Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Magnetic Particle and Penetrant Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

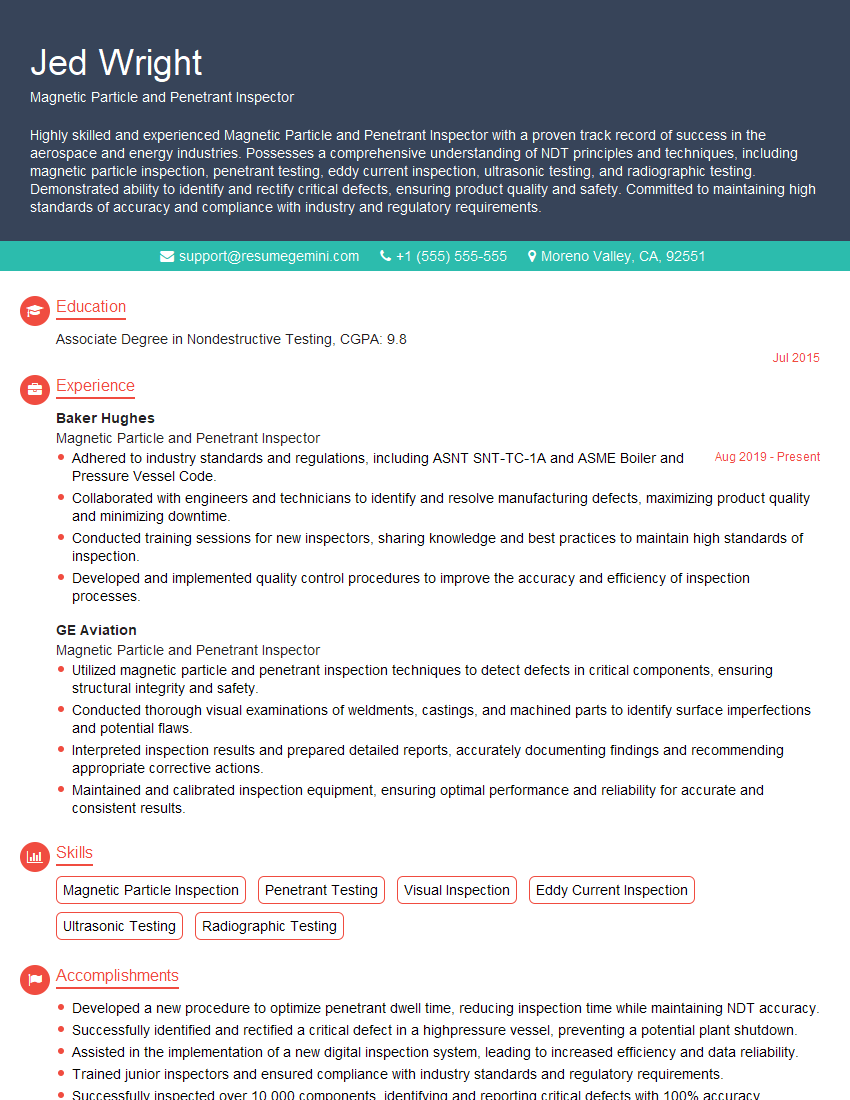

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Magnetic Particle and Penetrant Inspector

1. Explain the difference between magnetic particle inspection (MPI) and penetrant testing (PT)?

- MPI is a non-destructive testing (NDT) method that uses magnetic particles to detect surface and near-surface discontinuities in ferromagnetic materials.

- PT is an NDT method that uses a liquid penetrant to detect surface-breaking discontinuities in any material

2. What are the advantages of using MPI and PT over other NDT methods?

Advantages of MPI:

- High sensitivity to surface and near-surface discontinuities

- Relatively low cost

- Portable and easy to use

Advantages of PT:

- Can detect surface-breaking discontinuities in any material

- Relatively low cost

- Portable and easy to use

3. What are the limitations of using MPI and PT?

Limitations of MPI:

- Cannot be used on non-ferromagnetic materials

- May not be able to detect all types of discontinuities

Limitations of PT:

- Cannot detect subsurface discontinuities

- May not be able to detect all types of discontinuities

4. What are the different types of magnetic particles used in MPI?

- Carbonyl iron

- Magnetite

- Nickel

5. What are the different types of penetrants used in PT?

Fluorescent Penetrants:

- Visible under ultraviolet light

- Typically used for critical applications

Non-Fluorescent Penetrants:

