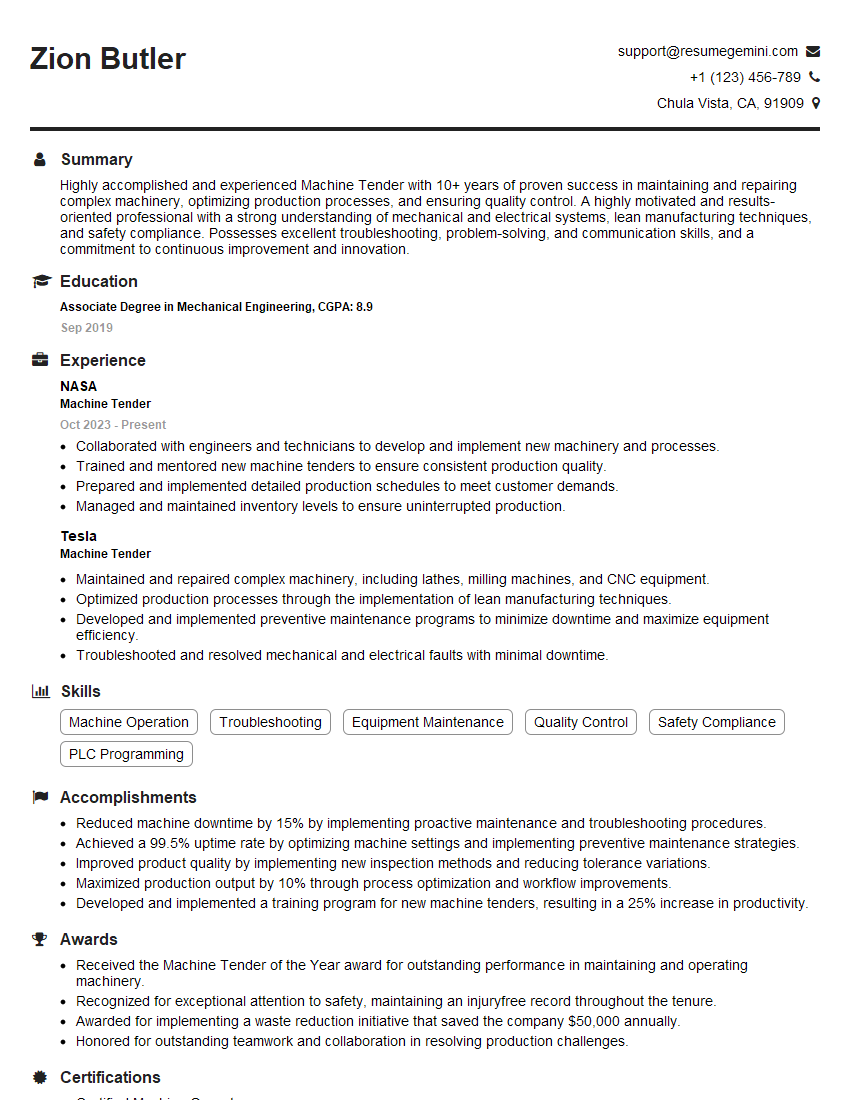

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Tender

1. Explain the steps involved in setting up a new machine for production?

To set up a new machine for production, I follow these steps:

- Read the machine’s manual and specifications to understand its capabilities and requirements.

- Inspect the machine to ensure it is in good condition and all parts are present and accounted for.

- Install the machine in the designated location, ensuring it is level and securely fastened.

- Connect the machine to the necessary power source, utilities, and peripherals.

- Calibrate the machine according to the manufacturer’s instructions to ensure accuracy and precision.

- Load the machine with the appropriate materials or components and set the operating parameters.

- Run test cycles to verify that the machine is functioning properly and producing acceptable output.

- Document the setup process and any adjustments made for future reference.

2. How do you troubleshoot and resolve common machine malfunctions?

Diagnosing the Issue

- Observe the machine’s behavior and error messages to identify potential causes of the malfunction.

- Check for loose connections, damaged components, or any unusual noises or vibrations.

- Refer to the machine’s manual and troubleshooting guides for specific error codes and solutions.

Resolving the Issue

- Replace or repair damaged components as necessary.

- Tighten loose connections or adjust settings to correct any misalignments.

- Clean or lubricate the machine to remove any debris or blockages that may impede operation.

- Reset the machine or perform specific diagnostic procedures to clear error codes and restore functionality.

Preventing Recurrences

- Analyze the root cause of the malfunction to identify any underlying issues or maintenance needs.

- Implement preventive maintenance measures to reduce the likelihood of similar issues in the future.

3. How do you ensure the quality of products produced by the machine you operate?

I maintain the quality of products by:

- Regularly inspecting and calibrating the machine to ensure accuracy and precision.

- Monitoring the production process and making adjustments as needed to maintain product specifications.

- Performing quality control checks on samples of the output to verify conformance to standards.

- Documenting all quality checks and any issues or adjustments made to ensure traceability and accountability.

- Adhering to established quality management procedures and protocols.

