Are you gearing up for an interview for a Machining Manager position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Machining Manager and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

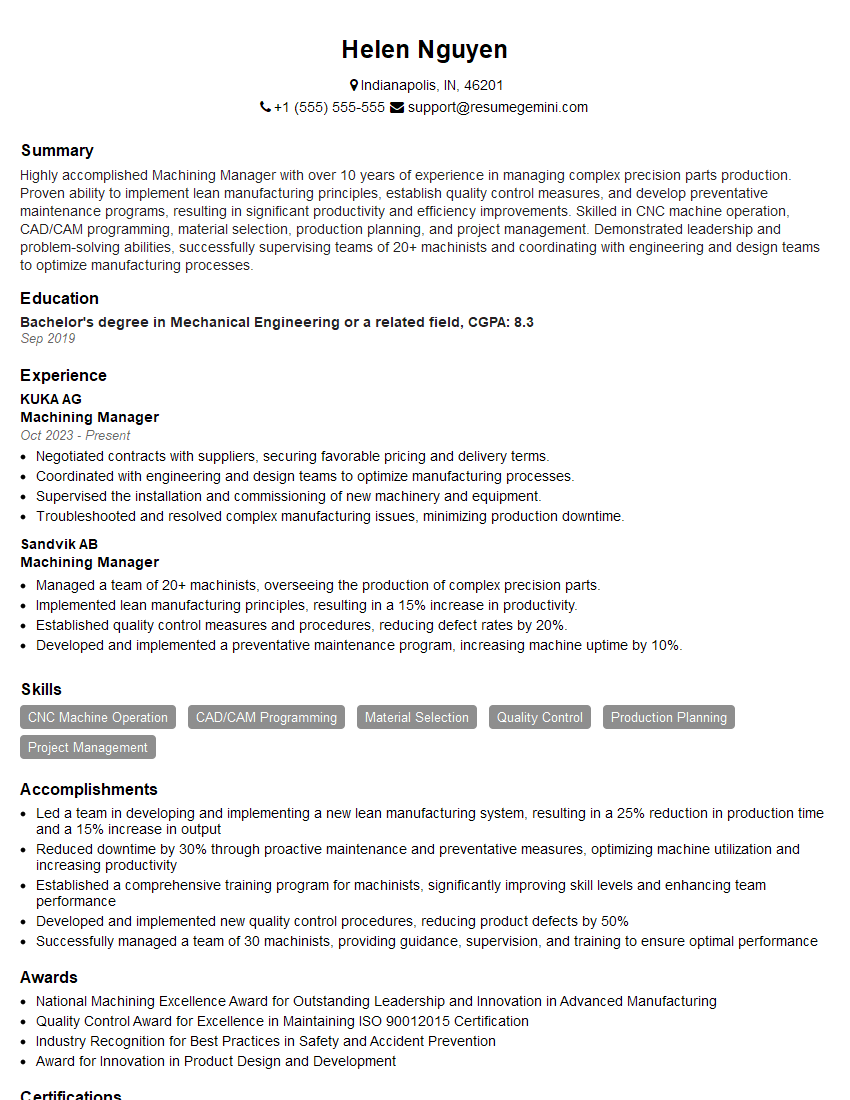

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machining Manager

1. How do you ensure the accuracy and precision of machined parts?

- Calibration and maintenance: Calibrating and maintaining machines and measuring instruments at regular intervals to ensure accuracy.

- Skill of machinist: Training and assessing machinist skills to ensure they have the expertise to operate machines precisely.

- Quality control processes: Implementing quality control processes, such as inspections and sampling, to monitor and correct any deviations from specifications.

- Temperature Control: Monitoring and controlling the temperature of the workpiece and machine to minimize thermal expansion and shrinkage.

2. Discuss the types of machining operations and their applications.

Milling

- Face milling: Flattening or resurfacing surfaces.

- End milling: Shaping edges, slots, and contours.

Turning

- External turning: Reducing the diameter or creating external threads on cylindrical workpieces.

- Internal turning: Boring holes or creating internal threads.

3. Describe the factors that influence the selection of cutting tools in machining.

- Workpiece material: Properties such as hardness, strength, and toughness.

- Machining operation: Type of operation (e.g., milling, turning) and cutting forces involved.

- Desired surface finish: Required level of smoothness or roughness.

- Tool geometry: Cutting angle, rake angle, and tool life.

4. Explain the role of coolant in machining and its benefits.

- Temperature reduction: Cools the workpiece and cutting tool, reducing heat-related damage.

- Lubrication: Minimizes friction between the tool and workpiece, extending tool life and improving surface finish.

- Chip removal: Helps flush away chips, preventing tool clogging and ensuring smooth cutting.

- Corrosion protection: Certain coolants can prevent rust and corrosion.

5. How do you optimize the machining process to improve efficiency and reduce costs?

- Machine selection: Choosing the appropriate machine for the job to maximize productivity and minimize cycle times.

