Feeling lost in a sea of interview questions? Landed that dream interview for Machine Try Out Setter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Machine Try Out Setter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

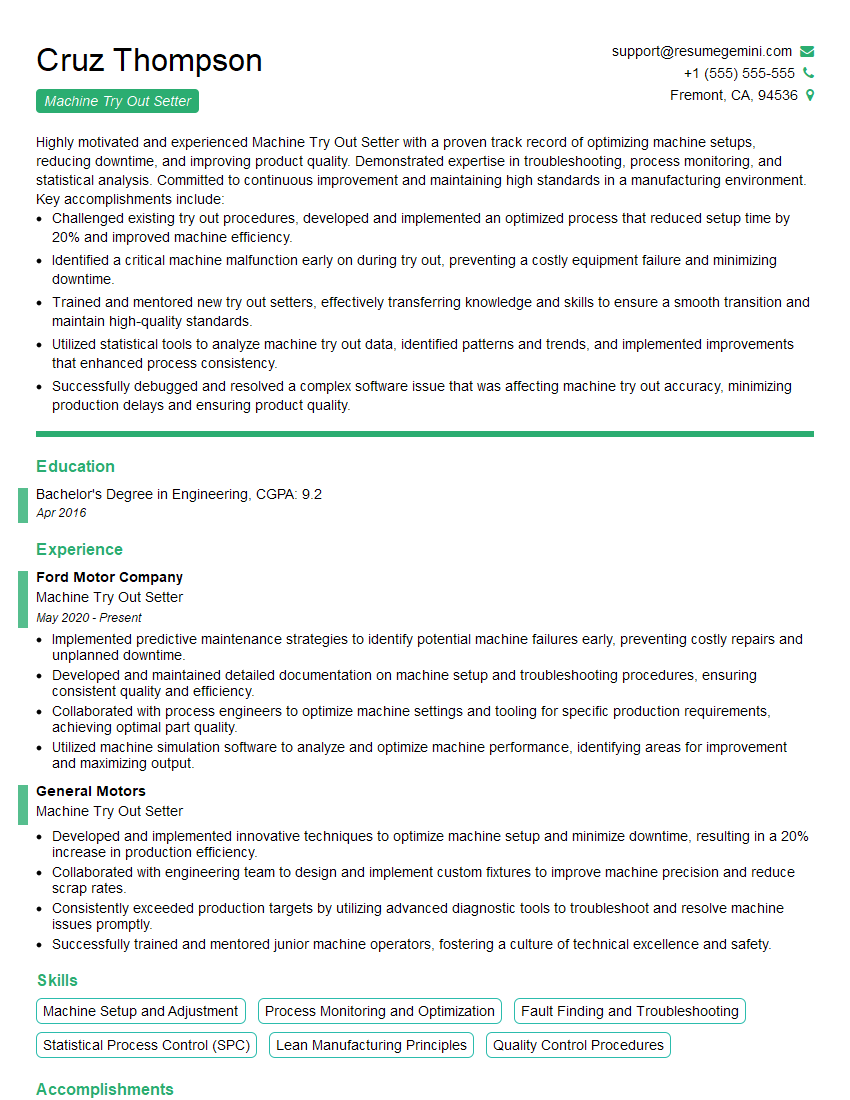

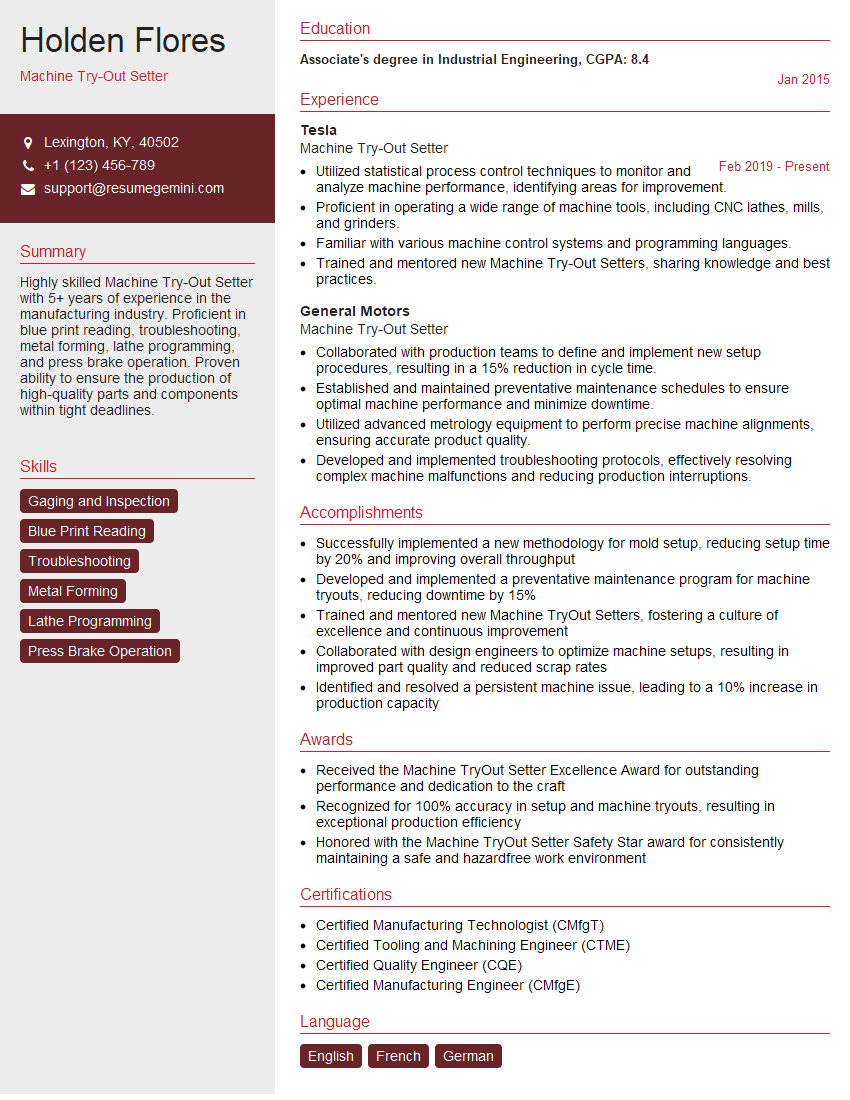

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Try Out Setter

1. What are the key responsibilities of a Machine Try Out Setter?

- Setting up and operating machine try out equipment.

- Monitoring and adjusting machine settings to ensure optimal performance.

- Analyzing data and making adjustments to improve machine efficiency.

- Maintaining and repairing machine try out equipment.

- Training other employees on machine try out procedures.

2. What are the different types of machine try out equipment?

Types of Machine Try Out Equipment

- Tensile testing machines

- Compression testing machines

- Flexural testing machines

- Impact testing machines

- Hardness testing machines

Functions of Machine Try Out Equipment

- Tensile testing machines measure the tensile strength and elongation of materials.

- Compression testing machines measure the compressive strength and yield strength of materials.

- Flexural testing machines measure the bending strength and modulus of elasticity of materials.

- Impact testing machines measure the impact resistance of materials.

- Hardness testing machines measure the hardness of materials.

3. What are the important safety precautions to be observed when operating a machine try out equipment?

- Wear appropriate safety gear, including safety glasses, gloves, and hearing protection.

- Never operate the equipment without proper training.

- Always follow the manufacturer’s instructions for operation and maintenance.

- Keep the work area clean and free of tripping hazards.

- Never leave the equipment unattended while it is running.

4. What are the common problems that can occur when operating a machine try out equipment?

Common problems that can occur when operating a machine try out equipment include:

- Equipment malfunctions

- Improperly calibrated equipment

- Operator errors

- Material defects

- Environmental factors

5. How do you troubleshoot and resolve problems with machine try out equipment?

To troubleshoot and resolve problems with machine try out equipment, the following steps can be taken:

- Identify the problem.

- Consult the manufacturer’s manual.

- Check for loose connections or damaged parts.

- Calibrate the equipment.

- Contact the manufacturer for assistance.

6. How do you maintain and calibrate machine try out equipment?

To maintain and calibrate machine try out equipment, the following steps can be taken:

- Clean the equipment regularly.

- Lubricate the moving parts.

- Check the calibration of the equipment regularly.

- Perform preventive maintenance tasks as recommended by the manufacturer.

7. What are the different types of materials that can be tested using machine try out equipment?

The different types of materials that can be tested using machine try out equipment include:

- Metals

- Plastics

- Ceramics

- Composites

- Wood

- Concrete

8. What are the different test methods that can be performed using machine try out equipment?

The different test methods that can be performed using machine try out equipment include:

- Tensile testing

- Compression testing

- Flexural testing

- Impact testing

- Hardness testing

9. What are the advantages of using machine try out equipment?

The advantages of using machine try out equipment include:

- Increased accuracy and repeatability of tests.

- Reduced testing time.

- Improved safety.

- Elimination of human error.

- Automated data collection and analysis.

10. What are the disadvantages of using machine try out equipment?

The disadvantages of using machine try out equipment include:

- High cost.

- Complexity of operation.

- Requirement for skilled operators.

- Limited testing capabilities.

- Potential for errors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Try Out Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Try Out Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Try Out Setters play a pivotal role in ensuring the smooth operation of production lines. Their primary responsibilities include:

1. Setting Up and Optimizing Machines

Set up and configure production machines according to specified parameters and production schedules.

- Calibrate and adjust machines to ensure accurate and consistent performance.

- Optimize machine settings to increase production efficiency and minimize downtime.

2. Running Test Runs and Verifying Production

Conduct trial runs to test machine performance and identify any potential issues.

- Monitor and evaluate production output to ensure it meets quality standards.

- Troubleshoot and rectify any deviations or defects in the production process.

3. Maintaining Machines and Tools

Perform routine maintenance and cleaning of machines to prolong their operational life.

- Inspect and replace worn or damaged parts as necessary.

- Maintain a clean and organized work area to ensure safety and efficiency.

4. Collaborating with Production Teams

Work closely with production supervisors, engineers, and operators to coordinate production activities.

- Provide technical support and guidance to ensure smooth production flow.

- Share knowledge and best practices with team members to improve overall performance.

Interview Tips

To ace the interview for the Machine Try Out Setter position, follow these tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and industry reputation.

- Research the specific responsibilities of the Machine Try Out Setter role.

- Prepare questions to demonstrate your understanding and interest in the position.

2. Highlight Your Technical Skills

Emphasize your expertise in setting up, optimizing, and troubleshooting production machines.

- Provide specific examples of your ability to resolve production issues and enhance machine performance.

- Discuss your knowledge of mechanical, electrical, and hydraulic systems.

3. Demonstrate Your Problem-Solving Abilities

Showcase your ability to identify and solve production problems quickly and effectively.

- Share examples of how you have used analytical thinking and troubleshooting skills to resolve complex issues.

- Emphasize your ability to work under pressure and make timely decisions.

4. Showcase Your Communication Skills

Highlight your ability to communicate effectively with production teams and supervisors.

- Provide examples of how you have successfully collaborated with others to achieve production goals.

- Demonstrate your ability to clearly explain technical concepts and provide instructions to team members.

5. Prepare for Common Interview Questions

Practice answering common interview questions, such as:

- Tell me about your experience in setting up and optimizing production machines.

- Describe a situation where you successfully resolved a complex production issue.

- How do you ensure that machines are maintained and operated safely?

- Why are you interested in this role and our company?

- What are your strengths and weaknesses as a Machine Try Out Setter?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Try Out Setter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!