Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Maintenance Journeyman position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

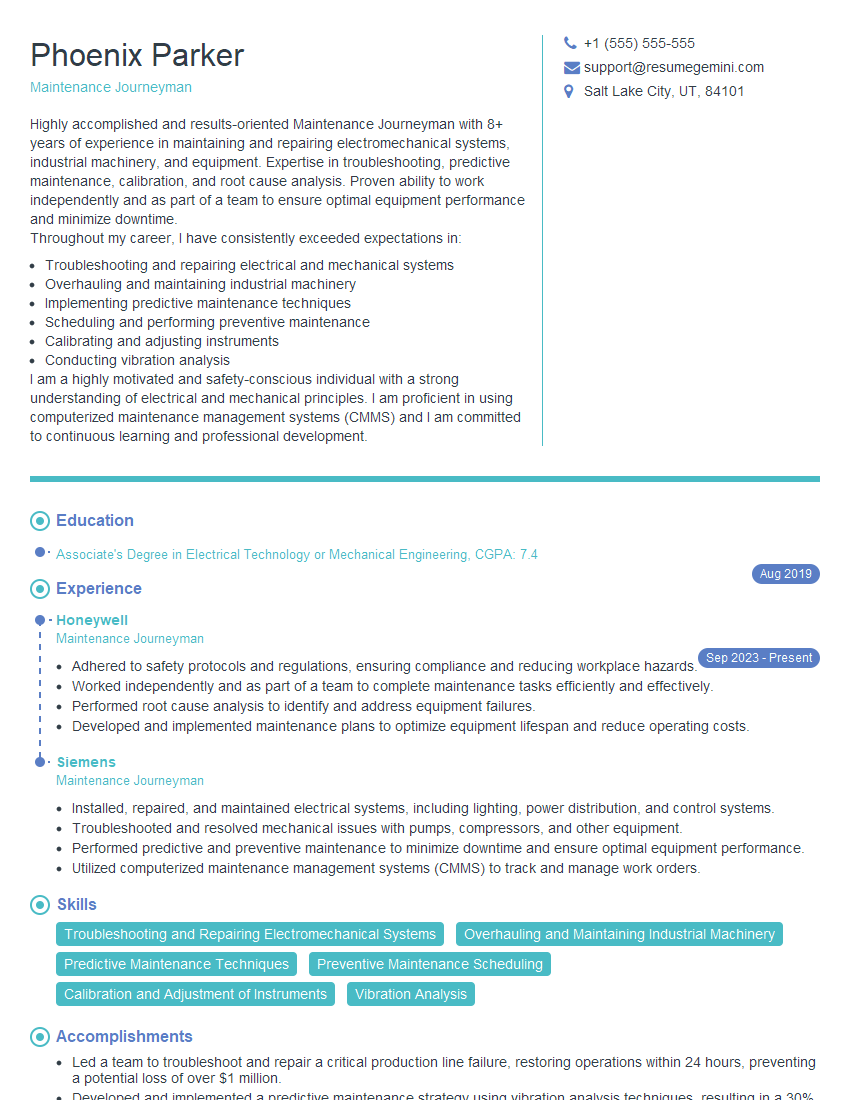

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Maintenance Journeyman

1. Explain how you approach troubleshooting a complex piece of machinery?

When troubleshooting a complex piece of machinery, I follow a systematic approach to identify and resolve the issue efficiently.

- Gather information: Collect data on the equipment’s operation, maintenance history, and any recent changes made.

- Visual inspection: Conduct a thorough visual inspection to identify any visible signs of damage, leaks, or misalignment.

- Test and diagnose: Use diagnostic tools and procedures to test the equipment’s functionality, identify potential faults, and determine the root cause.

- Repair and calibrate: Once the cause is identified, perform necessary repairs, adjust settings, and calibrate the equipment to restore its proper operation.

- Monitor and evaluate: Monitor the equipment’s performance after repairs to ensure the issue has been resolved and the system is operating as expected.

2. Describe your experience with predictive maintenance and condition monitoring techniques.

Preventive Maintenance

- Conduct regular inspections and maintenance tasks based on manufacturer guidelines and industry best practices.

- Monitor equipment using sensors and data analytics to identify potential issues early on.

- Use predictive maintenance software to analyze data and predict equipment failures before they occur.

Condition Monitoring Techniques

- Vibration analysis: Utilize vibration sensors to detect imbalances, bearing defects, and other mechanical issues.

- Thermography: Use thermal imaging cameras to identify hot spots, overheating components, and insulation failures.

- Ultrasonic testing: Employ ultrasonic equipment to detect leaks, cracks, and other defects in pipes, tanks, and vessels.

3. How do you ensure the safety of yourself and others while performing maintenance tasks?

To ensure safety, I adhere to established safety protocols and follow these key practices:

- Lockout/Tagout (LOTO): Implement LOTO procedures to isolate energy sources before working on equipment.

- Personal Protective Equipment (PPE): Wear appropriate PPE such as goggles, gloves, safety shoes, and respirators as required.

- Proper tools and equipment: Use the right tools and equipment for the job, ensuring they are properly maintained and calibrated.

- Risk assessment: Conduct thorough risk assessments prior to performing tasks, identifying potential hazards and implementing safety measures.

- Continuous training: Stay updated on safety regulations, industry best practices, and emergency response procedures.

4. Describe your experience with electrical troubleshooting and repair.

I have extensive experience in electrical troubleshooting and repair, which involves:

- Identifying electrical faults using multimeters, oscilloscopes, and other diagnostic tools.

- Testing electrical components such as transformers, motors, switches, and circuit breakers.

- Tracing wires and cables to locate open circuits, short circuits, and ground faults.

- Repairing electrical systems by replacing damaged components, soldering connections, and ensuring proper insulation.

- Ensuring electrical safety by verifying proper grounding, bonding, and circuit protection.

5. How do you stay up-to-date on industry trends and best practices in maintenance?

To stay current with industry trends and best practices, I engage in the following activities:

- Attend industry conferences, workshops, and webinars.

- Read technical journals, industry publications, and online forums.

- Network with other maintenance professionals, exchanging knowledge and experiences.

- Complete manufacturer training programs and certifications for specific equipment or systems.

- Participate in continuing education courses and workshops to enhance my skills and knowledge.

6. Explain how you prioritize maintenance tasks and allocate resources effectively.

I prioritize maintenance tasks based on the following criteria:

- Safety: Tasks that pose immediate safety hazards or risks are given top priority.

- Criticality: Tasks related to essential equipment or processes that impact production are prioritized.

- Urgency: Tasks that require immediate attention to prevent equipment failure or production downtime.

- Cost: Tasks that involve significant expenses or downtime are carefully considered.

- Predictive maintenance: Tasks identified through predictive maintenance techniques are scheduled to prevent potential failures.

I allocate resources effectively by:

- Assessing the availability of resources, including manpower, tools, and materials.

- Coordinating with other departments to ensure resource availability and minimize disruptions.

- Optimizing maintenance schedules to maximize resource utilization and minimize downtime.

7. Describe your approach to managing a team of maintenance technicians.

I believe in a collaborative and empowering leadership style when managing a team of maintenance technicians. My approach includes:

- Setting clear goals and expectations, ensuring the team understands their responsibilities.

- Providing training and development opportunities to enhance their skills and knowledge.

- Empowering technicians to take ownership of their work and make decisions within their scope of authority.

- Fostering a positive and supportive work environment where open communication is encouraged.

- Recognizing and rewarding team achievements and individual contributions.

8. How do you ensure that maintenance records are accurate, complete, and up-to-date?

Maintaining accurate, complete, and up-to-date maintenance records is crucial to ensure equipment reliability and regulatory compliance. I achieve this by:

- Establishing a clear record-keeping system and ensuring technicians follow it consistently.

