Are you gearing up for an interview for a Machine Welder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Machine Welder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

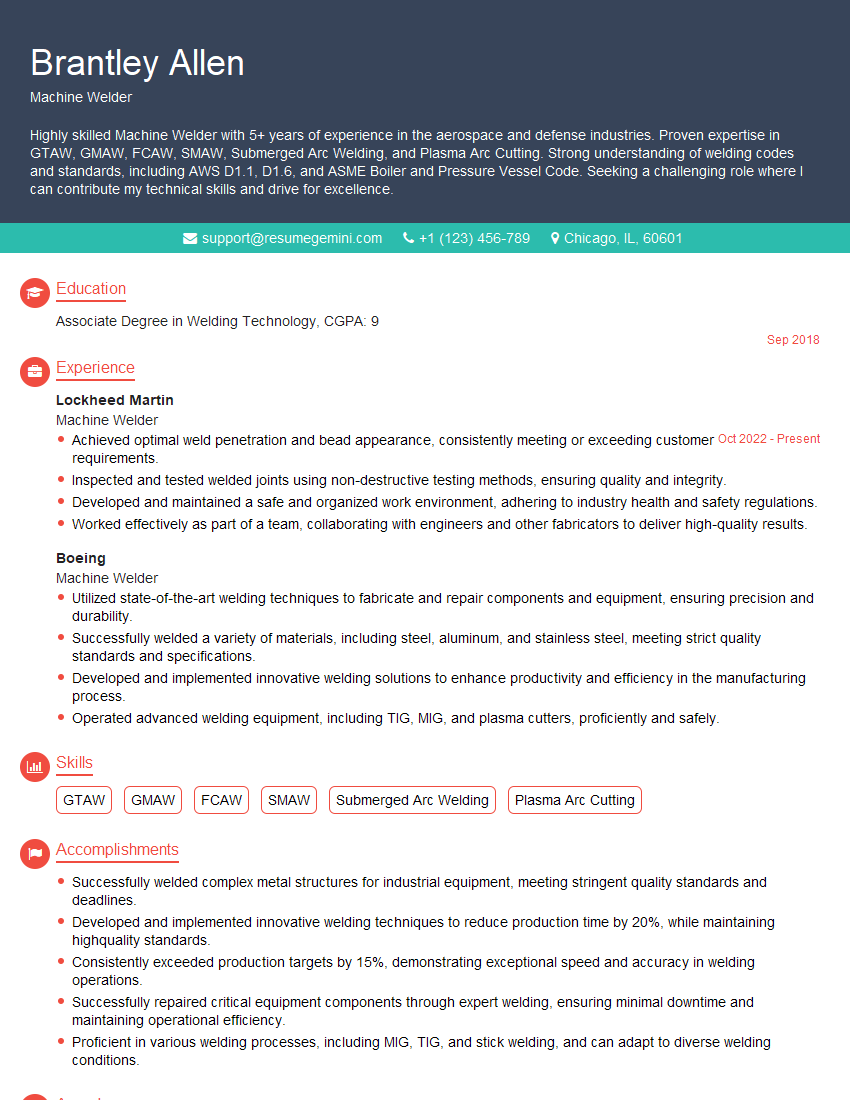

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Welder

1. What are the different types of welding machines?

There are many different types of welding machines available, each with its own advantages and disadvantages. Some of the most common types include:

- Arc welding machines: These machines use an electric arc to melt the metal and create a weld. They are commonly used for welding metal to metal.

- Gas welding machines: These machines use a flame to melt the metal and create a weld. They are commonly used for welding thin metals.

- Laser welding machines: These machines use a laser beam to melt the metal and create a weld. They are commonly used for welding small, precise parts.

2. What are the different types of welding joints?

There are many different types of welding joints, each with its own unique purpose. Some of the most common types include:

- Butt joint: This joint is created by placing two pieces of metal together and welding them along their edges.

- Edge joint: This joint is created by placing two pieces of metal together and welding them along their edges at an angle.

- Corner joint: This joint is created by placing two pieces of metal together at a right angle and welding them together.

- Tee joint: This joint is created by placing one piece of metal perpendicular to another piece of metal and welding them together.

3. What are the different types of welding electrodes?

There are many different types of welding electrodes, each with its own unique properties. Some of the most common types include:

- Shielded metal arc welding (SMAW) electrodes: These electrodes are made of a consumable metal material, such as steel or stainless steel. They are coated with a flux material that helps to protect the weld from contamination.

- Gas tungsten arc welding (GTAW) electrodes: These electrodes are made of a non-consumable metal material, such as tungsten. They are used to create high-quality welds.

