Are you gearing up for an interview for a Machine Woodworking Sander position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Machine Woodworking Sander and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

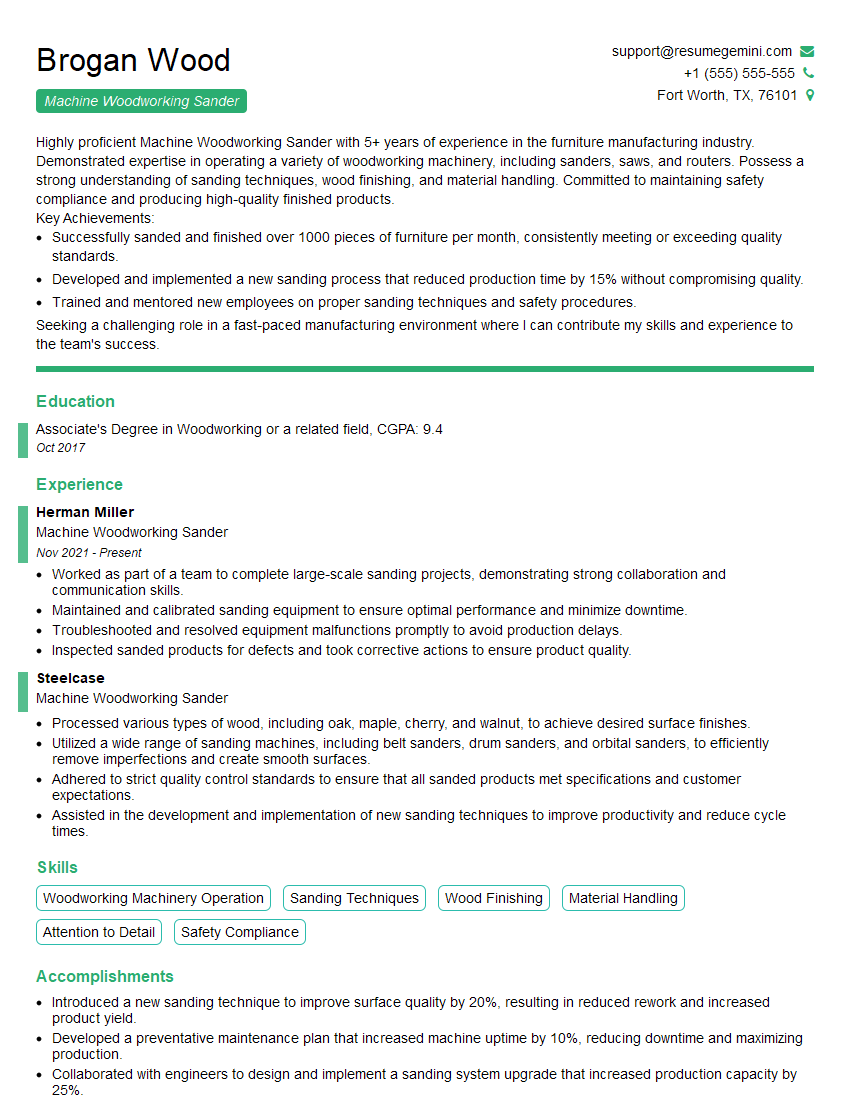

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Woodworking Sander

1. Can you describe the process of sanding wood using a machine sander?

- Prepare the wood surface by removing any dirt or debris.

- Select the appropriate sandpaper grit and attach it to the sander.

- Adjust the sanding speed and pressure to suit the type of wood and desired finish.

- Move the sander in a straight line or circular motion, applying even pressure.

- Inspect the sanded surface for smoothness and any imperfections.

2. How do you determine the correct grit of sandpaper for a specific sanding task?

Factors to Consider:

- Wood type (hardwood, softwood)

- Desired finish (coarse, medium, fine)

- Previous sanding stage (if applicable)

Grit Selection:

- Coarse grit (60-120): Removal of heavy material, rough shaping

- Medium grit (150-220): Smoothing uneven surfaces, removing scratches

- Fine grit (240-400): Final smoothing, preparation for finishing

3. What types of sanders are commonly used for woodworking, and what are their advantages and disadvantages?

- Belt Sander: Wide surface area, efficient for large surfaces; loud and can leave swirls.

- Orbital Sander: Random motion, ideal for contours and curves; may require multiple passes for flat surfaces.

- Palm Sander: Small and portable, good for detailed work; limited surface coverage.

- Edge Sander: Designed to sand edges, provides a consistent finish; specialized tool.

- Drum Sander: Used for precise flat surfaces, requires calibration and expertise.

4. How do you troubleshoot a machine sander that is not sanding effectively?

- Check sandpaper: Ensure it is properly attached and has the correct grit.

- Inspect airflow: Ensure the dust collection system is clean and functioning properly.

