Are you gearing up for an interview for a Magnaflux Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Magnaflux Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

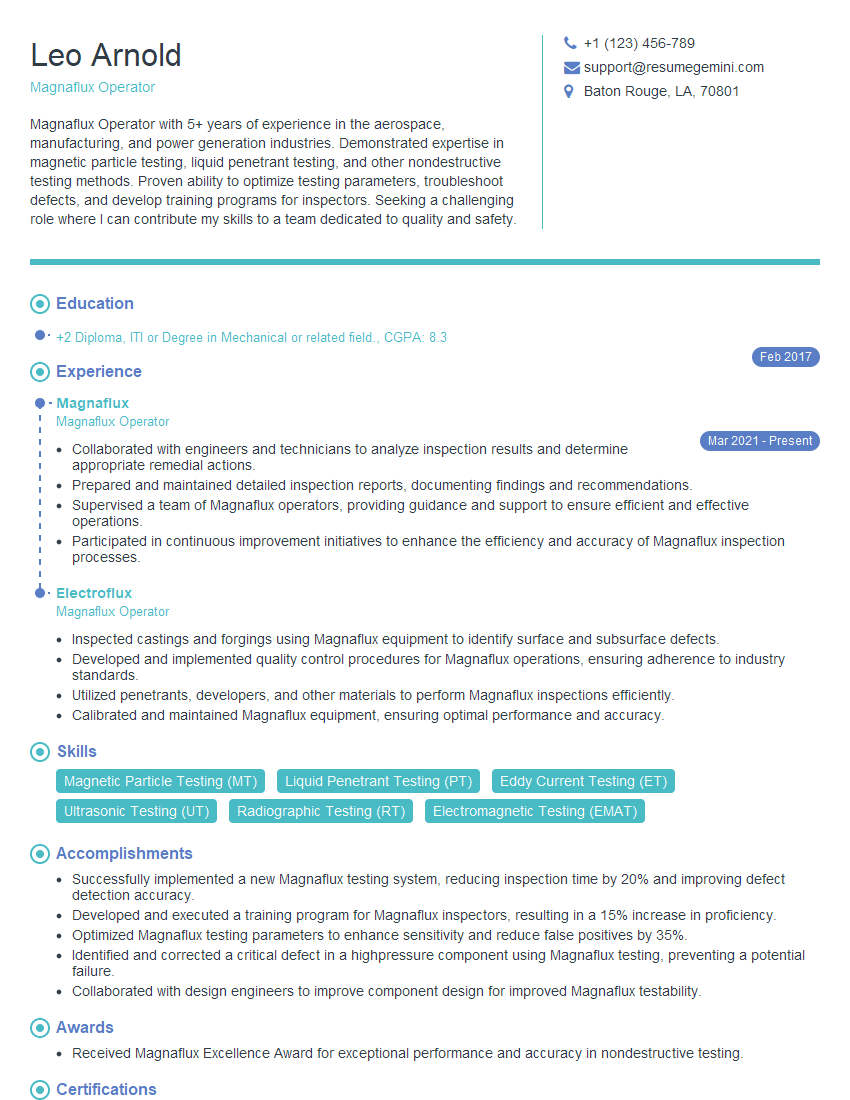

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Magnaflux Operator

1. What is the basic principle of magnetic particle inspection?

The basic principle of magnetic particle inspection is to induce a magnetic field in the test object and then apply magnetic particles to the surface. If there are any defects or discontinuities in the material, the magnetic particles will be attracted to them, making them visible.

2. What are the different types of magnetic particle inspection methods?

There are two main types of magnetic particle inspection methods: wet method and dry method.

Wet method

- In the wet method, the magnetic particles are suspended in a liquid, typically water or oil.

- The liquid is applied to the surface of the test object, and the magnetic field is induced.

- The magnetic particles are then attracted to any defects or discontinuities in the material, and they can be seen as dark spots on the surface.

Dry method

- In the dry method, the magnetic particles are applied to the surface of the test object in powder form.

- The magnetic field is then induced, and the magnetic particles are attracted to any defects or discontinuities in the material.

- The magnetic particles can be seen as dark spots on the surface, or they can be collected and analyzed under a microscope.

3. What are the advantages and disadvantages of wet and dry magnetic particle inspection methods?

The wet method is more sensitive than the dry method, but it is also more time-consuming and requires more cleanup.

The dry method is less sensitive than the wet method, but it is faster and less messy.

