Are you gearing up for a career in Machine Wood Sander? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Machine Wood Sander and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

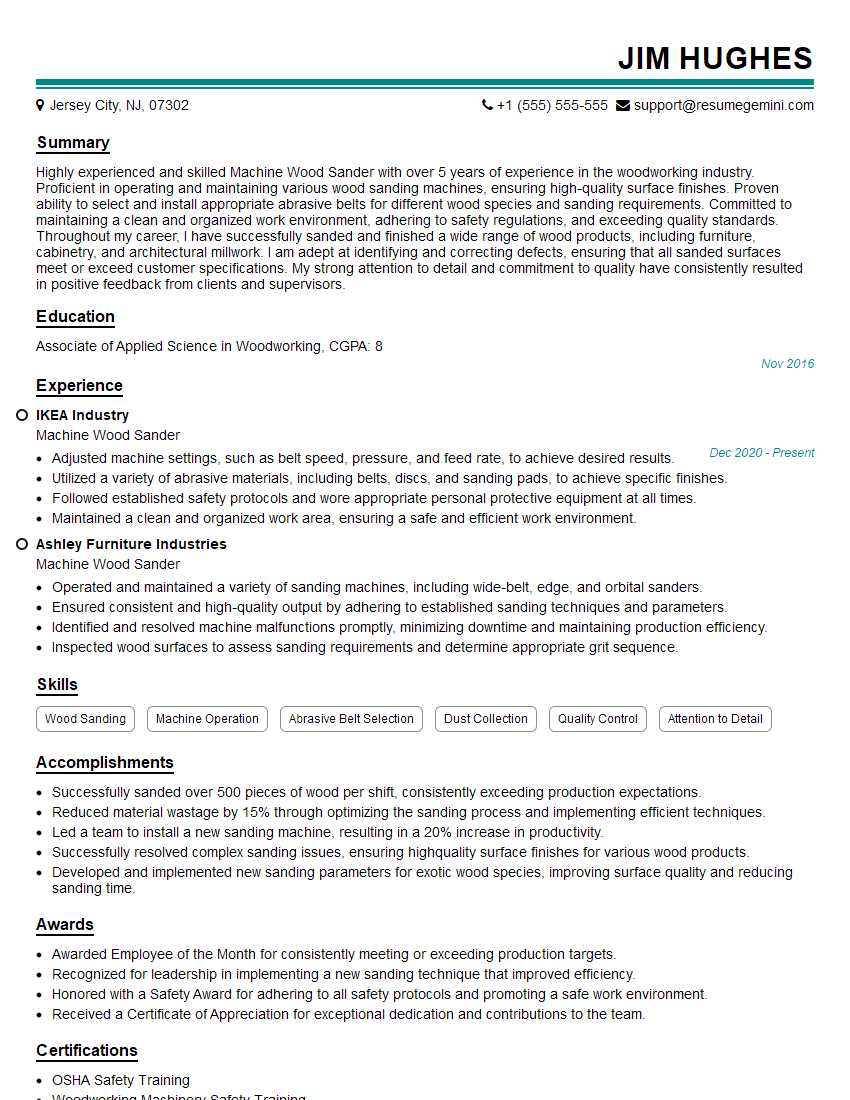

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Wood Sander

1. Describe the different types of abrasive materials used in sanding and their applications.

Here is a description of different types of abrasive materials used in sanding and their applications:

- Aluminum oxide: A versatile abrasive that is commonly used on wood, metal, and plastic. It is available in a variety of grits and is suitable for both hand and machine sanding.

- Silicon carbide: A harder abrasive than aluminum oxide, silicon carbide is ideal for sanding hard materials such as stone and glass. It is also commonly used for wet sanding.

- Ceramic: Ceramic abrasives are made from synthetic materials and offer a long lifespan. They are often used for sanding hard materials such as metal and composites.

- Zirconia alumina: Zirconia alumina abrasives are a blend of zirconia and alumina. They are very durable and are often used for heavy-duty sanding applications.

2. Explain the importance of maintaining the correct belt tension when using a wide belt sander.

Proper belt tension is critical for the following reasons:

- It prevents the belt from slipping, which can lead to uneven sanding and premature belt wear.

- It ensures that the belt is tracking properly, which helps to prevent the workpiece from being damaged.

- It prolongs the life of the belt by reducing the amount of stress on it.

The correct belt tension can be determined by using a tension gauge or by following the manufacturer’s recommendations.

- If the belt is too loose, it will slip and not sand effectively.

- If the belt is too tight, it will put unnecessary stress on the belt and the machine, and could cause the belt to break.

3. How do you calibrate a drum sander to ensure accurate sanding?

Calibrating a drum sander is a crucial step to ensure accurate sanding. Here is how it is done:

- Set the table height: The table height should be adjusted so that the workpiece is level with the center of the drum.

- Adjust the feed rate: The feed rate should be set according to the type of workpiece and the desired finish.

- Use a test piece: Sand a test piece to check the accuracy of the calibration. Make adjustments as needed until the desired finish is achieved.

4. What are the safety precautions that should be taken when operating a spindle sander?

Operating a spindle sander safely requires adherence to the following precautions:

- Wear proper safety gear: This includes safety glasses, earplugs, and a dust mask.

- Secure the workpiece: The workpiece should be securely clamped to the table to prevent it from being thrown.

- Keep hands away from the spindle: Never place your hands near the spinning spindle, as this could result in serious injury.

- Use a push stick: A push stick should be used to feed the workpiece into the sander, rather than using your hands.

- Inspect the machine regularly: Inspect the machine before each use to ensure that it is in good working condition.

5. How do you troubleshoot a sanding machine that is not producing the desired finish?

Troubleshooting a sanding machine that is not producing the desired finish can involve the following steps:

- Check the abrasive belt: Make sure that the abrasive belt is the correct grit and type for the job. Also, check for any damage or wear on the belt.

- Adjust the feed rate: The feed rate may need to be adjusted to achieve the desired finish.

- Inspect the workpiece: The workpiece may have defects or inconsistencies that are affecting the finish.

- Check the machine settings: Make sure that the machine is set up correctly for the type of sanding being done.

- Calibrate the machine: The machine may need to be calibrated to ensure that it is sanding evenly.

6. Explain the different types of sanding patterns and when each one should be used.

The choice of sanding pattern depends on the desired finish and the type of workpiece being sanded.

Here are some common sanding patterns:

- Cross-grain sanding: This pattern is used to remove deep scratches and level the surface.

- With-the-grain sanding: This pattern is used to smooth the surface and prepare it for finishing.

- Circular sanding: This pattern is used to create a smooth, even finish on curved surfaces.

- Random orbital sanding: This pattern is used to create a swirl-free finish on flat surfaces.

7. What is the difference between open-coat and closed-coat sandpaper?

- Open-coat sandpaper: This type of sandpaper has a large spacing between the abrasive grains, which allows for better dust extraction and prevents clogging.

- Closed-coat sandpaper: This type of sandpaper has a smaller spacing between the abrasive grains, which provides a smoother finish but is more prone to clogging.

The choice of open-coat or closed-coat sandpaper depends on the specific application.

- Open-coat sandpaper is ideal for sanding softwoods or materials that produce a lot of dust.

- Closed-coat sandpaper is ideal for sanding hardwoods or materials that require a smooth finish.

8. How do you maintain a sanding machine to ensure optimal performance?

Maintaining a sanding machine involves the following steps:

- Regular cleaning: The machine should be cleaned regularly to remove dust and debris.

- Lubrication: The machine should be lubricated according to the manufacturer’s instructions.

- Belt or disc replacement: The sanding belt or disc should be replaced when it becomes worn or damaged.

- Inspection: The machine should be inspected regularly for any signs of damage or wear.

9. Describe the different types of sanding machines and their applications.

- Belt sander: This type of sander is used for sanding flat surfaces and removing large amounts of material.

- Disc sander: This type of sander is used for sanding curved surfaces and edges.

- Orbital sander: This type of sander is used for sanding flat surfaces and creating a smooth finish.

- Spindle sander: This type of sander is used for sanding small, intricate shapes and edges.

- Drum sander: This type of sander is used for sanding large, flat surfaces.

The choice of sanding machine depends on the specific application and the desired finish.

10. What are the common mistakes that people make when sanding?

- Using the wrong grit sandpaper: Using too coarse of a grit sandpaper can damage the workpiece, while using too fine of a grit sandpaper can take too long to remove material.

- Sanding in the wrong direction: Sanding in the wrong direction can create scratches and damage the workpiece.

- Applying too much pressure: Applying too much pressure can damage the workpiece and make it difficult to achieve a smooth finish.

- Not using a dust mask: Sanding can create a lot of dust, which can be harmful to your health if inhaled.

- Not wearing safety glasses: Sanding can create flying particles, which can damage your eyes if not protected.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Wood Sander.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Wood Sander‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Wood Sanders are responsible for operating specialized sanding machinery to smooth and finish wooden surfaces.

1. Sanding Operations

Operate sanding machines to remove excess wood, smooth surfaces, and achieve desired finishes.

- Set up and adjust machines for different types of sanding operations.

- Select and use appropriate sandpaper grits and sanding techniques.

2. Quality Control

Inspect sanded surfaces for quality and adherence to specifications.

- Identify and correct defects or irregularities in sanding results.

- Ensure that sanded surfaces meet established quality standards.

3. Machine Maintenance

Perform routine maintenance and cleaning of sanding machines.

- Replace worn or damaged parts.

- Lubricate and adjust machines for optimal performance.

4. Safety Compliance

Adhere to established safety protocols while operating sanding machines.

- Wear appropriate personal protective equipment.

- Follow safe work practices to prevent injuries or accidents.

Interview Tips

1. Research the Company and the Role

Gather information about the company’s industry, values, and specific requirements for the Machine Wood Sander position.

- Visit the company website, read industry news, and connect with employees on LinkedIn.

- Review the job description thoroughly to understand the key responsibilities and skills required.

2. Highlight Your Relevant Skills and Experience

Emphasize your experience in operating sanding machines, your knowledge of sanding techniques, and your ability to maintain high-quality standards.

- Quantify your accomplishments using specific metrics or examples.

- Explain how your previous experience has equipped you with the necessary skills for this role.

3. Demonstrate Your Attention to Detail

Machine Wood Sanders play a crucial role in ensuring the quality of finished wooden products.

- Provide examples of your meticulous attention to detail in previous roles or projects.

- Explain how you ensure accuracy and consistency in your work.

4. Emphasize Safety Consciousness

Safety is paramount in any manufacturing environment.

- Explain your understanding of safety protocols and your commitment to adhering to them.

- Share examples of your proactive approach to preventing accidents or injuries.

5. Prepare Thoughtful Questions

Asking well-thought-out questions demonstrates your interest in the role and the company.

- Prepare questions about the company’s growth plans, industry trends, or specific aspects of the job.

- Questions that focus on the company’s commitment to quality and safety are particularly relevant.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Wood Sander interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!