Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machine Turner interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machine Turner so you can tailor your answers to impress potential employers.

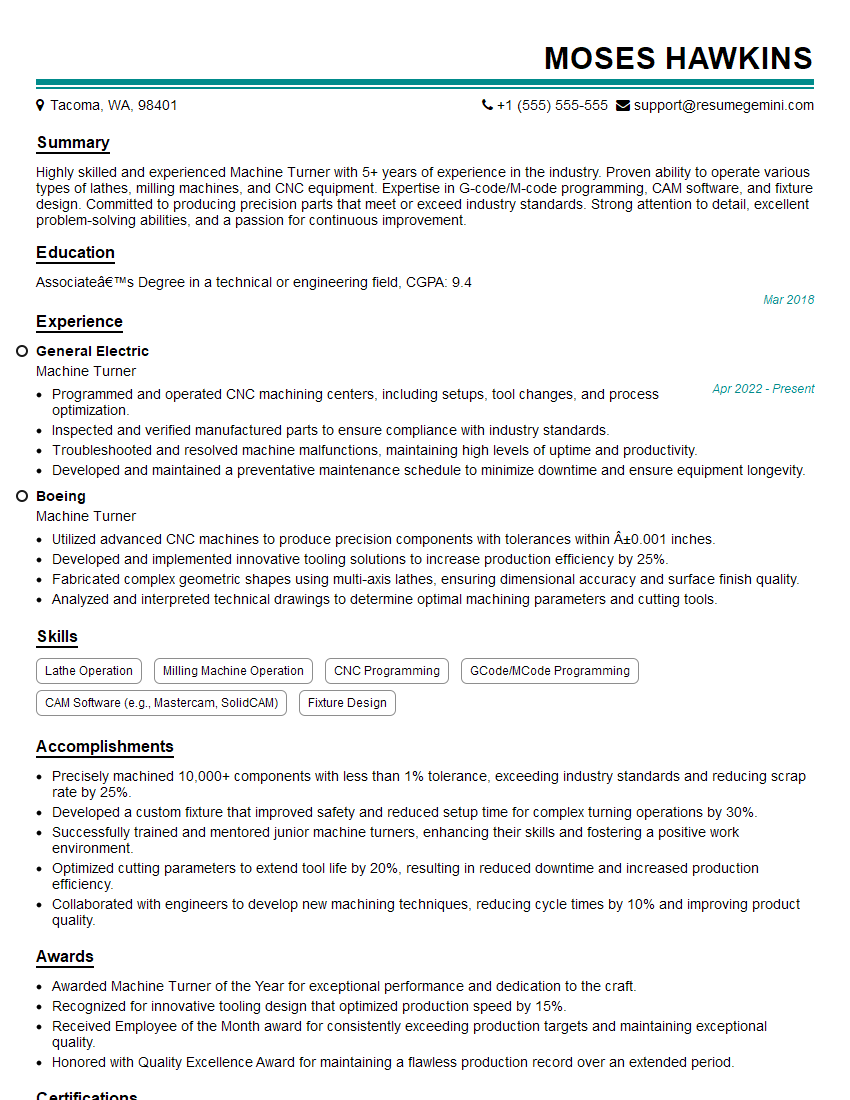

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Turner

1. What are the different types of lathes used in machine turning?

There are various types of lathes used in machine turning, including:

- Engine Lathe: Designed for general-purpose turning operations.

- Turret Lathe: Equipped with a turret that can hold multiple tools for efficient machining.

- CNC Lathe: Computer-controlled lathe that automates turning processes.

- Swiss Lathe: Precision lathe used for small, complex parts with high accuracy.

- Vertical Lathe: Lathe with the workpiece mounted vertically, suitable for large, heavy parts.

2. Explain the process of setting up a workpiece on a lathe.

Centering and Clamping

- Center the workpiece between headstock and tailstock.

- Secure the workpiece using chucks or collets.

Establishing Datum and Reference Points

- Use a dial indicator to establish a reference point for tool positioning.

- Mount a workpiece stop or follow rest to control the length of the cut.

3. Describe the different types of cutting tools used in machine turning.

Machine turning involves various cutting tools, including:

- Turning Tools: Designed for external and internal turning operations.

- Boring Tools: Used for enlarging holes or creating cylindrical bores.

- Facing Tools: For creating flat surfaces on the end of the workpiece.

- Grooving Tools: For cutting grooves or slots into the workpiece.

- Threading Tools: Used for creating threads on the workpiece.

4. How do you calculate the cutting speed and feed rate for a turning operation?

Cutting speed calculation:

- V = πDN / 12 (ft/min)

- V = Cutting speed in feet per minute

- D = Workpiece diameter in inches

- N = Spindle speed in revolutions per minute

Feed rate calculation:

- F = f / N (inches per revolution)

- F = Feed rate

- f = Feed per tooth

- N = Spindle speed in revolutions per minute

5. What are the common defects encountered in machine turning, and how do you prevent them?

Common turning defects include:

- Taper: Caused by misalignment of the tailstock or improper tool positioning.

- Chatter: Resulting from excessive tool vibration, which can be minimized by using sharp tools or adjusting cutting parameters.

- Undercut: Occurs when the cutting tool removes too much material, remedied by reducing the feed rate or using a smaller tool.

6. How do you inspect the accuracy of a machined workpiece?

- Use a dial indicator or micrometer to measure dimensions.

- Check surface finish and tolerances using a comparator or profilometer.

- Perform thread inspection using thread gauges or a coordinate measuring machine (CMM).

7. What is the difference between a roughing cut and a finishing cut?

- Roughing Cut: Initial cutting operation that removes most of the excess material.

- Finishing Cut: Subsequent cutting operation that creates the final dimensions and desired surface finish.

8. What is the importance of using coolants in machine turning?

- Lubrication: Reduces friction and heat, extending tool life.

- Cooling: Prevents workpiece and tool overheating, maintaining workpiece accuracy.

- Swarf Removal: Helps carry away metal chips from the cutting area.

9. Explain the process of threading on a lathe.

- Select the appropriate threading tool for the desired thread profile.

- Set the lathe to the correct thread pitch and cutting speed.

- Engage the threading tool and feed it gradually into the workpiece.

- Monitor the thread depth and make adjustments as needed.

10. What are the safety precautions to follow when operating a lathe?

- Wear appropriate safety gear, including safety glasses and gloves.

- Ensure the lathe is properly guarded and grounded.

- Keep the work area clean and free of debris.

- Be aware of the rotating chuck and moving parts.

- Stop the lathe before making adjustments or changing tools.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Turner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Turner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Turners are highly skilled professionals who play a crucial role in the manufacturing industry by operating and maintaining a variety of machines used to shape and finish metal components.

1. Machine Setup and Operation

• Mount and secure workpieces on the machine

• Adjust cutting tools and select appropriate speeds and feeds

• Monitor machines during operation and make necessary adjustments

2. Quality Assurance

• Inspect finished parts and ensure they meet specifications

• Use measuring tools and gauges to verify dimensions and tolerances

• Identify and correct defects or non-conformances

3. Maintenance and Troubleshooting

• Perform routine maintenance on machines

• Diagnose and resolve machine malfunctions

• Maintain inventory of tools and supplies

4. Process Improvement

• Analyze production processes and identify opportunities for improvement

• Implement process changes to enhance efficiency and quality

• Collaborate with engineers and other technical staff to optimize machine performance

Interview Tips

Preparing for a Machine Turner interview requires a combination of technical knowledge and professional presentation skills. Here are some key tips to help you ace the interview:

1. Research the Company and Position

• Thoroughly review the company’s website and social media pages

• Understand the company’s products, services, and industry

• Familiarize yourself with the specific job responsibilities and requirements

2. Highlight Your Skills and Experience

• Quantify your accomplishments and provide specific examples of your skills

• Discuss your experience in machine setup, operation, and maintenance

• Emphasize your quality control experience and ability to meet tight tolerances

3. Showcase Your Technical Knowledge

• Be prepared to discuss the different types of machines you have operated

• Explain your understanding of cutting tools, speeds, and feeds

• Describe your experience in troubleshooting and resolving machine issues

4. Demonstrate Your Professionalism

• Arrive on time, dress appropriately, and maintain a positive attitude

• Be respectful and attentive during the interview

• Ask thoughtful questions that demonstrate your interest in the position and the company

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Machine Turner role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.