Feeling lost in a sea of interview questions? Landed that dream interview for Magnet Valve Assembler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Magnet Valve Assembler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

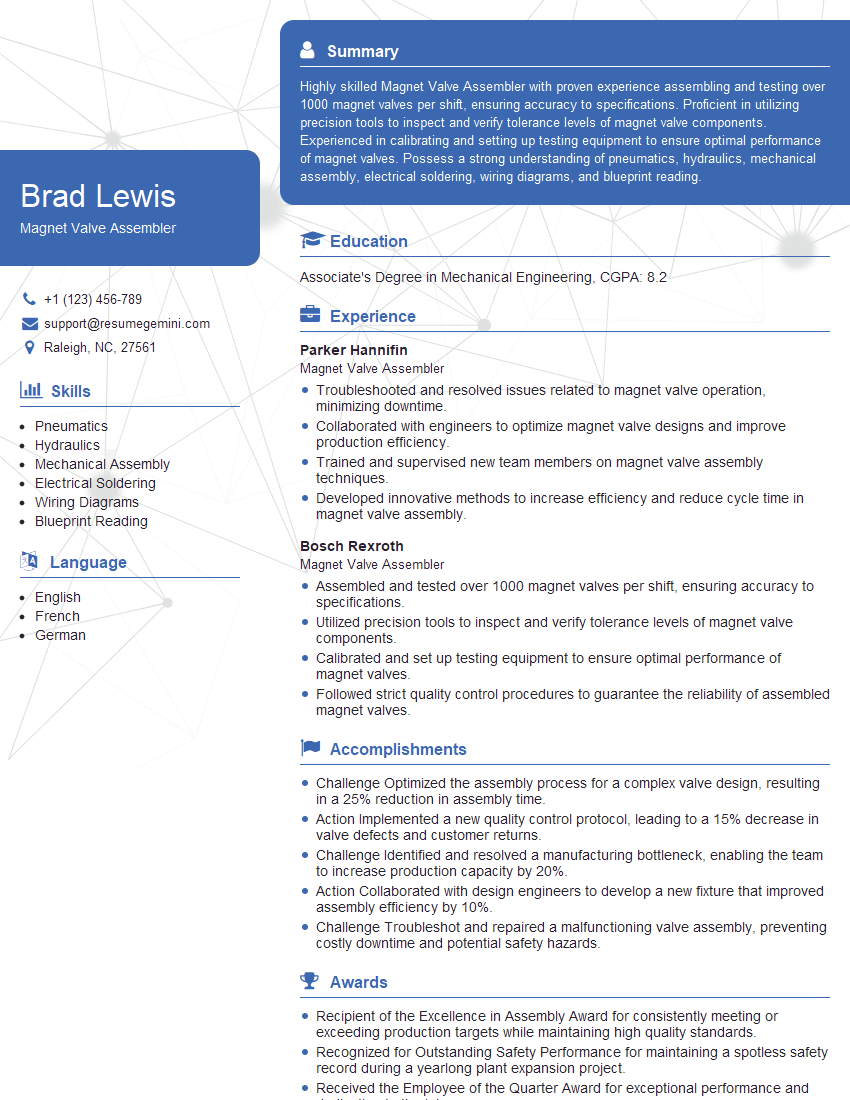

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Magnet Valve Assembler

1. Describe the process of assembling a magnet valve.

- Gathering necessary components and materials

- Inspecting components for defects

- Lubricating components as required

- Assembling valve body, spool, and coil

- Testing valve for proper function

2. What are the different types of magnet valves and their applications?

Solenoid valves

- Use an electromagnetic coil to open or close a valve

- Applications: industrial automation, fluid control, medical devices

Pilot-operated valves

- Use a smaller valve (pilot valve) to control a larger valve (main valve)

- Applications: high-pressure systems, where direct solenoid operation may not be sufficient

Direct-acting valves

- Use the force of the coil directly to open or close the valve

- Applications: low-pressure systems, where rapid response is required

3. How do you troubleshoot a magnet valve that is not functioning properly?

- Check for power supply and proper voltage

- Inspect coil for damage or overheating

- Examine valve body and spool for wear or contamination

- Measure resistance across coil to check for continuity

- Perform functional tests to identify the source of the problem

4. What are the safety precautions that must be taken when working with magnet valves?

- Wear proper personal protective equipment (PPE)