- Using a computerized maintenance management system (CMMS) or other digital tools to capture and store data.

- Regularly reviewing and updating maintenance records to reflect completed tasks, repairs, and inspections.

- Implementing procedures for document control to ensure changes to records are properly approved and documented.

- Training technicians on the importance of accurate record-keeping and its impact on equipment reliability and safety.

9. How do you handle situations where you encounter equipment or issues that are beyond your expertise?

When encountering equipment or issues beyond my expertise, I take the following steps:

- Acknowledge my limitations and seek assistance from more experienced colleagues or external experts.

- Consult technical manuals, industry resources, and other sources to gather information and understand the issue.

- Collaborate with other departments, such as engineering or operations, to gain insights and perspectives.

- Attend training or workshops to enhance my knowledge and skills in specific areas.

- Prioritize safety and prevent further damage by isolating the equipment or taking appropriate measures.

10. How do you measure and evaluate the effectiveness of maintenance programs?

To measure and evaluate the effectiveness of maintenance programs, I use the following metrics:

- Equipment reliability: Tracking key performance indicators such as mean time between failures (MTBF) and mean time to repair (MTTR).

- Maintenance costs: Monitoring maintenance expenses, including labor, materials, and equipment.

- Production uptime: Assessing the percentage of time that equipment is operational and producing output.

- Customer satisfaction: Surveying customers or stakeholders to gauge their satisfaction with maintenance services.

- Compliance with regulations: Ensuring adherence to industry standards, safety protocols, and environmental regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Maintenance Journeyman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Maintenance Journeyman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Maintenance Journeymen are responsible for a wide range of tasks related to the upkeep and repair of machinery, equipment, and facilities. Their primary objective is to ensure that all equipment is operating efficiently and in a safe manner.

1. Equipment Maintenance

Journeymen are responsible for the preventive maintenance and repair of a variety of equipment and machinery, including electrical, mechanical, and plumbing systems.

- Conduct regular inspections to identify potential problems.

- Perform repairs and replacements to maintain equipment functionality.

2. Troubleshooting and Diagnostics

When equipment malfunctions, Journeymen are responsible for troubleshooting and diagnosing the problem, often using specialized tools and diagnostic equipment.

- Identify and resolve electrical, mechanical, and plumbing issues.

- Use diagnostic tools to pinpoint the source of the problem.

3. Safety Compliance

Journeymen must adhere to all safety regulations and protocols to ensure the safety of themselves, their colleagues, and the facility.

- Follow all safety protocols and procedures.

- Wear appropriate personal protective equipment (PPE).

4. Documentation

Journeymen are responsible for maintaining detailed records of all maintenance and repairs performed, including any parts used and time spent.

- Document all repairs and maintenance activities.

- Maintain accurate and up-to-date maintenance records.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Maintenance Journeyman position.

1. Research the Company

Before the interview, take the time to research the company, its industry, and its values. This will help you understand the company’s needs and demonstrate your interest in the position.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about the company’s sector.

2. Practice Your Answers

Prepare thoughtful responses to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”. Practice delivering your answers clearly and concisely.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on highlighting your skills and experiences that are relevant to the job.

3. Be Prepared with Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions about the company, the role, or the industry.

- Ask about the company’s plans for growth and expansion.

- Inquire about the specific responsibilities and challenges of the role.

4. Dress Professionally

First impressions matter, so dress appropriately for the interview. A clean, pressed suit or business casual attire is generally a safe choice.

- Choose clothes that fit well and are comfortable.

- Avoid wearing strong scents or excessive jewelry.

5. Be Punctual

Punctuality demonstrates respect for the interviewer’s time. Arrive at the interview location on time, or even a few minutes early.

- Plan your travel route in advance to avoid delays.

- If you encounter any unexpected circumstances, call or email the interviewer immediately.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Maintenance Journeyman interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!