- Adjust sanding speed and pressure: Too high or low settings can affect performance.

- Examine the sanding surface: Check for knots or imperfections that may hinder sanding.

- Calibrate the sander: Verify accuracy, especially for drum sanders.

5. Describe the safety precautions you take when operating a machine sander.

- Wear appropriate safety gear (respirator, gloves, eye protection)

- Securely fasten the wood to the work surface

- Inspect the sander before use, check for worn or damaged parts

- Never sand against the grain of the wood

- Avoid over-sanding, which can damage the wood

6. How do you maintain the quality of a machine sander to ensure it performs optimally?

- Regularly clean and maintain the dust collection system

- Inspect and replace sandpaper regularly

- Calibrate the sander periodically to ensure accuracy

- Check for worn or damaged parts and replace them promptly

- Follow manufacturer’s recommendations for maintenance and lubrication

7. Can you describe the different sanding techniques used to achieve specific finishes, such as a smooth or antiqued finish?

- Smooth finish: Use fine-grit sandpaper and move the sander in a straight or circular motion, applying even pressure.

- Antiqued finish: Use coarse-grit sandpaper and apply uneven pressure to create a distressed look.

- Brushed finish: Sand along the grain of the wood using a wire brush to create a textured surface.

8. How do you sand complex surfaces, such as carvings or curved edges?

- Use a palm sander or detail sander with a fine-grit sandpaper.

- Follow the contours of the surface, applying light pressure

- Use a flexible sanding block to conform to irregular shapes.

9. Can you describe the process of sanding wood filler, and what precautions should be taken to avoid damaging the surface?

- Apply wood filler to the desired area and let it dry thoroughly.

- Start sanding with a coarse-grit sandpaper to remove excess filler.

- Gradually switch to finer-grit sandpaper and sand in the direction of the wood grain.

- Inspect the surface regularly to avoid over-sanding or damaging the wood.

10. What techniques do you use to minimize dust generation when sanding wood?

- Utilize a sander with an effective dust collection system.

- Wear a respirator to prevent inhalation of dust particles.

- Sand outdoors or in a well-ventilated area.

- Use a wet-sanding technique, which involves spraying water on the sanding surface.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Woodworking Sander.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Woodworking Sander‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Woodworking Sanders are responsible for operating and maintaining a variety of sanding machines to smooth and finish wood surfaces. They must be able to read blueprints and follow instructions, as well as have a good understanding of the different types of sandpaper and their uses. Machine Woodworking Sanders must also be able to work independently and as part of a team, and must be able to meet production deadlines.

1. Operate Sanding Machines

Machine Woodworking Sanders operate a variety of sanding machines, including belt sanders, disc sanders, and orbital sanders. They must be able to adjust the speed and pressure of the machine to achieve the desired results.

- Set up and operate sanding machines according to blueprints and specifications.

- Adjust the speed and pressure of the machine to achieve the desired results.

- Monitor the sanding process and make adjustments as needed.

2. Maintain Sanding Machines

Machine Woodworking Sanders are responsible for maintaining their sanding machines in good working order. They must be able to identify and troubleshoot problems, and make repairs as needed.

- Clean and lubricate sanding machines regularly.

- Inspect sanding machines for wear and tear.

- Troubleshoot and repair sanding machines as needed.

3. Inspect Wood Surfaces

Machine Woodworking Sanders must be able to inspect wood surfaces to identify any defects. They must also be able to determine the appropriate sanding technique to use for each type of wood.

- Inspect wood surfaces for defects, such as knots, cracks, or scratches.

- Determine the appropriate sanding technique to use for each type of wood.

- Sand wood surfaces to the desired smoothness and finish.

4. Work Independently and as Part of a Team

Machine Woodworking Sanders must be able to work independently and as part of a team. They must be able to follow instructions, meet deadlines, and work with others to achieve the desired results.

- Follow instructions and meet deadlines.

- Work with others to achieve the desired results.

- Contribute to a positive and productive work environment.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Machine Woodworking Sander position:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you understand the specific requirements of the position and what the company is looking for in a candidate.

- Visit the company’s website.

- Read articles about the company in trade publications.

- Talk to people you know who work for the company.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Think about your strengths and weaknesses.

- Prepare examples of your experience that demonstrate your skills and abilities.

- Practice answering questions out loud.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Wear clean, pressed clothes.

- Avoid wearing strong perfumes or colognes.

- Arrive at the interview location 10-15 minutes early.

4. Be Yourself and Be Enthusiastic

The most important thing is to be yourself and be enthusiastic. The interviewer wants to get to know you and understand why you are interested in the position. Be genuine and let your personality shine through. If you are passionate about woodworking, this will come across in your interview.

- Be confident and articulate.

- Make eye contact with the interviewer.

- Smile and show your enthusiasm for the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Woodworking Sander interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!