Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machinist Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machinist Supervisor so you can tailor your answers to impress potential employers.

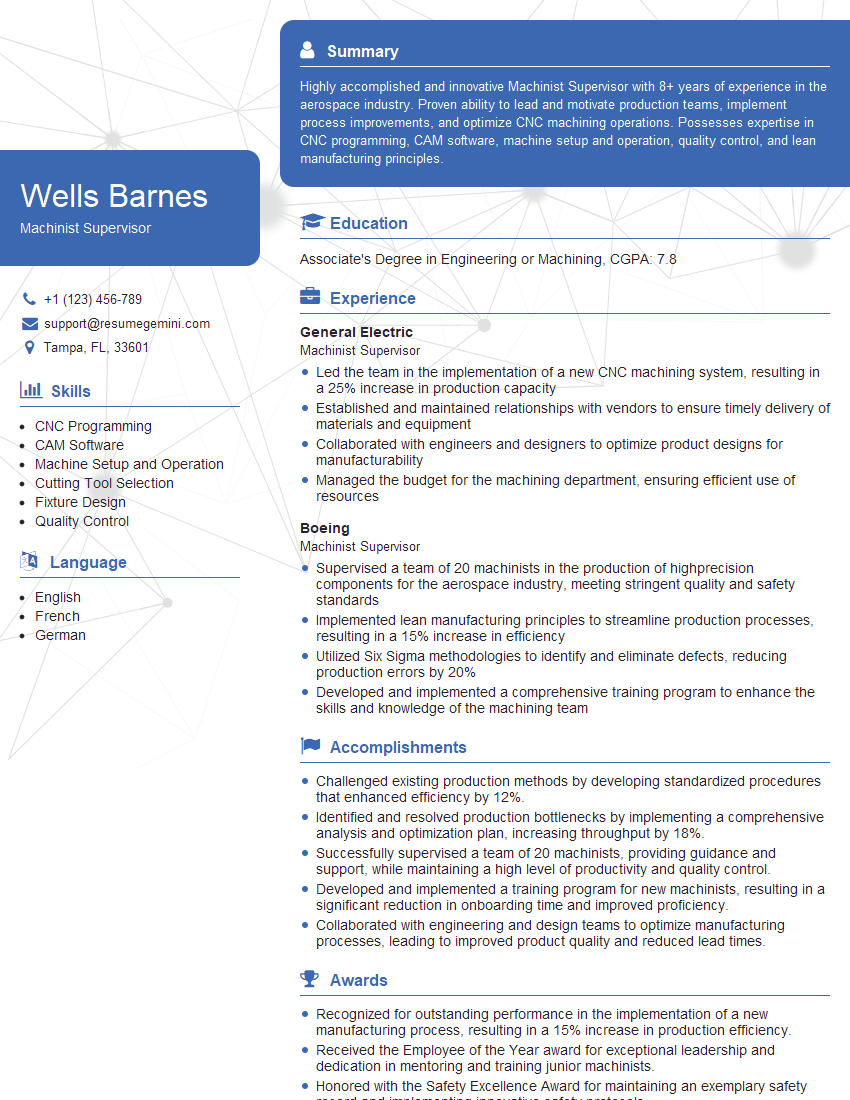

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machinist Supervisor

1. How do you ensure that the machines are properly calibrated and maintained?

As a Machinist Supervisor, I understand the critical importance of maintaining accurate and calibrated machinery. To ensure this, I implement a comprehensive maintenance program that includes the following steps:

- Regular Inspections: We perform daily, weekly, and monthly inspections to identify potential issues and address them promptly.

- Calibration Procedures: Using calibrated measuring instruments, we regularly verify the accuracy of machines and adjust them as needed.

- Preventive Maintenance: We follow established schedules for preventive maintenance tasks, such as changing filters, lubricating parts, and inspecting critical components.

- Record Keeping: We maintain detailed records of all maintenance activities, including calibration dates, replacement parts, and any adjustments made.

2. What are the key performance indicators (KPIs) you track to assess machinist performance?

Machinist Proficiency

- Cycle Time: Monitoring the time it takes machinists to complete tasks helps identify inefficiencies and opportunities for improvement.

- Scrap Rate: Tracking the percentage of rejected or defective parts produced helps assess machinist accuracy and adherence to quality standards.

- Tool Life: Monitoring tool usage and replacement frequency provides insights into machinist handling and maintenance practices.

Process Efficiency

- Machine Utilization: Measuring the percentage of time machines are in use helps identify potential bottlenecks and areas for optimization.

- Production Output: Tracking the number of parts produced per hour or shift helps assess overall productivity.

- First-Pass Yield: Calculating the percentage of parts that pass inspection on the first try indicates the accuracy and efficiency of the machining process.

3. How do you handle situations where machinists are not meeting performance expectations?

- Performance Evaluation: I conduct regular performance reviews to assess machinists’ strengths and weaknesses.

- Feedback and Coaching: I provide constructive feedback and offer guidance to help machinists improve their skills and knowledge.

- Training and Development: I identify training and development opportunities to address performance gaps and enhance machinists’ capabilities.

- Disciplinary Process: If performance issues persist despite support and guidance, I follow established disciplinary procedures to hold machinists accountable and maintain productivity.

4. Describe your approach to safety management in the machine shop.

- Hazard Identification and Risk Assessment: We conduct thorough risk assessments to identify potential hazards and implement control measures to mitigate them.

- Safety Training: All machinists receive comprehensive safety training covering proper machine operation, personal protective equipment (PPE), and emergency procedures.

- Regular Inspections: We conduct regular inspections of the work area, machinery, and PPE to ensure compliance with safety regulations.

- Safety Audits: External safety audits are conducted to assess our safety program’s effectiveness and identify areas for improvement.

5. What methods do you use to improve the efficiency of machining operations?

- Process Optimization: We analyze existing processes to identify and eliminate inefficiencies, such as reducing setup times or implementing automated solutions.

- Tooling Selection: We carefully select and optimize cutting tools to improve machining speed, accuracy, and tool life.

- Machine Scheduling: We implement efficient machine scheduling algorithms to minimize downtime and maximize utilization.

- Workforce Training: We provide training to machinists on best practices and techniques to enhance their efficiency and productivity.

6. How do you stay up-to-date on emerging technologies and advancements in the machining industry?

- Industry Events: I attend industry conferences, workshops, and trade shows to learn about the latest innovations and trends.

- Technical Publications: I subscribe to industry magazines, journals, and online resources to keep abreast of new developments.

- Networking: I engage with other professionals in the field through professional organizations and online forums to exchange knowledge and insights.

- Investment in Training: I actively participate in training programs and workshops to enhance my technical skills and stay current on industry best practices.

7. How do you manage the inventory of raw materials and finished products?

- Inventory Control System: We use an inventory control system to track raw materials and finished products in real-time.

- Just-in-Time Inventory: We implement just-in-time inventory practices to minimize waste and reduce storage costs.

- Supplier Management: We maintain strong relationships with suppliers to ensure timely delivery and quality of materials.

- Production Planning: We coordinate with the production team to align inventory levels with production schedules and customer demand.

8. What is your experience with implementing continuous improvement programs in a machining environment?

In my previous role, I led a successful continuous improvement program that resulted in significant efficiency gains and cost reductions. I employed the following strategies:

- Process Mapping: We created detailed process maps to identify areas for improvement and optimize workflows.

- Data Analysis: We collected and analyzed data to identify bottlenecks, inefficiencies, and waste.

- Kaizen Events: We conducted Kaizen events, involving cross-functional teams to brainstorm and implement improvements.

- Employee Engagement: We encouraged employee participation and empowered them to suggest and implement improvements.

9. How do you ensure that quality standards are consistently met in the production process?

- Quality Control Plan: We have established a comprehensive quality control plan that defines acceptance criteria and inspection procedures.

- Statistical Process Control: We use statistical process control (SPC) techniques to monitor and adjust processes to prevent defects.

- Quality Inspections: We conduct thorough inspections at various stages of the production process to identify and rectify any non-conformances.

- Customer Feedback: We actively seek customer feedback and use it to improve our quality processes and products.

10. What is your approach to team leadership and development as a Machinist Supervisor?

- Empowerment: I empower my team by providing them with the authority and resources to make decisions and solve problems.

- Communication: I foster open communication, encourage feedback, and listen to my team’s ideas and concerns.

- Recognition: I recognize and reward team members for their hard work and contributions to the team’s success.

- Mentoring and Training: I invest in the development of my team by providing mentoring and training opportunities to enhance their skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machinist Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machinist Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Machinist Supervisor is responsible for the overall operation and supervision of the machine shop, including planning, organizing, and directing the activities of the machinists and other staff.

1. Production Management

Ensuring that production targets are met by overseeing the production process, monitoring progress, and making adjustments as necessary.

- Scheduling and assigning tasks to machinists based on their skills and availability.

- Coordinating with the production team to ensure a smooth and efficient workflow.

2. Quality Control

Ensuring that the products meet the required quality standards by conducting regular inspections and implementing quality control measures.

- Developing and implementing quality control procedures and standards.

- Conducting regular product inspections to ensure compliance with specifications.

3. Team Management

Leading and motivating a team of machinists, providing support and guidance, and ensuring a positive and productive work environment.

- Providing training and development opportunities to enhance the skills of the machinists.

- Managing employee performance and providing feedback to improve productivity and quality.

4. Safety Management

Maintaining a safe and healthy work environment by ensuring compliance with safety regulations and implementing safety protocols.

- Conducting regular safety inspections and identifying potential hazards.

- Developing and implementing safety protocols and procedures.

Interview Tips

Preparing for an interview for the position of Machinist Supervisor requires a combination of technical knowledge, leadership skills, and interpersonal abilities. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Thoroughly research the company’s background, industry, and specific role you are applying for. This demonstrates your interest and enthusiasm for the position.

- Visit the company’s website and social media pages to gather information about their culture, values, and recent developments.

- Read industry publications and news articles to stay updated on the latest trends and technologies relevant to the role.

2. Highlight Your Skills and Experience

Tailor your resume and cover letter to emphasize the skills and experience that are most relevant to the job requirements. Use specific examples to demonstrate your abilities, such as:

- Describe a situation where you successfully managed a team of machinists, motivating them to achieve production targets while maintaining high quality standards.

- Provide an example of how you improved production efficiency by implementing a new process or technology.

3. Be Prepared to Discuss Safety

Safety is a critical aspect of Machinist Supervisor roles. Be prepared to discuss your understanding of safety regulations, your experience in implementing safety protocols, and your commitment to maintaining a safe work environment.

- Explain how you would conduct a safety inspection and identify potential hazards in a machine shop.

- Describe a situation where you successfully resolved a safety issue and prevented an accident.

4. Practice Your Interview Answers

Practice answering common interview questions to improve your confidence and delivery. Prepare responses that are concise, clear, and highlight your strengths. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Practice answering questions about your leadership style, team management skills, and experience in quality control.

- Prepare for questions about your knowledge of machining processes, safety regulations, and industry best practices.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. Maintain good posture and make eye contact with the interviewer to convey confidence and respect.

- Consider wearing a suit or business casual attire.

- Arrive at the interview location at least 15 minutes early to avoid any delays.

Next Step:

Now that you’re armed with the knowledge of Machinist Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machinist Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini