Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Magnetic Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

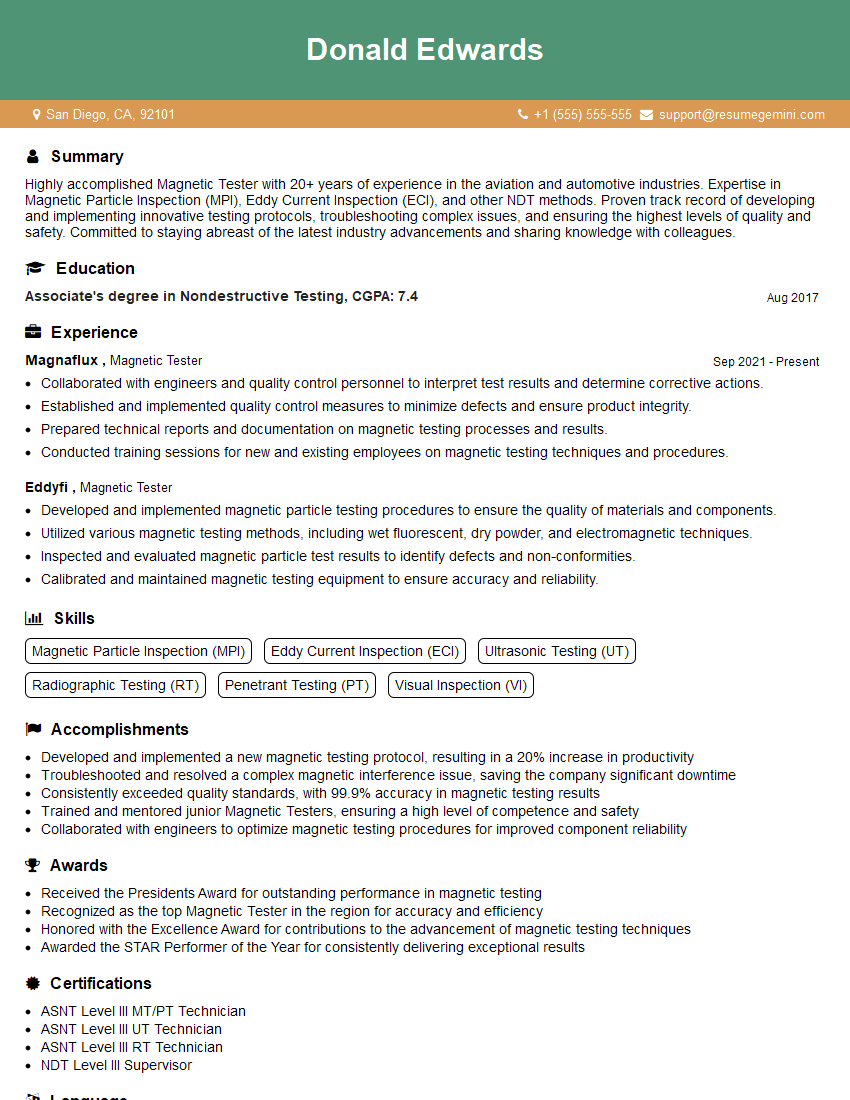

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Magnetic Tester

1. What is the principle behind magnetic particle inspection (MPI)?

MPI is a non-destructive testing (NDT) method that uses magnetic particles to detect surface and near-surface discontinuities in ferromagnetic materials.

- A strong magnetic field is applied to the material, which magnetizes it.

- Magnetic particles are then applied to the surface, which are attracted to areas where the magnetic field is distorted by discontinuities.

- The accumulation of magnetic particles at these locations indicates the presence of discontinuities.

2. Describe the different types of magnetic particle inspection techniques.

Continuous magnetization

- A continuous magnetic field is applied to the material during inspection.

- Suitable for detecting surface discontinuities.

Residual magnetization

- The material is magnetized before inspection, and the residual magnetic field is used to detect discontinuities.

- Suitable for detecting both surface and near-surface discontinuities.

Alternating current (AC) field magnetization

- An alternating current is applied to the material, creating a constantly changing magnetic field.

- Suitable for detecting surface and near-surface discontinuities in complex-shaped materials.

3. What are the advantages and disadvantages of MPI?

Advantages

- High sensitivity to surface and near-surface discontinuities.

- Relatively inexpensive and easy to perform.

- Can be used on a variety of ferromagnetic materials.

Disadvantages

- Only detects discontinuities that are open to the surface.

- Can be affected by the presence of non-ferromagnetic materials.

- Requires access to both sides of the material for continuous magnetization.

4. What are the factors that affect the accuracy and reliability of MPI results?

- Magnetic field strength

- Particle size and type

- Surface preparation

- Inspection time

- Operator experience

5. Describe the procedure for performing a magnetic particle inspection.

- Prepare the surface of the material to be inspected.

- Apply a magnetic field to the material.

- Apply magnetic particles to the surface.

- Inspect the surface for the accumulation of magnetic particles.

- Interpret the results and determine the presence and location of discontinuities.

6. What are the safety precautions that must be taken when performing MPI?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Ensure that the magnetic equipment is properly grounded.

- Do not operate magnetic equipment near flammable materials or in hazardous environments.

- Be aware of the potential for electrical hazards when working with magnetic equipment.

7. How do you interpret the results of a magnetic particle inspection?

- The size, shape, and distribution of the magnetic particle indications can provide information about the type and severity of the discontinuity.

- Reference standards can be used to compare the indications to known defects.

- The inspector’s experience and knowledge are also important factors in interpreting the results.

8. What are the applications of magnetic particle inspection?

- Automotive industry

- Aerospace industry

- Manufacturing industry

- Oil and gas industry

- Construction industry

9. What are the recent advancements in magnetic particle inspection?

- Automated MPI systems

- Remote MPI systems

- Advanced magnetic particle materials

- Image processing techniques

- Artificial intelligence (AI) in MPI

10. What are the current industry standards and codes for magnetic particle inspection?

- ASTM E1444 – Standard Practice for Magnetic Particle Examination

- ISO 9934 – Magnetic particle testing of ferromagnetic materials

- SNT-TC-1A – Recommended Practice for Personnel Qualification and Certification in Nondestructive Testing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Magnetic Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Magnetic Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Magnetic Testers play a crucial role in ensuring the quality and safety of products. Their primary responsibilities encompass:

1. Magnetic Particle Inspection (MPI)

Conduct MPI examinations on various materials and components to detect subsurface flaws, cracks, and other defects.

- Prepare test specimens by cleaning and magnetizing them.

- Apply magnetic particles to the surface and inspect for any irregularities or indications of defects.

2. Interpretation of Results

Interpret MPI results accurately, identify the nature and severity of defects, and generate detailed test reports.

- Classify defects based on size, shape, location, and orientation.

- Recommend appropriate corrective actions or further investigations if defects are found.

3. Equipment Maintenance and Calibration

Maintain and calibrate magnetic testing equipment, including MPI machines, power sources, and inspection tools.

- Perform regular equipment inspections and repairs to ensure optimal performance.

- Ensure compliance with industry standards and safety regulations.

4. Quality Control and Assurance

Adhere to established quality control procedures, document all test results, and maintain records for future reference.

- Follow established protocols to ensure the accuracy and reliability of tests.

- Participate in quality improvement initiatives and training programs.

Interview Tips

Preparing thoroughly for your Magnetic Tester interview is essential to make a strong impression. Here are some valuable tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and culture. Learn about the specific job requirements and responsibilities.

- Visit the company website and review any relevant materials.

- Connect with current or former employees on LinkedIn for insights into the workplace.

2. Highlight Relevant Experience and Skills

Emphasize your experience in MPI, interpretation of test results, and equipment maintenance. Showcase your technical abilities and understanding of industry standards.

- Quantify your accomplishments using specific numbers and metrics whenever possible.

- Provide examples of complex projects or problem-solving situations you have handled successfully.

3. Practice Common Interview Questions

Anticipate and prepare for common interview questions related to your technical abilities, experience, and work ethic.

- Prepare concise and well-rehearsed answers that demonstrate your knowledge and enthusiasm.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

4. Prepare Technical Questions

Demonstrate your interest and knowledge by asking thoughtful technical questions about the company’s testing procedures, equipment, or industry trends.

- Ask questions that show you are engaged and eager to learn more.

- Be respectful of the interviewer’s time and avoid asking overly technical or irrelevant questions.

5. Be Enthusiastic and Professional

Convey your passion for magnetic testing and your commitment to delivering high-quality results. Maintain a positive attitude and show enthusiasm for the role.

- Dress professionally and arrive on time for the interview.

- Be polite and respectful to everyone you encounter during the interview process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Magnetic Tester interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.