- Ensure safe handling and storage of valves

- Follow electrical safety guidelines when dealing with electrical components

- Avoid contact with moving parts or high-pressure fluids

- Refer to manufacturer’s instructions for proper operation and maintenance

5. How do you maintain and calibrate magnet valves to ensure optimal performance?

- Regularly clean and inspect valves

- Lubricate moving parts as recommended

- Perform functional tests to verify proper operation

- Calibrate valves to ensure they meet required specifications

- Keep records of maintenance and calibration activities

6. What are the industry standards and regulations that apply to the assembly and testing of magnet valves?

- ISO 9001: Quality management system

- IEC 60529: Degrees of protection provided by enclosures

- UL 508: Standard for safety of power transformers

- CSA C22.2 No. 14: Safety standard for industrial control equipment

- Specific industry regulations may also apply depending on the application

7. How do you stay updated with the latest technologies and advancements in the field of magnet valve assembly?

- Attend industry conferences and exhibitions

- Read technical publications and white papers

- Enroll in training courses and workshops

- Network with professionals in the field

- Collaborate with valve manufacturers and suppliers

8. Describe a challenging project you worked on related to magnet valve assembly and how you overcame the challenges.

- Challenge: Assembling a complex multi-stage magnet valve

- Solution: Developed a customized assembly process, used precision tools

- Challenge: Valve not meeting performance specifications

- Solution: Identified and corrected alignment issues, adjusted calibration settings

9. How do you manage quality control and ensure that magnet valves meet customer requirements?

- Follow strict assembly and testing procedures

- Perform thorough inspections at every stage of assembly

- Use specialized testing equipment to verify functionality

- Document all quality control activities

- Collaborate with quality assurance team to ensure compliance

10. What are your strengths and weaknesses as a Magnet Valve Assembler?

Strengths:

- Proficient in all aspects of magnet valve assembly

- Excellent attention to detail and quality-focused

- Strong troubleshooting and problem-solving skills

- Ability to work independently and as part of a team

Weaknesses:

- Limited experience with certain valve designs

- Sometimes overlook minor details during inspection

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Magnet Valve Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Magnet Valve Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Magnet Valve Assemblers play a pivotal role in the manufacturing industry, deftly assembling and testing a wide range of valves used in diverse applications. Their core responsibilities encompass the following:

1. Component Preparation

Ensuring accurate preparation of all the requisite components, meticulously checking their compliance with established quality standards.

- Inspect coils, housings, plungers, and gaskets for any defects or deviations.

- Verify component compatibility and proper fit before assembly.

2. Assembly Process Execution

Executing the assembly process with precision and attention to detail, adhering to predefined specifications and standard operating procedures.

- Assemble valves by aligning and connecting components, ensuring proper positioning and orientation.

- Secure components using appropriate techniques, such as soldering, crimping, or welding.

3. Functional Testing and Inspection

Rigorously testing assembled valves to verify their functionality and adherence to quality parameters.

- Conduct electrical continuity tests to ensure proper electrical connections.

- Perform pressure integrity tests to ascertain leak-proof performance.

4. Quality Assurance Maintenance

Upholding high-quality standards by meticulously inspecting assembled valves, identifying and rectifying any discrepancies.

- Review assembly records, test results, and inspection reports.

- Proactively identify areas for process improvement, enhancing overall production efficiency.

Interview Tips

Preparing for a Magnet Valve Assembler interview requires a holistic approach, encompassing technical proficiency, attention to detail, and a commitment to quality. Here are some invaluable tips to help you ace your interview:

1. Technical Expertise Showcase

Demonstrate your comprehensive understanding of magnet valve assembly principles and techniques. Emphasize your proficiency in component identification, assembly procedures, and functional testing.

- Describe your previous experience in assembling and testing similar valves, quantifying your contributions and accomplishments.

- Highlight your knowledge of industry standards and quality control measures, showcasing your commitment to precision and reliability.

2. Communication and Teamwork

Effective communication and teamwork are vital in a manufacturing environment. Highlight your ability to work harmoniously with colleagues, interpret technical instructions, and convey information clearly.

- Provide examples of your successful collaboration on assembly projects, explaining how you contributed to problem-solving and decision-making.

- Emphasize your ability to follow verbal and written instructions with accuracy, ensuring proper execution of assembly tasks.

3. Quality Orientation

Quality is paramount in the manufacturing industry. Showcase your unwavering commitment to quality by highlighting your attention to detail, meticulous inspection techniques, and proactive approach to defect prevention.

- Explain your understanding of quality control processes and your role in ensuring product integrity.

- Share examples of your successful implementation of quality improvement initiatives, demonstrating your drive for continuous improvement.

4. Continuous Learning and Improvement

The manufacturing industry is constantly evolving. Express your eagerness to stay abreast of technological advancements and industry best practices.

- Describe your proactive approach to professional development, such as attending training programs or pursuing industry certifications.

- Explain how you leverage industry resources and publications to expand your knowledge and enhance your skills.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Magnet Valve Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.