Feeling lost in a sea of interview questions? Landed that dream interview for Maintenance Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Maintenance Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

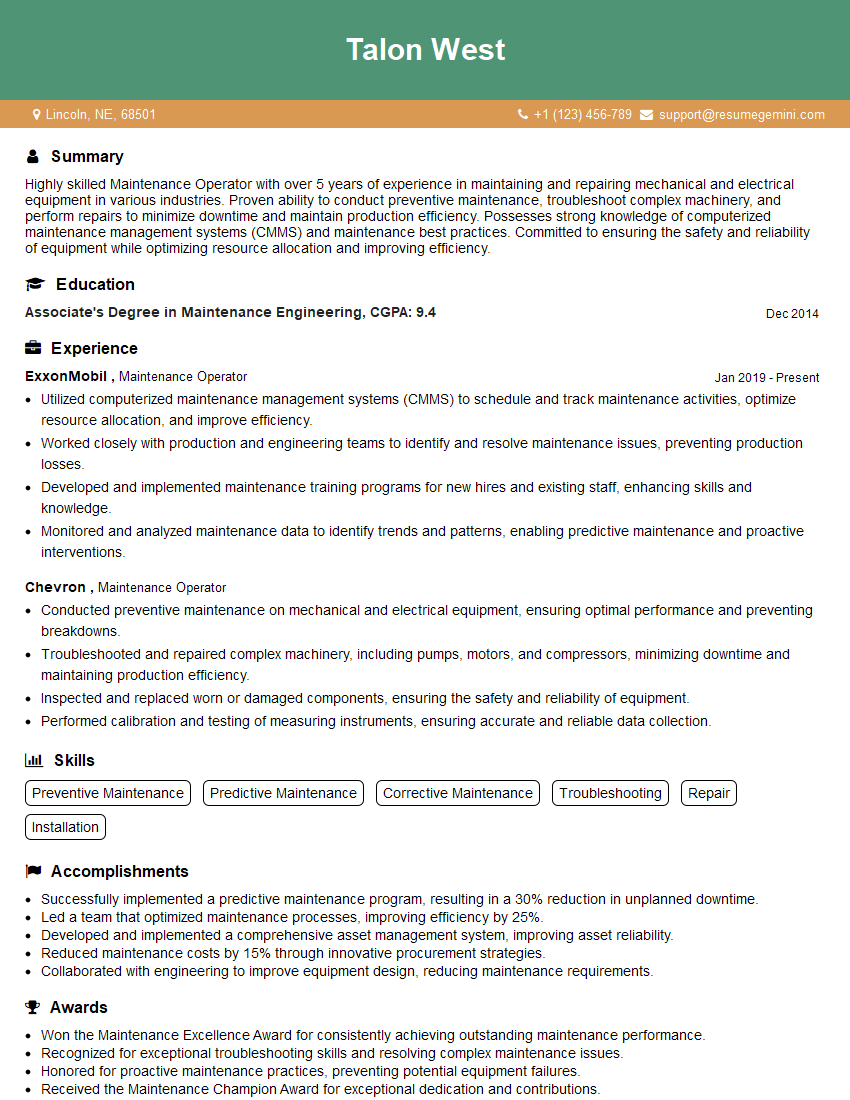

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Maintenance Operator

1. Describe the steps involved in troubleshooting a malfunctioning industrial machine?

The steps involved in troubleshooting a malfunctioning industrial machine typically include:

- Identify the problem

- Gather information

- Generate possible solutions

- Test the solutions

- Verify the results

2. How do you prioritize maintenance tasks based on urgency and importance?

Evaluating Urgency

- Assess the immediate impact of the task on production

- Consider the potential safety risks involved

Evaluating Importance

- Determine the long-term consequences of delaying the task

- Consider the impact on overall equipment reliability

3. Explain the importance of preventative maintenance and how you implement it in your work?

Preventative maintenance is crucial for maximizing equipment uptime, reducing unplanned downtime, and extending the lifespan of assets. I implement it by:

- Following manufacturer’s recommended maintenance schedules

- Performing regular inspections and condition monitoring

- Replacing components before they fail

- Keeping detailed maintenance records

4. How do you stay updated with the latest maintenance technologies and best practices?

I stay updated with the latest maintenance technologies and best practices through:

- Attending industry conferences and training sessions

- Reading technical publications and online resources

- Networking with other maintenance professionals

- Seeking opportunities for professional development

5. Describe your experience in managing a team of maintenance technicians?

As a Maintenance Manager, I was responsible for leading a team of maintenance technicians. My responsibilities included:

