Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Major Assembly Lineman interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Major Assembly Lineman so you can tailor your answers to impress potential employers.

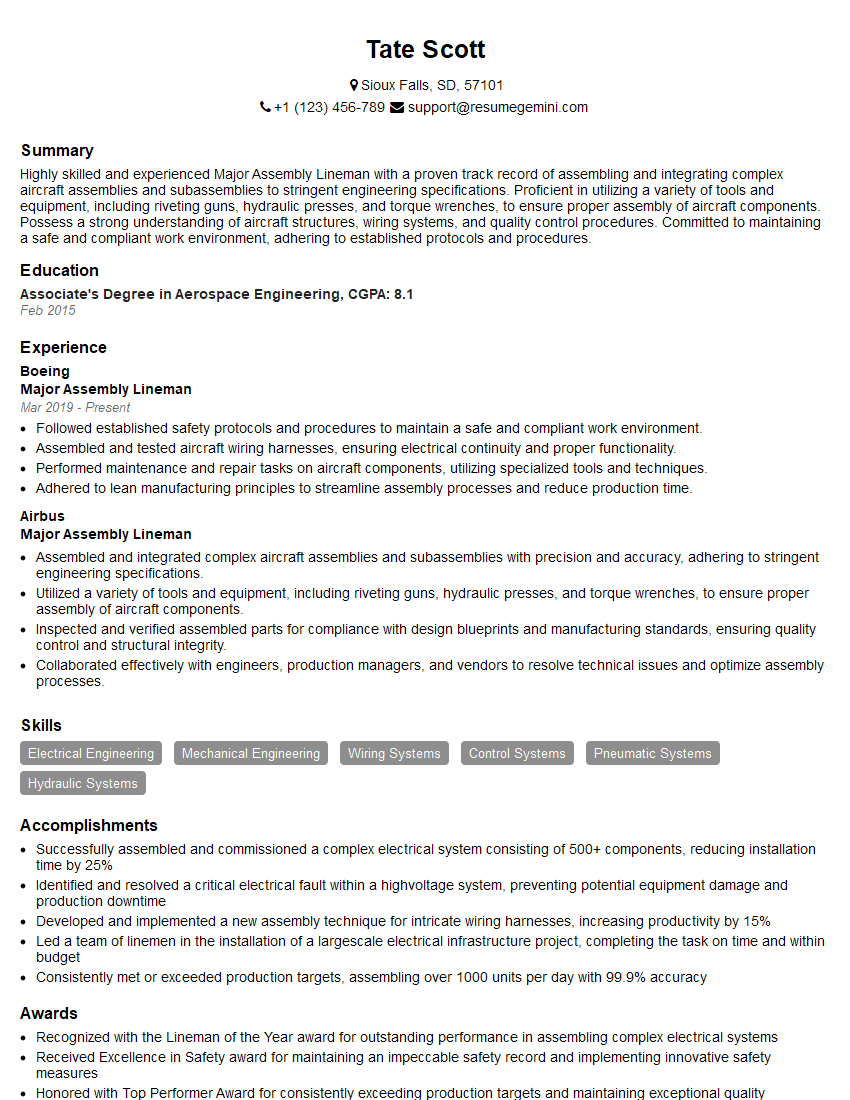

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Major Assembly Lineman

1. What are the key responsibilities of a Major Assembly Lineman?

As a Major Assembly Lineman, my primary responsibilities include:

- Assembling and installing major components of aircraft, such as wings, fuselage, and engines.

- Inspecting and testing assembled components to ensure they meet specifications.

- Working with engineers and other technicians to resolve assembly issues and improve processes.

2. Describe the process of assembling a major aircraft component, such as a wing.

Sub-assembly Preparation:

- Reviewing assembly drawings and specifications.

- Gathering necessary materials and tools.

- Preparing work area and establishing proper safety protocols.

Mating of Components:

- Fitting and aligning structural components, such as spars and ribs.

- Using specialized tools and techniques to secure components with fasteners and adhesives.

- Ensuring proper alignment and dimensional accuracy.

Installation of Systems:

- Integrating hydraulic, electrical, and control systems.

- Connecting and testing wiring harnesses, hoses, and other components.

- Verifying the functionality and performance of installed systems.

Final Assembly and Inspection:

- Joining completed sub-assemblies to form the final component.

- Conducting thorough inspections to ensure compliance with specifications.

- Documenting assembly procedures and any deviations or modifications.

3. What is the importance of following assembly instructions and specifications precisely?

Adhering to assembly instructions and specifications is crucial for several reasons:

- Safety: Ensuring proper assembly prevents structural failures, malfunctions, and potential hazards.

- Quality: Compliance with specifications guarantees the component meets performance standards and design requirements.

- Efficiency: Following instructions streamlines assembly processes, reducing errors and rework.

- Documentation: Accurate documentation supports traceability, maintenance, and regulatory compliance.

- Standardization: Uniform assembly practices ensure consistency and interchangeability of components.

4. How do you troubleshoot assembly issues?

In the event of assembly issues, I follow a systematic approach to troubleshooting:

- Identify the problem: Review symptoms, inspect affected components, and examine assembly instructions.

- Analyze the cause: Determine potential root causes, such as incorrect part orientation, loose fasteners, or faulty wiring.

- Develop a solution: Propose and implement modifications, repairs, or replacements to resolve the issue.

- Test and verify: Conduct appropriate tests to ensure the solution has addressed the problem effectively.

- Document and communicate: Record findings, corrective actions taken, and any lessons learned.

5. What are the safety precautions to consider when working on major aircraft components?

- Proper grounding and bonding to prevent electrical hazards.

- Use of personal protective equipment, such as gloves, safety glasses, and coveralls.

- Adherence to lockout/tagout procedures to prevent accidental activation of equipment.

- Awareness of overhead cranes and moving machinery to avoid collisions.

- Regular inspection of tools and equipment to ensure safe working conditions.

- Communication and coordination with colleagues to minimize risks.

6. How do you stay updated with the latest assembly techniques and industry standards?

To stay abreast of advancements in assembly techniques and industry standards, I engage in:

- Continuing education: Attending workshops, seminars, and industry events.

- Reading trade publications and technical journals: Staying informed about best practices and emerging technologies.

- Collaborating with colleagues and industry experts: Exchanging knowledge and seeking advice from peers.

- Participating in professional organizations: Accessing resources and networking with other professionals in the field.

- Online learning platforms: Utilizing online courses and certifications to enhance skills.

7. What is the importance of teamwork in aircraft assembly?

- Coordination and efficiency: Teamwork ensures smooth communication, task allocation, and timely completion of assembly processes.

- Problem-solving and innovation: Collaborative efforts allow for brainstorming, sharing of ideas, and finding innovative solutions to assembly challenges.

- Safety and quality: Teamwork promotes a culture of safety consciousness and peer review, leading to improved quality of work.

- Knowledge sharing: Working together enables the transfer of skills, knowledge, and best practices among team members.

- Motivation and morale: A collaborative work environment fosters motivation, a sense of accomplishment, and job satisfaction.

8. Describe your experience working with composite materials in aircraft assembly.

I have extensive experience working with composite materials, including:

- Layup and curing: Applying composite prepregs, fabrics, and resins, and utilizing vacuum bagging and autoclaves for curing.

- Structural analysis: Understanding the properties and performance of composite materials, and using engineering tools to analyze structural integrity.

- Quality control: Performing non-destructive testing (NDT) to inspect composite structures for defects and ensure compliance with specifications.

- Repair and maintenance: Conducting repairs on composite components using specialized techniques and materials.

- Adherence to safety protocols: Following strict safety guidelines when handling and working with composite materials.

9. What is your understanding of additive manufacturing in aircraft assembly?

Additive manufacturing, also known as 3D printing, has gained significant traction in aircraft assembly:

- Complex part production: Enables the fabrication of intricate and lightweight components with complex geometries.

- Rapid prototyping and testing: Allows for quick production of prototypes for testing and design validation.

- Customization and customization: Supports the creation of customized parts to meet specific requirements.

- Material optimization: Enables the use of lightweight and high-performance materials to enhance aircraft performance.

- Reduced lead times and costs: Streamlines production processes, potentially reducing lead times and manufacturing costs.

10. How do you stay motivated and engaged in a demanding role like Major Assembly Lineman?

Staying motivated and engaged in this demanding role requires a combination of:

- Passion for aviation: A deep interest and enthusiasm for the aerospace industry helps drive my motivation.

- Challenges and learning: Embracing new challenges and opportunities for growth keeps me engaged and eager to develop my skills.

- Teamwork and camaraderie: Working alongside a skilled and dedicated team provides support and motivation.

- Seeing the impact: Comprehending the significance of my work in contributing to the production of safe and reliable aircraft fosters a sense of purpose.

- Professional development: Pursuing ongoing education and certification enhances my skills and keeps me motivated.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Major Assembly Lineman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Major Assembly Lineman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Major Assembly Linemen are responsible for assembling, installing, and testing major components of products. These components can be large and complex, such as aircraft wings or turbines, and require a high level of precision and skill to assemble correctly.

1. Assembly of Major Components

Major Assembly Linemen are responsible for assembling major components of products, such as aircraft wings or turbines. This involves using a variety of tools and equipment to join, fit, and align components according to specifications.

- Assemble and join major components using precision tools and equipment

- Ensure correct alignment and fit of components using measuring and alignment tools

2. Installation of Components

Major Assembly Linemen also install components onto larger assemblies or structures. This may involve using cranes, hoists, or other equipment to lift and position components.

- Install components onto larger assemblies or structures using cranes, hoists, or other equipment

- Secure and fasten components using bolts, nuts, and other fasteners

3. Testing and Inspection

Major Assembly Linemen are responsible for testing and inspecting assembled components to ensure that they meet specifications and function properly.

- Conduct tests to verify the proper functioning of assembled components

- Inspect components for defects or damage using visual and non-destructive testing methods

4. Maintenance and Repair

Major Assembly Linemen may also be responsible for maintaining and repairing assembled components. This may involve troubleshooting problems, replacing parts, or performing other maintenance tasks.

- Perform maintenance tasks to ensure the proper functioning of assembled components

- Troubleshoot problems and replace defective parts or components

Interview Tips

Preparing for an interview for a Major Assembly Lineman position can be challenging, but with the right strategies, you can increase your chances of success. Here are some tips to help you prepare:

1. Research the Company and Position

Take time to learn about the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and what they’re looking for in a candidate.

- Visit the company’s website and social media pages

- Read articles and news stories about the company

2. Practice Your Answers to Common Interview Questions

There are certain questions that are commonly asked in interviews for Major Assembly Lineman positions. By practicing your answers to these questions, you can feel more confident and prepared during the interview.

- Tell me about your experience assembling major components

- Describe a time when you had to troubleshoot a problem with an assembled component

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- What are the company’s growth plans for the future?

- What are the biggest challenges facing the company right now?

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress professionally for your interview. Also, arrive on time to show that you’re respectful of the interviewer’s time.

- Wear a suit or business casual attire

- Be punctual for your interview

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Major Assembly Lineman role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.