- Visible under white light

- Typically used for less critical applications

Water-Washable Penetrants:

- Can be removed with water

- Typically used for applications where post-inspection cleaning is required

Solvent-Removable Penetrants:

- Must be removed with a solvent

- Typically used for applications where post-inspection cleaning is not required

6. What are the different steps involved in MPI?

- Surface preparation

- Magnetization

- Application of magnetic particles

- Inspection

- Demagnetization

7. What are the different steps involved in PT?

- Surface preparation

- Application of penetrant

- Dwell time

- Removal of excess penetrant

- Application of developer

- Inspection

8. What are the safety precautions that should be taken when using MPI and PT?

MPI:

- Wear appropriate personal protective equipment (PPE)

- Use magnetic particle equipment in a well-ventilated area

- Do not use magnetic particle equipment near flammable materials

PT:

- Wear appropriate PPE

- Use penetrant testing equipment in a well-ventilated area

- Do not use penetrant testing equipment near flammable materials

- Do not ingest or inhale penetrants

9. What are the industry standards that apply to MPI and PT?

MPI:

- ASTM E1444

- ISO 9934

PT:

- ASTM E165

- ISO 3452

10. What are the career opportunities for Magnetic Particle and Penetrant Inspectors?

- NDT Inspector

- Quality Control Inspector

- Materials Engineer

- NDE Technician

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Magnetic Particle and Penetrant Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Magnetic Particle and Penetrant Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Magnetic Particle and Penetrant Inspectors are responsible for ensuring the integrity of metal components and structures, mainly through non-destructive testing methods, to detect surface and subsurface defects. Here are some key job responsibilities for this role:

1. Performing Magnetic Particle Inspection (MPI)

Conduct MPI to detect surface and subsurface cracks, defects, and discontinuities in ferromagnetic materials. This involves applying magnetic fields and magnetic particles to magnetize the materials and reveal any imperfections.

- Preparing the test surface by cleaning and demagnetizing

- Applying appropriate magnetic fields using coils or magnets

- Selecting and applying magnetic particles to enhance detection

- Identifying, interpreting, and documenting any indications found

2. Conducting Penetrant Inspection (PT)

Perform PT to detect surface-breaking defects in non-ferromagnetic or non-conductive materials. This involves applying penetrant liquids to penetrate defects and using developers to draw out the penetrant, making defects visible.

- Selecting and applying appropriate penetrant materials

- Controlling the penetration and development time

- Removing excess penetrant and applying developers

- Examining the surface for indications and evaluating their severity

3. Interpreting and Reporting Results

Inspectors analyze and interpret the results of MPI and PT tests, identifying and evaluating any indications. They document the findings in inspection reports that provide details of the test methods used, any defects detected, and recommendations for further action.

4. Maintaining Equipment and Calibrating Standards

Inspectors ensure that the MPI and PT equipment is properly maintained, calibrated, and ready for use. This includes regular calibration checks and maintenance tasks to ensure accurate and reliable testing.

Interview Tips

Preparing for an interview as a Magnetic Particle and Penetrant Inspector requires a combination of technical knowledge and communication skills. Here are some tips to help you ace your interview:

1. Know the Industry and Standards

Research the industry standards related to MPI and PT, including ASTM, ISO, and ASME codes. Understanding these standards and their application demonstrates your commitment to quality and adherence to best practices.

- Familiarize yourself with the different non-destructive testing methods used.

- Stay updated with the latest technological advancements in MPI and PT.

2. Highlight Your Experience and Skills

Emphasize your experience in conducting MPI and PT inspections, including the types of materials and components you have inspected. Highlight your ability to interpret and report test results accurately.

- Quantify your accomplishments with specific examples and metrics.

- Demonstrate your skills in identifying and evaluating defects.

3. Prepare for Technical Questions

Expect technical questions related to MPI and PT, such as the principles behind each method, typical defects detected, and the limitations of each technique. Be prepared to explain your understanding clearly and provide examples.

- Review the principles of magnetism and magnetic field induction.

- Study the different types of penetrants and their applications.

4. Show Your Commitment to Safety

MPI and PT inspections involve working with hazardous materials and equipment. Emphasize your commitment to safety and compliance with all applicable regulations and industry best practices.

- Highlight your knowledge of Material Safety Data Sheets (MSDSs).

- Demonstrate your adherence to proper handling and disposal of hazardous materials.

Next Step:

Now that you’re armed with the knowledge of Magnetic Particle and Penetrant Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Magnetic Particle and Penetrant Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini