Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Tool Builder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

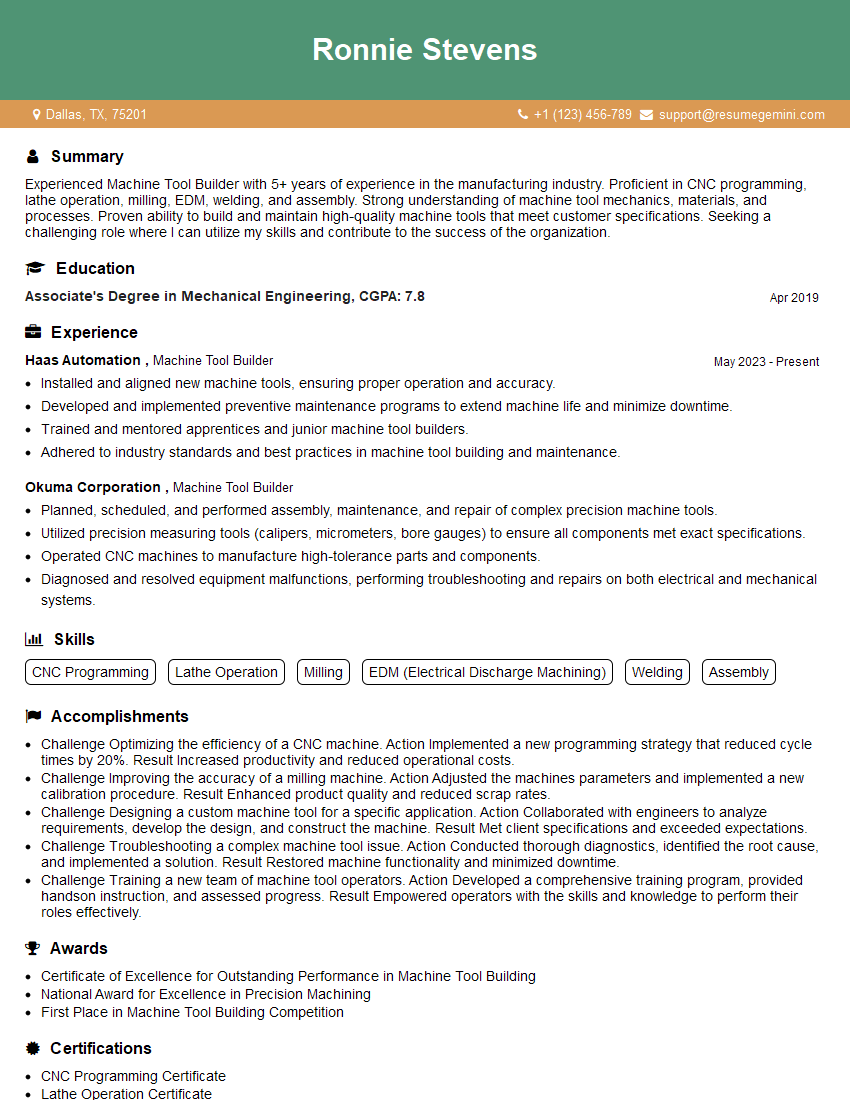

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Tool Builder

1. What are the different types of machine tools used in building machines?

There are numerous types of machine tools used in building machines. Some of the most common types include:

- Lathes: Used for turning and boring operations.

- Milling machines: Used for cutting and shaping operations.

- Drilling machines: Used for creating holes.

- Grinding machines: Used for finishing operations.

- Presses: Used for shaping and forming operations.

- Welding machines: Used for joining metal parts.

- CNC machines: Used for automated manufacturing processes.

2. What are the key features and components of a CNC machine?

CNC (Computer Numerical Control) machines are computer-controlled machines that use programmed instructions to automate manufacturing processes. Key features and components of a CNC machine include:

Control unit:

- Processes the program instructions and converts them into commands for the machine.

Servo drives:

- Control the movement of the machine axes.

Spindle:

- Holds and rotates the cutting tool.

Tool changer:

- Automatically changes the cutting tools as needed.

Workpiece table:

- Holds the workpiece being machined.

3. What are the advantages and disadvantages of using CNC machines?

CNC machines offer several advantages:

- Improved accuracy and precision.

- Increased productivity.

- Reduced labor costs.

- Greater flexibility and versatility.

However, there are also some disadvantages to using CNC machines:

- High initial investment.

- Need for skilled operators.

- Maintenance and repair costs.

4. What are the typical materials processed by machine tools?

Machine tools are capable of processing a wide range of materials, including:

- Metals: Steel, aluminum, brass, etc.

- Plastics: ABS, PVC, polyethylene, etc.

- Composites: Carbon fiber, fiberglass, etc.

- Wood: Softwoods, hardwoods, etc.

- Glass: Float glass, tempered glass, etc.

5. What are the essential safety precautions to observe when operating a machine tool?

Safety is paramount when operating a machine tool. Essential safety precautions include:

- Wear appropriate personal protective equipment (PPE).

- Ensure the machine is properly grounded and guarded.

- Follow all operating procedures carefully.

- Never reach into the machine while it is operating.

- Report any malfunction or unsafe condition immediately.

6. How do you maintain and troubleshoot machine tools?

Regular maintenance is crucial for ensuring the optimal performance of machine tools. Maintenance tasks include:

- Cleaning and lubrication.

- Checking for wear and tear.

- Replacing worn-out components.

Troubleshooting involves identifying and resolving any malfunctions or performance issues. Common troubleshooting steps include:

- Checking electrical connections.

- Inspecting mechanical components.

- Running diagnostic tests.

- Consulting technical manuals.

7. What are the quality control procedures implemented in machine tool building?

Quality control procedures are essential for ensuring the quality and accuracy of machine tools. These procedures include:

- Inspection of raw materials.

- Regular calibration of machines.

- Testing of finished products.

- Statistical process control (SPC) techniques.

- Continuous improvement and quality assurance programs.

8. What are the emerging trends in machine tool technology?

The machine tool industry is constantly evolving. Emerging trends include:

- Increased use of automation and robotics.

- Integration of additive manufacturing (3D printing).

- Development of more sustainable and energy-efficient machines.

- Use of artificial intelligence (AI) for machine optimization and decision-making.

9. How do you stay updated with the latest technological advancements in your field?

Keeping up with technological advancements is crucial in any field. I make a conscious effort to:

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Network with other professionals in my field.

- Explore online resources and webinars.

- Engage in continuous learning and professional development.

10. How do you handle working under pressure and tight deadlines?

Working under pressure and tight deadlines is a common challenge in the machine tool building industry. I manage this pressure by:

- Prioritizing tasks and setting realistic timelines.

- Breaking down large projects into smaller, manageable chunks.

- Delegating tasks and responsibilities effectively.

- Communicating openly with colleagues and supervisors.

- Taking breaks and maintaining a healthy work-life balance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Tool Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Tool Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Tool Builders are responsible for the construction and maintenance of machine tools used in manufacturing processes. They work with a variety of materials, including metal, plastic, and wood, and use a variety of tools and equipment to create precision parts.

1. Machine Assembly

Machine Tool Builders assemble and install machine tools according to blueprints and specifications. They may also be responsible for troubleshooting and repairing machines.

- Assemble and install machine tools according to blueprints and specifications.

- Troubleshoot and repair machines.

2. Machine Operation

Machine Tool Builders operate machine tools to create precision parts. They must be able to read and interpret blueprints and specifications, and they must have a good understanding of the operation of the machines they are using.

- Operate machine tools to create precision parts.

- Read and interpret blueprints and specifications.

3. Machine Maintenance

Machine Tool Builders perform maintenance on machine tools to ensure that they are operating properly. They may also be responsible for calibrating and adjusting machines, and for replacing worn or damaged parts.

- Perform maintenance on machine tools to ensure that they are operating properly.

- Calibrate and adjust machines.

- Replace worn or damaged parts.

4. Quality Control

Machine Tool Builders inspect parts to ensure that they meet quality standards. They may also be responsible for developing and implementing quality control procedures.

- Inspect parts to ensure that they meet quality standards.

- Develop and implement quality control procedures.

Interview Tips

Preparing for an interview for a Machine Tool Builder position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website and read about their history, mission, and products.

- Review the job description and make a list of the skills and qualifications that the company is looking for.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is a good idea to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Start by brainstorming a list of common interview questions.

- Write out your answers to each question and practice saying them out loud.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience as a Machine Tool Builder. Be prepared to discuss your skills and qualifications, as well as your experience with different types of machine tools.

- Highlight your experience with the specific types of machine tools that the company uses.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

4. Be Enthusiastic and Positive

The interviewer will be looking for someone who is enthusiastic about the position and who is a positive addition to the team. Be sure to show your interest in the company and the position, and be positive about your ability to do the job.

- Smile and make eye contact with the interviewer.

- Be confident in your answers and your ability to do the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Tool Builder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.