4. How do you prioritize tasks and manage your time effectively while operating multiple machines?

To prioritize tasks and manage my time effectively, I:

- Create a daily or weekly schedule that outlines the tasks that need to be completed.

- Prioritize tasks based on urgency, importance, and deadlines.

- Break down complex tasks into smaller, manageable steps.

- Monitor the progress of tasks and make adjustments to the schedule as needed.

- Delegate tasks to other team members when possible to improve efficiency.

- Utilize automation tools or technologies to streamline tasks and save time.

5. How do you work effectively as part of a team to achieve production goals?

To work effectively as part of a team, I:

- Communicate openly and clearly with team members to share information and coordinate efforts.

- Collaborate on problem-solving and finding solutions to improve processes and productivity.

- Support other team members by providing assistance and sharing knowledge.

- Respect diversity of perspectives and work styles to foster a positive and inclusive work environment.

- Contribute to team meetings and discussions to share ideas and provide input.

6. Describe your experience with different types of machinery and equipment.

I have experience with various types of machinery and equipment, including:

- Computer Numerical Control (CNC) machines, such as lathes, mills, and grinders.

- Injection molding machines and extruders.

- Automated assembly lines and robotic systems.

- Packaging and labeling machinery.

- Conveyor systems and material handling equipment.

7. Explain how you stay up-to-date on the latest industry trends and advancements.

To stay up-to-date on the latest industry trends and advancements, I:

- Attend industry conferences, workshops, and training sessions.

- Read industry publications, journals, and online resources.

- Network with other professionals in the field.

- Participate in online forums and discussion groups.

- Explore new technologies and innovations through research and experimentation.

8. How do you ensure the safety of yourself and others while operating machinery?

To ensure the safety of myself and others while operating machinery, I:

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Follow established safety protocols and procedures.

- Inspect machinery before operating it to identify any potential hazards.

- Operate machinery at a safe speed and within specified limits.

- Be aware of the location of emergency stop buttons and other safety features.

- Report any unsafe conditions or concerns to my supervisor immediately.

9. How do you handle unexpected downtime or emergencies?

When faced with unexpected downtime or emergencies, I:

- Remain calm and assess the situation.

- Identify the cause of the downtime or emergency and take immediate action to minimize its impact.

- Communicate the situation to my supervisor or other team members.

- Follow established emergency procedures to ensure the safety of myself and others.

- Document the incident and any actions taken to resolve it for future analysis and improvement.

10. How do you measure your performance and identify areas for improvement?

To measure my performance and identify areas for improvement, I:

- Set clear goals and objectives.

- Monitor my progress and track key performance indicators (KPIs).

- Analyze my results to identify strengths and weaknesses.

- Seek feedback from my supervisor, colleagues, and customers.

- Participate in training and development opportunities to enhance my skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Tenders are responsible for operating and maintaining complex machines in various industrial settings. Their primary duties include:

1. Machine Operation

Operate and monitor machines, ensuring smooth functioning and adherence to production schedules.

- Start, stop, and adjust machines as needed.

- Load and unload materials or products from machines.

- Monitor machine performance, identify and resolve minor issues.

2. Machine Maintenance

Perform basic maintenance tasks on machines to prevent breakdowns and ensure optimal operation.

- Inspect, clean, lubricate, and adjust machine components.

- Replace worn or damaged parts as required.

- Monitor machine condition and report any issues to supervisors.

3. Quality Control

Inspect products produced by machines to ensure quality standards are met.

- Check for defects, imperfections, or inconsistencies.

- Make adjustments to machines as needed to rectify quality issues.

- Maintain records of quality inspections and report any discrepancies.

4. Safety Procedures

Follow established safety protocols to ensure the well-being of themselves and others.

- Operate machines according to safety guidelines.

- Wear appropriate protective gear and clothing.

- Report any safety hazards or potential risks.

Interview Tips

Preparing for a Machine Tender interview requires thorough research and a solid understanding of the industry. Here are some tips to help you ace the interview:

1. Research the Company and Position

Learn about the company’s products, services, and industry standing. Familiarize yourself with the specific responsibilities of the Machine Tender role.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay informed about best practices.

- Network with professionals in the field to gain insights into the industry and the role.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in machine operation and maintenance. Showcase your ability to troubleshoot and resolve machine issues.

- Quantify your accomplishments with specific examples.

- Explain how your previous experience has prepared you for this role.

- Be prepared to discuss your knowledge of relevant equipment and technologies.

3. Demonstrate Safety Awareness

Discuss your commitment to safety and adherence to established protocols. Highlight your experience in identifying and mitigating potential hazards.

- Describe your understanding of safety regulations and best practices.

- Explain how you have implemented safety measures in previous roles.

- Be prepared to discuss your awareness of industry safety standards.

4. Prepare for Industry-Specific Questions

Expect questions related to specific industry practices and equipment. Be prepared to provide detailed answers based on your knowledge and experience.

- Research common industry challenges and solutions.

- Prepare examples of how you have overcome machine-related issues.

- Stay updated on advancements in machine technology and automation.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.