Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Magnetic Grinder Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

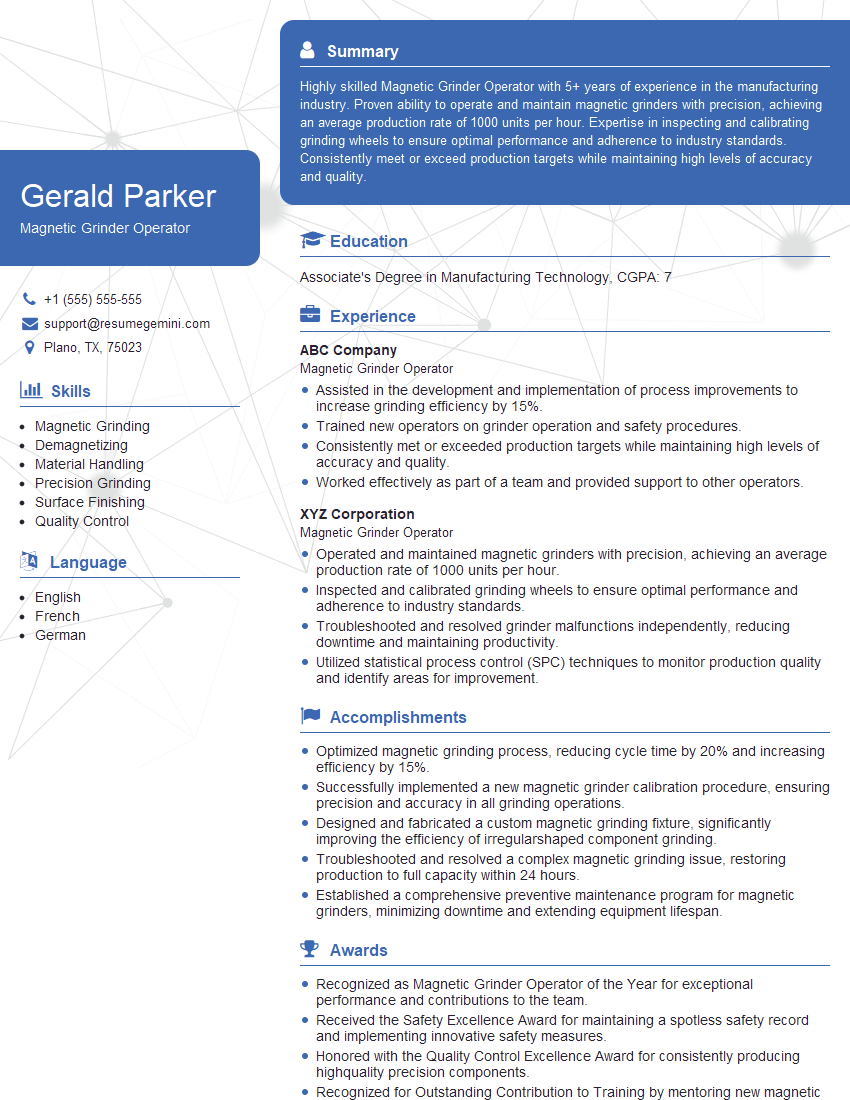

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Magnetic Grinder Operator

1. Can you elaborate on the process of setting up and calibrating a magnetic grinder?

- First, I ensure that the workpiece is correctly secured on the magnetic chuck.

- Next, I calibrate the grinder using a test piece to determine the optimal grinding parameters for the specific material and desired finish.

- I adjust the grinding wheel’s speed, feed rate, and other settings based on the calibration results.

2. Describe the safety precautions you follow when operating a magnetic grinder.

Personal Protective Equipment (PPE)

- Wear safety glasses, earplugs, and gloves to protect against flying debris and noise.

Grinder Operation

- Ensure that the grinder is properly grounded to prevent electrical hazards.

- Keep the work area clean and free of obstructions to prevent accidents.

- Never operate the grinder without proper training and supervision.

3. How do you troubleshoot common issues that arise during magnetic grinding?

- If the workpiece is not being ground evenly, I check the alignment of the grinding wheel and make adjustments as necessary.

- Excessive vibration during grinding may indicate an unbalanced grinding wheel or a loose chuck. I address these issues accordingly.

- If the grinder is producing excessive sparks, I check the grinding wheel for wear or damage and replace it if needed.

4. What types of grinding wheels are commonly used in magnetic grinders, and how do you select the appropriate one?

- Aluminum Oxide: General-purpose wheels for ferrous and non-ferrous metals

- Silicon Carbide: Abrasive wheels for hard materials like ceramics and glass

- Diamond: Highly durable wheels for precision grinding

- I consider factors such as the workpiece material, desired surface finish, and grinding conditions to select the most suitable grinding wheel.

5. How do you maintain and clean a magnetic grinder to ensure optimal performance?

- Regularly clean the grinding wheel and chuck to remove debris.

- Inspect the electrical components and wiring for damage or wear.

- Lubricate moving parts according to the manufacturer’s recommendations.

- Follow proper storage procedures to prevent rust and damage when not in use.

6. Describe the different types of surfaces that can be achieved using a magnetic grinder.

- Flat grinding: Producing flat and even surfaces

- Cylindrical grinding: Grinding cylindrical workpieces

- Surface grinding: Grinding complex shapes and contours

- Offhand grinding: Freehand grinding for irregular surfaces

7. How do you handle and store magnetic grinding wheels safely?

- Always use proper handling equipment to avoid damage or injury.

- Store grinding wheels in a dry and secure location to prevent moisture absorption.

- Inspect grinding wheels before each use for cracks or damage. Never use a damaged grinding wheel.

8. What is the significance of coolant in magnetic grinding?

- Cools the workpiece and grinding wheel, preventing overheating.

- Removes grinding swarf and debris, maintaining a clean grinding environment.

- Lubricates the grinding process, reducing friction and wear.

9. How do you monitor and control the temperature of the workpiece during magnetic grinding?

- Use temperature sensors or infrared thermometers to monitor workpiece temperature.

- Adjust grinding parameters such as wheel speed, feed rate, and coolant flow to control temperature.

- Take regular breaks to allow the workpiece to cool down and prevent thermal damage.

10. What are the key performance indicators (KPIs) you would track to assess the effectiveness of magnetic grinding operations?

- Surface finish: Measured using surface roughness testers

- Material removal rate: Calculated based on the workpiece weight before and after grinding

- Cycle time: Time taken to complete a grinding operation

- Wheel life: Number of workpieces ground before the grinding wheel needs replacing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Magnetic Grinder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Magnetic Grinder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Magnetic Grinder Operator is responsible for setting up, operating, and maintaining the magnetic grinder system. This includes preparing the grinding stones, loading and unloading materials, and ensuring the quality of the finished product. The operator must be able to identify and resolve any problems that occur during the grinding process, and must follow all safety procedures.

1. Preparation

The operator is responsible for preparing the grinding stones by dressing them to the correct profile. This is done using a diamond-tipped dressing tool.

- Load the grinding stones into the grinder.

- Adjust the grinding stones to the correct height and angle.

- Set the grinding speed and feed rate.

- Load the material to be ground into the grinder.

2. Operation

Once the grinder is set up, the operator starts the grinding process. The operator must monitor the grinding process to ensure that the material is being ground to the correct size and finish.

- Monitor the grinding process and make adjustments as needed.

- Unload the finished product from the grinder.

- Clean and maintain the grinder.

3. Quality Control

The operator is responsible for ensuring the quality of the finished product. This includes checking the size and finish of the product, and identifying any defects.

- Inspect the finished product for size and finish.

- Identify any defects in the finished product.

- Reject any finished product that does not meet specifications.

4. Safety

The operator must follow all safety procedures when operating the magnetic grinder. This includes wearing the proper personal protective equipment (PPE), and following the lockout/tagout procedures.

- Wear the proper PPE, including safety glasses, earplugs, and gloves.

- Follow the lockout/tagout procedures when servicing the grinder.

- Keep the work area clean and free of debris.

Interview Tips

To ace the interview for a Magnetic Grinder Operator position, it is important to prepare for the following:

1. Technical Questions

The interviewer will likely ask you questions about your experience with magnetic grinders, as well as your knowledge of the grinding process.

- Describe your experience with magnetic grinders.

- Explain the grinding process.

- Discuss the different types of grinding stones and their applications.

- Describe the safety procedures for operating a magnetic grinder.

2. Behavioral Questions

The interviewer will also ask you behavioral questions to assess your skills and abilities.

- Tell me about a time when you had to troubleshoot a problem with a magnetic grinder.

- Describe a time when you had to work effectively as part of a team.

- Give me an example of a time when you had to deal with a difficult customer or coworker.

3. Preparation

To prepare for your interview, it is important to do your research and practice answering common interview questions.

- Research the company and the position.

- Practice answering common interview questions.

- Dress professionally and arrive on time for your interview.

4. Enthusiasm and Confidence

It is important to show the interviewer that you are enthusiastic about the position and that you are confident in your abilities.

- Be enthusiastic about the position and the company.

- Be confident in your abilities and experience.

- Ask questions about the position and the company.

- Thank the interviewer for their time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Magnetic Grinder Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Magnetic Grinder Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.