Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machining Associate interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machining Associate so you can tailor your answers to impress potential employers.

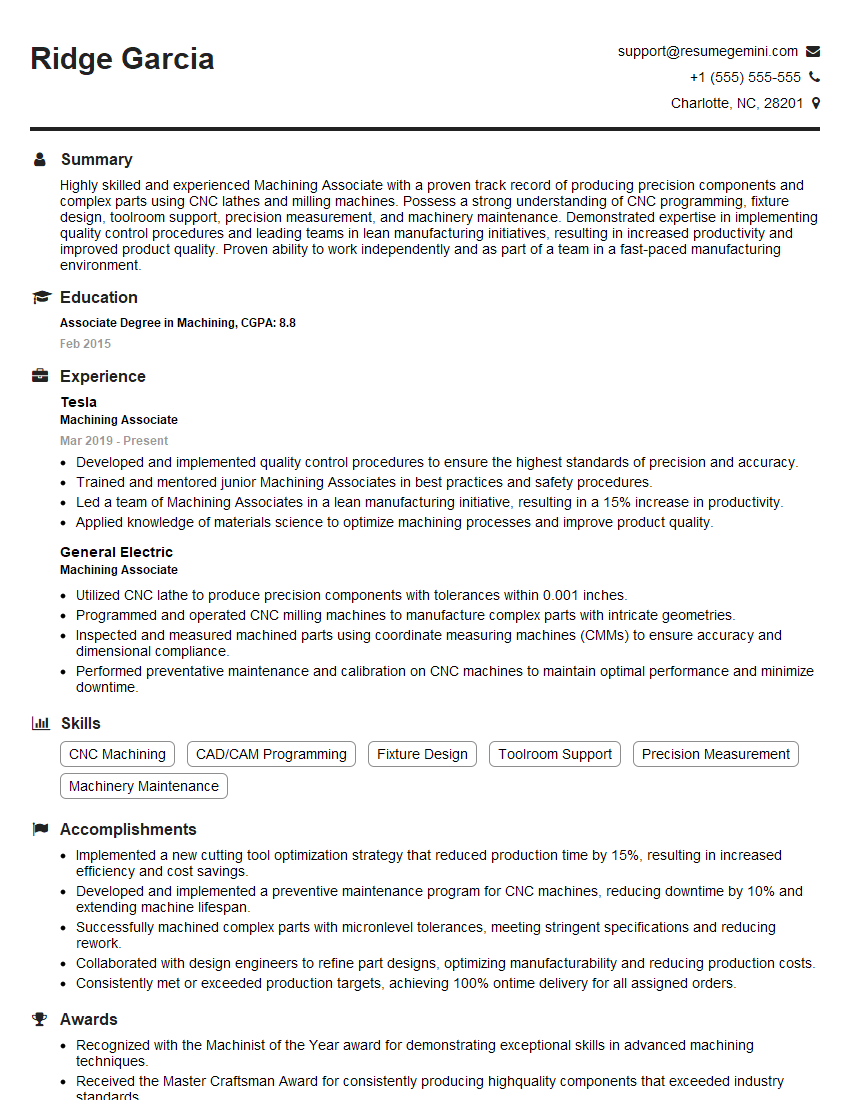

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machining Associate

1. What are the different types of machining operations you are familiar with?

- Milling

- Turning

- Drilling

- Boring

- Grinding

2. What is the difference between conventional and CNC machining?

CNC machining

- Computer Numerical Control (CNC) machining is a subtractive manufacturing process where computer-controlled machines use a variety of cutting tools to remove material from a workpiece.

- CNC machines are more precise and efficient than conventional machines, and they can produce complex parts with high accuracy and repeatability.

Conventional Machining

- Conventional machining is a subtractive manufacturing process where human operators control the machines and cutting tools.

- Conventional machines are less precise and efficient than CNC machines, and they are more likely to produce errors.