- Tooling selection: Optimizing cutting tools based on factors such as material, geometry, and coating to enhance tool life and surface finish.

- Process planning: Streamlining the machining sequence to eliminate unnecessary operations and reduce setup times.

- Monitoring and control: Using sensors and software to monitor machine performance and adjust parameters in real-time to improve efficiency.

6. Discuss the importance of preventive maintenance in machining operations.

- Extended equipment lifespan: Regular maintenance helps prevent breakdowns and prolongs the life of machines.

- Improved accuracy and precision: Well-maintained machines maintain their calibration and produce consistent, accurate parts.

- Reduced downtime: Preventive maintenance identifies potential issues early, minimizing unplanned downtime and lost production.

- Increased safety: Regular inspections and maintenance ensure a safe working environment and minimize potential hazards.

7. How do you manage quality control in a machining operation?

- Inspection plans: Developing and implementing inspection plans to check parts at various stages of production.

- Measurement equipment: Using calibrated and accurate measuring instruments to ensure precise measurements.

- Non-destructive testing: Conducting non-destructive tests (e.g., ultrasonic, dye penetrant) to detect internal defects.

- Statistical process control: Monitoring and analyzing process data to identify trends and improve consistency.

8. Describe the different types of materials used in machining and their properties.

- Metals: Properties such as strength, hardness, corrosion resistance, and machinability (e.g., steel, aluminum, titanium).

- Plastics: Properties such as flexibility, resilience, and resistance to chemicals (e.g., ABS, polycarbonate, polyethylene).

- Composites: Combinations of materials with tailored properties (e.g., fiber-reinforced plastics, metal-matrix composites).

9. How do you stay updated with the latest advancements in machining technology?

- Industry conferences: Attending industry conferences and trade shows to learn about new technologies and equipment.

- Technical publications: Reading industry journals, magazines, and white papers to stay informed about innovations.

- Vendor training: Participating in training programs offered by equipment manufacturers to gain knowledge about their latest products.

- Research and development: Engaging in research and development to explore new techniques and optimize processes.

10. Describe your experience in managing a team of machinists.

- Leadership skills: Motivating and guiding team members to achieve goals and maintain productivity.

- Communication: Effectively communicating with team members, providing clear instructions, and fostering collaboration.

- Training and development: Identifying training needs and providing opportunities for team members to enhance their skills.

- Performance management: Setting performance expectations, providing feedback, and recognizing achievements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machining Manager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machining Manager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Machining Manager oversees all aspects of a machine shop. They are responsible for ensuring that the shop runs efficiently and profitably, while maintaining a high level of quality control. Key job responsibilities include:

1. Planning and Scheduling

The Machining Manager is responsible for developing and implementing the shop’s production schedule. This includes coordinating with customers to determine their needs, estimating the cost of jobs, and assigning work to the appropriate machines and operators.

- Develop and implement the shop’s production schedule

- Coordinate with customers to determine their needs

- Estimate the cost of jobs

- Assign work to the appropriate machines and operators

2. Quality Control

The Machining Manager is responsible for ensuring that all products produced by the shop meet the required quality standards. This includes developing and implementing quality control procedures, inspecting products, and taking corrective action when necessary.

- Develop and implement quality control procedures

- Inspect products

- Take corrective action when necessary

3. Machine Maintenance

The Machining Manager is responsible for maintaining the shop’s machinery. This includes scheduling maintenance, performing repairs, and troubleshooting problems.

- Schedule maintenance

- Perform repairs

- Troubleshoot problems

4. Training and Development

The Machining Manager is responsible for training and developing the shop’s employees. This includes developing training programs, conducting training sessions, and evaluating employee performance.

- Develop training programs

- Conduct training sessions

- Evaluate employee performance

Interview Tips

To ace an interview for a Machining Manager position, it is important to be prepared. Here are a few tips:

1. Research the Company

Before you go to the interview, take some time to research the company. This will help you understand the company’s culture, values, and products or services. You can find this information on the company’s website, LinkedIn page, or other online resources.

- Visit the company’s website

- Check out the company’s LinkedIn page

- Read articles about the company in the news

2. Practice Your Answers

It is also important to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview. Some common interview questions for Machining Manager positions include:

- Tell me about your experience in the machining industry.

- What are your strengths and weaknesses as a Machining Manager?

- How do you stay up-to-date on the latest machining technologies?

3. Be Professional

First impressions matter, so it is important to dress professionally and arrive on time for your interview. You should also be polite and respectful to everyone you meet, including the receptionist, the interviewer, and other employees. Make sure you bring any additional documents or items requested by the company or the hiring manager to the interview as well.

4. Ask Questions

At the end of the interview the interviewer will typically ask if you have any questions. This is your opportunity to ask questions about the position, the company, or the industry. Asking questions shows that you are interested in the position and that you are taking the interview seriously.

- What are the biggest challenges facing the company right now?

- What are the company’s goals for the next five years?

- What is the company’s culture like?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machining Manager interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.