4. What are the different types of defects that can be detected using magnetic particle inspection?

Magnetic particle inspection can be used to detect a variety of defects, including:

- Surface cracks

- Subsurface cracks

- Inclusions

- Voids

- Welding defects

5. What are the factors that affect the sensitivity of magnetic particle inspection?

The sensitivity of magnetic particle inspection is affected by a number of factors, including:

- The strength of the magnetic field

- The type of magnetic particles used

- The surface condition of the test object

- The presence of any contaminants

6. What are the safety precautions that must be taken when performing magnetic particle inspection?

When performing magnetic particle inspection, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a lab coat.

- Ensure that the test object is properly grounded.

- Do not use magnetic particle inspection on objects that are made of or contain flammable materials.

- Be aware of the potential for electrical hazards.

- Follow all manufacturer’s instructions for the equipment being used.

7. What are the different codes and standards that apply to magnetic particle inspection?

There are a number of codes and standards that apply to magnetic particle inspection, including:

- ASTM E1444 – Standard Practice for Magnetic Particle Examination

- ISO 9934 – Non-destructive testing – Magnetic particle testing

- AWS D1.1 – Structural Welding Code – Steel

- ASME Boiler and Pressure Vessel Code

8. What are the career opportunities for Magnaflux Operators?

Magnaflux Operators can work in a variety of industries, including manufacturing, construction, and oil and gas. They can also work as independent contractors. With experience, Magnaflux Operators can advance to positions such as Quality Control Inspector or Nondestructive Testing Supervisor.

9. What are the skills and qualifications required to be a successful Magnaflux Operator?

To be a successful Magnaflux Operator, you will need to have the following skills and qualifications:

- A strong understanding of the principles of magnetic particle inspection

- Experience in operating magnetic particle inspection equipment

- Knowledge of the different codes and standards that apply to magnetic particle inspection

- Excellent attention to detail

- Good communication and interpersonal skills

10. Why are you interested in this position?

I am interested in this position because I am a highly skilled and experienced Magnaflux Operator with a strong understanding of the principles and practices of magnetic particle inspection. I am also passionate about quality control and ensuring that products meet the highest standards of safety and reliability.

I am confident that I have the skills and qualifications necessary to be successful in this role and I am eager to contribute my expertise to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Magnaflux Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Magnaflux Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Magnaflux Operators perform a variety of tasks related to the nondestructive testing (NDT) of metal components and structures using the magnaflux method. Key responsibilities include:

1. Test Material Preparation

Preparing materials for testing by cleaning and demagnetizing surfaces, applying penetrants, and developing inspections.

2. Equipment Handling

Operating and maintaining magnaflux equipment, including power units, magnetizing yokes, and testing coils.

3. Test Execution

Performing magnaflux testing according to established procedures, including magnetizing, applying penetrant, developing, and evaluating results.

4. Inspection and Reporting

Inspecting test results for indications of cracks, defects, or other flaws; preparing and submitting reports.

5. Data Analysis

Analyzing test results, interpreting data, and providing recommendations based on findings.

6. Maintenance and Calibration

Performing maintenance and calibration on magnaflux equipment to ensure accuracy and reliability.

7. Safety Compliance

Adhering to all safety protocols and regulations related to NDT testing.

Interview Tips

To ace an interview for a Magnaflux Operator position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and specific requirements for the Magnaflux Operator role.

2. Highlight Relevant Experience and Skills

Emphasize your experience with NDT testing, particularly in the magnaflux method.

Example: “In my previous role, I conducted over 1,000 magnaflux tests on critical aircraft components, consistently meeting accuracy and safety standards.”

3. Demonstrate Understanding of Magnaflux Processes

Explain the principles and procedures involved in magnaflux testing, including surface preparation, equipment operation, and result interpretation.

Example: “I understand the importance of thorough surface preparation to ensure accurate test results. I follow strict protocols for magnetization, penetrant application, and development to maximize defect detection.”

4. Showcase Safety Consciousness

Stress your commitment to safety by highlighting your adherence to NDT safety protocols.

Example: “Safety is paramount in NDT. I always wear appropriate PPE, ensure proper equipment calibration, and follow established safety guidelines.”

5. Emphasize Attention to Detail

Magnaflux testing requires meticulous attention to detail. Highlight your ability to identify and interpret even subtle indications of flaws.

Example: “My keen eye and systematic approach allow me to detect defects that others might miss, ensuring the integrity of inspected components.”

6. Practice Common Interview Questions

Prepare for common interview questions such as “Tell me about your experience with magnaflux testing” or “How do you prioritize safety in your work?”

7. Ask Thoughtful Questions

Demonstrate your interest and enthusiasm by asking informed questions about the company’s NDT practices or the specific role requirements.

8. Follow Up

After the interview, send a thank-you note to the interviewer, reiterating your interest and key qualifications.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Magnaflux Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Magnaflux Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.