3. What are the different types of cutting tools used in machining?

- Single-point cutting tools (e.g., lathe tools, drill bits, milling cutters)

- Multi-point cutting tools (e.g., end mills, reamers, taps)

- Abrasive cutting tools (e.g., grinding wheels, honing stones)

4. What are the different types of materials that can be machined?

- Metals (e.g., steel, aluminum, titanium)

- Plastics (e.g., ABS, PVC, polyethylene)

- Composites (e.g., fiberglass, carbon fiber)

- Wood

- Glass

5. What are the different types of tolerances that can be achieved in machining?

- Dimensional tolerances

- Form tolerances

- Surface finish tolerances

6. What are the different types of quality control checks that are performed in machining?

- Visual inspection

- Dimensional measurement

- Surface finish measurement

- Hardness testing

7. What are the different types of safety precautions that must be taken when operating machining equipment?

- Wear appropriate safety gear (e.g., eye protection, gloves, hearing protection)

- Keep the work area clean and free of debris

- Be aware of the location of all emergency stops

- Never operate machining equipment while under the influence of drugs or alcohol

8. What is your experience with troubleshooting machining problems?

- Identify the problem

- Determine the root cause of the problem

- Develop a solution to the problem

- Implement the solution

- Verify that the problem has been resolved

9. What is your experience with using CAD/CAM software?

- I have experience using a variety of CAD/CAM software packages, including SolidWorks, Mastercam, and Fusion 360.

- I am proficient in using CAD/CAM software to create 3D models, generate CNC programs, and simulate machining operations.

10. Why should we hire you for this position?

- I have more than 10 years of experience as a Machining Associate.

- I am proficient in all aspects of machining, including setup, operation, and troubleshooting.

- I am a highly motivated and results-oriented individual.

- I am eager to learn new things and I am always looking for ways to improve my skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machining Associate.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machining Associate‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machining Associates are responsible for operating and maintaining various machining equipment to produce precision parts and components. They work in a manufacturing environment and collaborate with other team members to ensure efficient production processes. Key job responsibilities include:

1. Machine Operation and Maintenance

• Set up, operate, and monitor CNC machines (Computer Numerical Control) and other machining equipment.

• Interpret blueprints and technical drawings to determine machining specifications.

• Perform routine maintenance and troubleshooting on machinery to ensure optimal performance.

2. Material Handling and Inspection

• Select and load appropriate materials into machines.

• Inspect finished parts and components for dimensional accuracy, surface finish, and other quality standards.

• Identify and report any deviations from specifications to supervisors or quality control personnel.

3. Process Monitoring and Optimization

• Monitor machining processes to ensure adherence to quality standards and production schedules.

• Identify and implement process improvements to enhance efficiency and reduce waste.

• Collaborate with engineers and other team members to optimize machining parameters.

4. Safety and Compliance

• Adhere to all safety protocols and regulations in the manufacturing environment.

• Wear appropriate personal protective equipment (PPE) and maintain a clean and organized workspace.

• Follow established procedures for handling hazardous materials and waste.

Interview Tips

Preparing thoroughly for a Machining Associate interview can significantly increase your chances of success. Here are some essential tips to help you ace the interview:

1. Research the Company and Position

• Visit the company’s website and LinkedIn page to learn about their products, services, and culture.

• Thoroughly review the job description and identify the key requirements and responsibilities.

• Research the industry trends and technologies related to machining to demonstrate your up-to-date knowledge.

2. Practice and Prepare

• Practice answering common interview questions about your machining skills, experience, and qualifications.

• Prepare examples of your work that showcase your proficiency in operating and maintaining machining equipment.

• Familiarize yourself with industry acronyms and technical terms to demonstrate your expertise.

3. Dress Professionally and Arrive on Time

• Dress in professional attire that is appropriate for a manufacturing environment.

• Arrive punctually for your interview and be respectful of the interviewer’s time.

• Maintain a positive and confident demeanor throughout the interview.

4. Highlight Your Skills and Experience

• Quantify your accomplishments in your previous role by using specific metrics and results.

• Emphasize your ability to work independently and as part of a team.

• Discuss your problem-solving skills and how you have applied them in a machining environment.

5. Ask Insightful Questions

• Ask thoughtful questions about the company’s products, processes, and growth plans.

• Inquire about opportunities for professional development and career advancement within the organization.

• Show genuine interest in the role and the company by asking specific questions that demonstrate your enthusiasm.

Next Step:

Now that you’re armed with the knowledge of Machining Associate interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machining Associate positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini