Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machinery Repair Maintenance Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

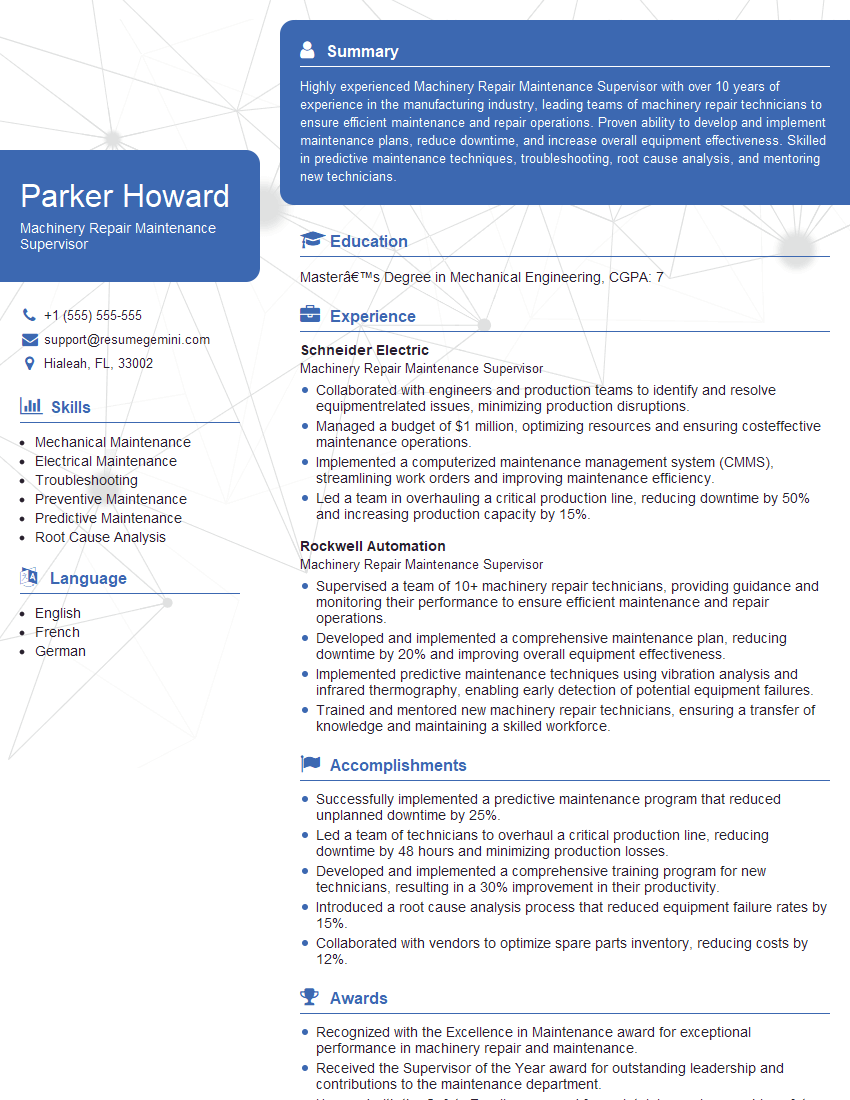

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machinery Repair Maintenance Supervisor

1. What are the key elements of an effective machinery repair and maintenance program?

An effective machinery repair and maintenance program should include the following key elements:

- Preventive maintenance: Conducting regular inspections and maintenance tasks to prevent equipment failures.

- Predictive maintenance: Using data and analytics to predict when equipment is likely to fail and taking proactive measures to prevent it.

- Corrective maintenance: Repairing or replacing equipment that has already failed.

- Emergency maintenance: Responding to unexpected equipment failures that require immediate attention.

- Documentation: Keeping detailed records of all maintenance activities, including the work performed, the parts used, and the date of completion.

2. What are some common challenges faced by machinery repair and maintenance supervisors?

Technical challenges

- Diagnosing and repairing complex equipment

- Staying up-to-date on new technologies and equipment

- Managing a team of maintenance technicians

Operational challenges

- Meeting production targets while maintaining a high level of equipment uptime

- Managing a budget and resources

- Complying with safety regulations

3. What are some best practices for managing a team of maintenance technicians?

Some best practices for managing a team of maintenance technicians include:

- Setting clear expectations and goals

- Providing ongoing training and development

- Empowering technicians to make decisions

- Creating a positive and supportive work environment

- Recognizing and rewarding good performance

4. What are some of the latest trends in machinery repair and maintenance?

Some of the latest trends in machinery repair and maintenance include:

- The use of predictive maintenance technologies

- The use of mobile devices and apps for maintenance tasks

- The use of artificial intelligence (AI) for maintenance decision-making

- The increasing focus on sustainability

- The growing importance of cybersecurity

5. What are some of the key skills and qualities that you look for in a machinery repair and maintenance supervisor?

- Technical expertise

- Management skills

- Communication skills

- Problem-solving skills

- Teamwork skills

6. What is your experience with implementing and managing a CMMS (Computerized Maintenance Management System)?

I have experience with implementing and managing CMMSs in several different organizations. I have worked with a variety of CMMS software, including SAP, Maximo, and Infor EAM. I have also developed and implemented customized CMMS solutions for specific organizational needs.

7. What are your strengths and weaknesses as a machinery repair and maintenance supervisor?

- Strengths:

- Technical expertise

- Management skills

- Communication skills

- Weaknesses:

- I am not always the most patient person.

- I can be a bit of a perfectionist.

8. What are your salary expectations for this position?

My salary expectations are commensurate with my experience and qualifications. I am confident that I can make a significant contribution to your organization and I am looking for a salary that reflects my value.

9. What are your career goals?

My career goals are to continue to grow and develop as a machinery repair and maintenance supervisor. I am passionate about my work and I am always looking for ways to improve my skills and knowledge. I believe that I can make a significant contribution to any organization and I am eager to find a new challenge.

10. Why should we hire you for this position?

I am the best candidate for this position because I have the technical expertise, management skills, and communication skills that are necessary to be successful. I am also a hard worker and I am always willing to go the extra mile. I am confident that I can make a significant contribution to your organization and I am eager to get started.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machinery Repair Maintenance Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machinery Repair Maintenance Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Machinery Repair Maintenance Supervisor plays a pivotal role in ensuring the smooth and efficient operation of machinery and equipment. Their primary responsibilities encompass:

1. Maintenance and Repair

Overseeing the maintenance and repair of all machinery, including diagnosing faults, scheduling repairs, and ensuring timely completion of maintenance tasks.

- Identifying and prioritizing repair needs based on equipment condition and performance data.

- Coordinating with maintenance technicians to schedule and execute repairs and maintenance activities.

2. Troubleshooting and Problem-Solving

Troubleshooting and resolving complex machinery issues to minimize downtime and maintain production efficiency.

- Analyzing equipment performance data to identify potential problems and develop preventative maintenance strategies.

- Conducting thorough inspections and diagnostics to determine the root causes of equipment malfunctions.

3. Team Management and Leadership

Leading and motivating a team of maintenance technicians, providing guidance and support.

- Establishing clear performance expectations, providing regular feedback, and recognizing team achievements.

- Assigning tasks, monitoring progress, and ensuring accountability for maintenance activities.

4. Budget and Resource Management

Managing the maintenance budget and ensuring the efficient use of resources.

- Forecasting maintenance costs, optimizing resource allocation, and identifying areas for process improvement.

- Negotiating with vendors and contractors to secure cost-effective maintenance services.

Interview Tips

To ace the interview for a Machinery Repair Maintenance Supervisor position, it’s essential to:

1. Research the Company and Position

Thoroughly research the company’s industry, products, and values to demonstrate your interest and fit.

- Review the job description and highlight your skills and experience that align with the requirements.

- Practice answering common interview questions related to machinery repair and maintenance.

2. Emphasize Your Technical Expertise

Quantify your technical abilities and provide specific examples of your experience in machinery repair and maintenance.

- Describe complex repairs you’ve successfully executed and the positive impact on equipment uptime.

- Share your knowledge of industry best practices and maintenance technologies.

3. Highlight Your Leadership and Management Skills

Demonstrate your ability to lead and motivate a team of maintenance technicians.

- Provide examples of how you have successfully managed teams, resolved conflicts, and fostered a positive work environment.

- Discuss your strategies for setting clear expectations, providing feedback, and recognizing team accomplishments.

4. Be Prepared to Discuss Budget and Resource Management

Show your understanding of budget and resource management principles as they relate to machinery repair and maintenance.

- Describe your experience in forecasting maintenance costs and optimizing resource utilization.

- Explain how you would negotiate with vendors and contractors to secure cost-effective maintenance services.

5. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer, demonstrating your engagement and interest in the role.

- Inquire about the company’s safety protocols and preventative maintenance practices.

- Ask about opportunities for professional development and career growth within the organization.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Machinery Repair Maintenance Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Machinery Repair Maintenance Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.