- Gas metal arc welding (GMAW) electrodes: These electrodes are made of a consumable metal material, such as steel or aluminum. They are used with a shielding gas to protect the weld from contamination.

4. What are the safety precautions that must be taken when welding?

Welding can be a dangerous activity if proper safety precautions are not taken. Some of the most important safety precautions include:

- Wear proper protective clothing: This includes a welding helmet, gloves, and leather jacket.

- Use a well-ventilated area: Welding fumes can be harmful if inhaled.

- Keep the welding area clean: This will help to prevent fires.

- Never weld on live electrical equipment: This could cause an electrical shock.

5. What are the common defects that can occur in welds?

There are many different types of defects that can occur in welds, including:

- Cracks: These are breaks in the weld metal that can be caused by a variety of factors.

- Porosity: This is the presence of gas bubbles in the weld metal that can weaken the weld.

- Inclusions: These are foreign materials that are trapped in the weld metal that can weaken the weld.

- Undercuts: These are areas where the weld metal has not fused properly with the base metal.

6. What are the different methods for testing welds?

There are many different methods for testing welds, including:

- Visual inspection: This is a simple and inexpensive method for checking for defects in welds.

- Radiographic testing: This method uses X-rays to check for defects in welds.

- Ultrasonic testing: This method uses sound waves to check for defects in welds.

- Dye penetrant testing: This method uses a dye to check for cracks in welds.

7. What are the different types of welding codes and standards?

There are many different types of welding codes and standards, including:

- AWS D1.1: This code is used for the welding of structural steel.

- AWS D1.3: This code is used for the welding of stainless steel.

- ASME Boiler and Pressure Vessel Code: This code is used for the welding of boilers and pressure vessels.

- API 1104: This code is used for the welding of pipelines.

8. What are the different types of welding automation systems?

There are many different types of welding automation systems, including:

- Robotic welding systems: These systems use robots to weld parts.

- Automated welding machines: These machines use a computer to control the welding process.

- Welding positioners: These devices are used to hold parts in place while they are being welded.

9. What are the latest trends in welding technology?

Some of the latest trends in welding technology include:

- The use of lasers for welding: Laser welding is a precise and efficient method for welding metals.

- The use of automation for welding: Welding automation systems can improve productivity and quality.

- The use of new materials for welding: New materials are being developed that are stronger and more durable than traditional materials.

10. What are the skills and qualifications that are required to be a successful machine welder?

Some of the skills and qualifications that are required to be a successful machine welder include:

- A strong understanding of welding principles and techniques

- The ability to read and interpret welding drawings

- The ability to set up and operate welding machines

- The ability to inspect and test welds

- A strong work ethic and a commitment to safety

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Welders play a crucial role in various industries by specializing in operating and maintaining automated welding machines. Their primary responsibilities include:

1. Machine Operation

• Setting up, calibrating, and operating automated welding machines

• Monitoring welding processes and making necessary adjustments

• Ensuring the accuracy and precision of weldments

2. Maintenance and Troubleshooting

• Inspecting and maintaining welding equipment, including machines, torches, and fixtures

• Identifying and resolving malfunctions and breakdowns promptly

• Performing routine maintenance tasks to prevent equipment failures

3. Quality Control

• Conducting visual inspections and non-destructive testing to assess weld quality

• Adhering to established welding codes and standards

• Documenting welding parameters and maintaining quality records

4. Safety and Compliance

• Observing safety protocols and wearing appropriate protective gear

• Understanding and complying with industry regulations and environmental standards

• Promoting a safe and efficient work environment

Interview Tips

Preparing thoroughly for a Machine Welder interview is essential to showcase your skills and increase your chances of success. Here are some valuable tips:

1. Research the Company and Role

• Learn about the company’s industry, products, and values

• Review the job description and identify key requirements and responsibilities

• Research the specific welding processes and equipment used in the industry

2. Highlight Your Expertise

• Emphasize your proficiency in operating and maintaining automated welding machines

• Quantify your accomplishments and provide specific examples of your contributions

• Describe your experience with different welding processes and materials

3. Demonstrate Problem-Solving Skills

• Share examples of how you diagnosed and resolved welding-related issues

• Describe your approach to troubleshooting and finding solutions

• Discuss your ability to work independently and as part of a team

4. Prepare for Technical Questions

• Study welding principles, equipment, and safety practices

• Familiarize yourself with industry standards and codes

• Practice answering questions about welding techniques and quality control

Next Step:

Now that you’re armed with the knowledge of Machine Welder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machine Welder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini