Are you gearing up for a career in Maintenance Equipment Operator (MEO)? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Maintenance Equipment Operator (MEO) and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

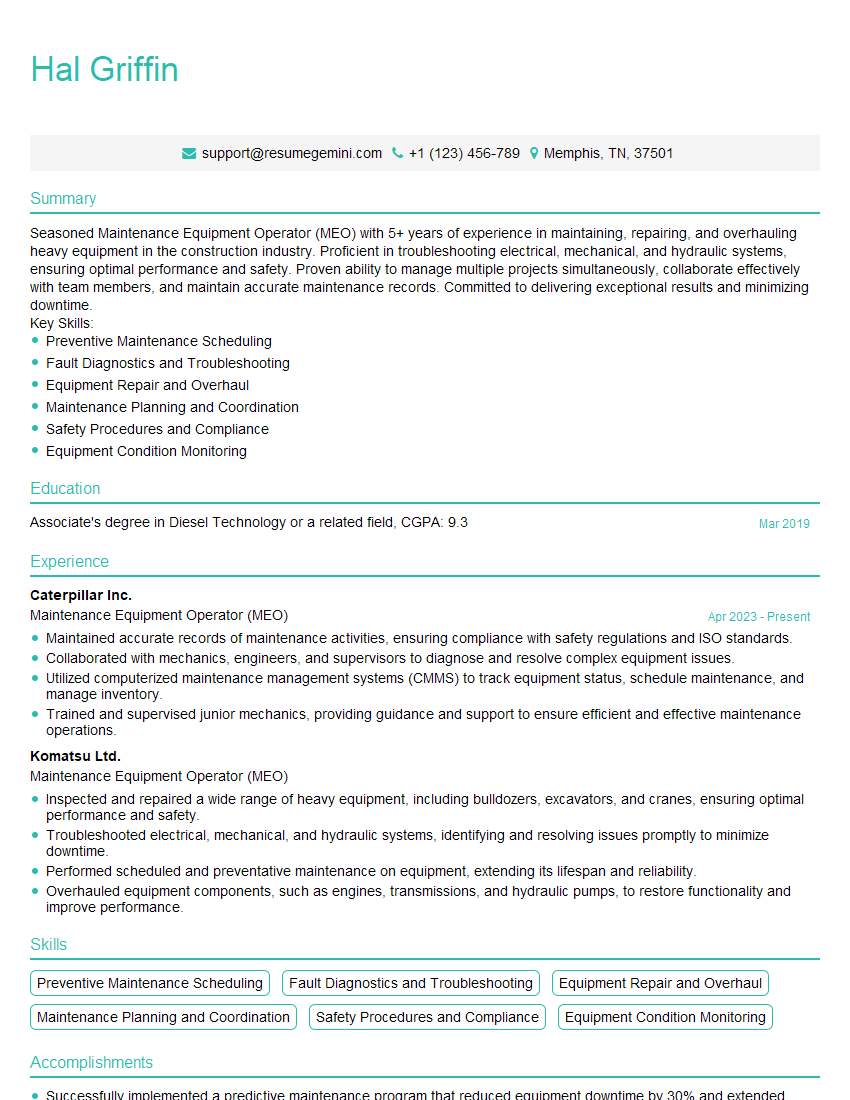

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Maintenance Equipment Operator (MEO)

1. What are the key responsibilities of a Maintenance Equipment Operator (MEO)?

As a Maintenance Equipment Operator, I would be responsible for:

- Performing preventive and corrective maintenance on a variety of equipment, including vehicles, machinery, and tools.

- Inspecting equipment to identify potential problems and making necessary repairs.

- Troubleshooting and diagnosing equipment malfunctions.

- Replacing worn or damaged parts.

- Maintaining a clean and organized work area.

- Following safety procedures and using proper tools and equipment.

- Working independently and as part of a team.

2. How do you prioritize your workload and manage multiple tasks?

Managing Workload

- I prioritize my workload based on the urgency and importance of each task.

- I use a to-do list or project management tool to keep track of my tasks.

- I break down large tasks into smaller, more manageable steps.

Managing Multiple Tasks

- I work on multiple tasks simultaneously when possible.

- I use time management techniques, such as the Pomodoro Technique, to stay focused and avoid burnout.

- I delegate tasks to others when necessary.

3. What are some of the challenges you have faced as a Maintenance Equipment Operator?

Some of the challenges I have faced as a Maintenance Equipment Operator include:

- Working in a fast-paced environment with tight deadlines.

- Diagnosing and repairing complex equipment malfunctions.

- Working with limited resources or tools.

- Dealing with unexpected equipment breakdowns.

- Maintaining a positive attitude and staying motivated in challenging situations.

4. What are some of the safety procedures that you follow as a Maintenance Equipment Operator?

As a Maintenance Equipment Operator, I follow several safety procedures to ensure the safety of myself and others, including:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hard hat.

- Following lockout/tagout procedures when working on equipment.

- Using proper tools and equipment for the job.

- Being aware of my surroundings and potential hazards.

- Reporting any unsafe conditions or equipment malfunctions to my supervisor.

5. What are some of the tools and equipment that you are familiar with using?

I am familiar with using a variety of tools and equipment, including:

- Hand tools, such as wrenches, screwdrivers, and pliers.

- Power tools, such as drills, saws, and grinders.

- Diagnostic equipment, such as multimeters and oscilloscopes.

- Welding and fabrication equipment.

- Computer-aided design (CAD) software.

6. What are some of the maintenance tasks that you have performed in the past?

Some of the maintenance tasks that I have performed in the past include:

- Replacing worn or damaged parts.

- Adjusting and calibrating equipment.

- Troubleshooting and repairing electrical and mechanical systems.

- Performing preventive maintenance, such as lubrication and cleaning.

- Inspecting equipment to identify potential problems.

7. What are some of the quality control procedures that you follow when performing maintenance tasks?

To ensure the quality of my work, I follow several quality control procedures, including:

- Following established maintenance procedures and specifications.

- Inspecting my work before and after completing a task.

- Testing equipment to ensure that it is functioning properly.

- Documenting all maintenance activities.

- Seeking feedback from my supervisor and colleagues.

8. What are some of the ways that you stay up-to-date on the latest maintenance technologies and best practices?

To stay up-to-date on the latest maintenance technologies and best practices, I:

- Attend industry conferences and workshops.

- Read industry publications and online resources.

- Network with other maintenance professionals.

- Participate in continuing education programs.

- Seek out opportunities to learn about new technologies and techniques.

9. What are some of the personal qualities that you believe are important for a successful Maintenance Equipment Operator?

I believe that the following personal qualities are important for a successful Maintenance Equipment Operator:

- Strong attention to detail.

- Ability to work independently and as part of a team.

- Excellent problem-solving skills.

- Good communication and interpersonal skills.

- Commitment to safety.

- Willingness to learn and grow.

- Positive attitude and strong work ethic.

10. What are your salary expectations for this role?

My salary expectations for this role are in line with the industry average for Maintenance Equipment Operators with my experience and qualifications. I am open to discussing my salary expectations further during the negotiation process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Maintenance Equipment Operator (MEO).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Maintenance Equipment Operator (MEO)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Maintenance Equipment Operators (MEOs) are technicians who keep machinery, equipment, and systems running smoothly in various industrial and commercial settings. Their responsibilities encompass a wide range of duties, ensuring the efficient and reliable operation of facilities and processes.

1. Maintenance Planning and Execution

- Conduct regular inspections and predictive maintenance to identify potential issues early on.

- Develop and execute preventative maintenance plans to minimize breakdowns and optimize equipment performance.

- Troubleshoot and repair mechanical, electrical, and hydraulic systems.

- Overhaul and rebuild equipment to extend its lifespan and reliability.

2. Equipment Monitoring and Control

- Monitor equipment performance and operating conditions using sensors and instrumentation.

- Maintain and calibrate control systems to ensure optimal functionality.

- Identify and correct deviations from normal operating parameters.

- Use diagnostic tools and techniques to detect and address equipment malfunctions.

3. Safety and Compliance

- Adhere to all safety regulations and procedures.

- Wear appropriate personal protective equipment (PPE) during maintenance operations.

- Conduct safety inspections and ensure compliance with industry standards.

- Train operators on safe equipment handling and maintenance practices.

4. Communication and Teamwork

- Communicate effectively with other technicians, engineers, and management.

- Provide clear and concise instructions and reports on maintenance activities.

- Collaborate with colleagues to resolve complex issues and improve maintenance outcomes.

- Participate in continuous improvement initiatives to enhance maintenance processes.

Interview Tips

Preparing for a MEO interview requires both technical knowledge and an understanding of industry best practices. Here are some valuable tips to help candidates ace their interview:

1. Highlight Technical Expertise

- Emphasize your proficiency in maintaining and repairing mechanical, electrical, and hydraulic systems.

- Showcase your knowledge of preventative maintenance strategies and diagnostic techniques.

- Provide examples of successful equipment overhauls and troubleshooting experiences.

2. Demonstrate Safety Awareness

- Articulate your commitment to safety and compliance in the workplace.

- Explain your experience in conducting safety inspections and training operators on safe practices.

- Stress the importance of wearing PPE and adhering to safety regulations.

3. Emphasize Communication Skills

- Highlight your ability to communicate effectively with both technical and non-technical audiences.

- Provide examples of how you effectively conveyed maintenance issues and recommendations.

- Show your willingness to collaborate with others and contribute to team-based problem-solving.

4. Prepare for Common Interview Questions

- Describe your experience in maintaining and repairing specific types of equipment.

- How do you prioritize maintenance tasks to ensure efficient operations?

- What are the most common equipment failures you have encountered and how did you resolve them?

- How do you ensure compliance with safety regulations while performing maintenance operations?

5. Ask Insightful Questions

- Ask about the company’s maintenance philosophy and best practices.

- Inquire about opportunities for professional development and career growth.

- Show interest in the company’s commitment to safety and sustainability.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Maintenance Equipment Operator (MEO) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!