- Setting performance goals and providing guidance

- Assigning work and ensuring timely completion

- Training and mentoring technicians

- Monitoring team performance and providing feedback

6. How do you handle situations where multiple maintenance tasks need to be completed simultaneously?

When multiple maintenance tasks need to be completed simultaneously, I prioritize them based on urgency and importance, and then:

- Delegate tasks to qualified technicians

- Coordinate and oversee the execution of tasks

- Monitor progress and make necessary adjustments

- Communicate with stakeholders to keep them informed

7. How do you ensure that maintenance work is completed safely and efficiently?

To ensure that maintenance work is completed safely and efficiently, I:

- Follow established safety protocols

- Identify and assess potential hazards

- Use appropriate tools and equipment

- Plan and prepare work areas

- Monitor progress and make adjustments as needed

8. How do you manage spare parts inventory and ensure that critical parts are available when needed?

I manage spare parts inventory by:

- Maintaining an up-to-date inventory list

- Monitoring stock levels and reordering as needed

- Storing parts in a secure and organized manner

- Working with suppliers to ensure timely delivery of critical parts

9. Describe your experience in using computerized maintenance management systems (CMMS)?

I have extensive experience in using computerized maintenance management systems (CMMS), including Maximo and SAP PM. I use these systems to:

- Manage work orders

- Track maintenance history

- Monitor equipment performance

- Generate reports and analytics

10. How do you stay motivated and engaged in your work as a Maintenance Operator?

I stay motivated and engaged in my work as a Maintenance Operator by:

- Taking pride in my work and seeing the positive impact it has

- Continuously learning and developing my skills

- Working with a supportive team

- Seeing the results of my efforts in maintaining and improving the equipment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Maintenance Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Maintenance Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Maintenance Operators are responsible for the upkeep and maintenance of machines, equipment, and facilities. They ensure that everything is running smoothly and efficiently, and they take care of any repairs or troubleshooting that may arise.

1. Equipment Maintenance and Repair

Maintenance Operators perform regular maintenance on equipment to prevent breakdowns and ensure optimal performance. They also troubleshoot and repair equipment when problems occur, using their knowledge of mechanics, electricity, and other relevant areas.

- Inspect and maintain equipment according to established schedules.

- Repair and replace faulty components, such as motors, bearings, and gears.

2. Troubleshooting and Problem Solving

Maintenance Operators identify and resolve problems with equipment and facilities. They analyze symptoms, diagnose the root cause of the issue, and implement appropriate solutions.

- Troubleshoot equipment problems using diagnostic tools and techniques.

- Identify and repair electrical, mechanical, and hydraulic issues.

3. Calibration and Adjustment

Maintenance Operators calibrate and adjust equipment to ensure accuracy and precision. They use specialized tools and techniques to ensure that equipment meets required specifications.

- Calibrate measuring instruments and equipment using standard references.

- Adjust equipment settings to optimize performance and efficiency.

4. Preventive Maintenance

Maintenance Operators implement preventive maintenance programs to minimize equipment downtime and extend the lifespan of assets. They perform regular inspections, cleanings, and lubrication to prevent problems before they occur.

- Develop and implement preventive maintenance plans and schedules.

- Conduct routine inspections and identify potential problems.

Interview Tips

To ace a Maintenance Operator interview, candidates should be prepared to discuss their technical skills, problem-solving abilities, and commitment to safety. Here are some tips to help you prepare:

1. Research the Company and Role

Before the interview, take the time to research the company and the specific Maintenance Operator role you’re applying for. This will help you understand the company’s culture, values, and the specific responsibilities of the position.

- Visit the company’s website to learn about their mission, products/services, and recent news.

- Review the job description carefully to identify the key requirements and responsibilities.

2. Highlight Your Technical Skills

Maintenance Operators need to have a strong foundation in mechanical, electrical, and hydraulic systems. Be prepared to discuss your experience with repairing and maintaining equipment, as well as your knowledge of different types of tools and equipment.

- Provide specific examples of repairs you’ve made or troubleshooting you’ve done.

- Discuss your experience with different types of equipment, such as pumps, motors, and conveyors.

3. Emphasize Your Problem-Solving Abilities

Maintenance Operators often need to troubleshoot and resolve problems with equipment. Be prepared to discuss your problem-solving process and provide examples of how you’ve successfully resolved issues in the past.

- Describe a situation where you identified a problem, diagnosed the root cause, and implemented a solution.

- Explain how you approach troubleshooting and problem-solving, and the steps you take to ensure a successful outcome.

4. Demonstrate Your Commitment to Safety

Safety is paramount in a Maintenance Operator role. Be prepared to discuss your commitment to safety and the steps you take to ensure a safe work environment.

- Provide examples of how you’ve followed safety protocols and procedures.

- Explain how you stay up-to-date on safety regulations and industry best practices.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Maintenance Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Maintenance Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.