Are you gearing up for an interview for a Malted Milk Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Malted Milk Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

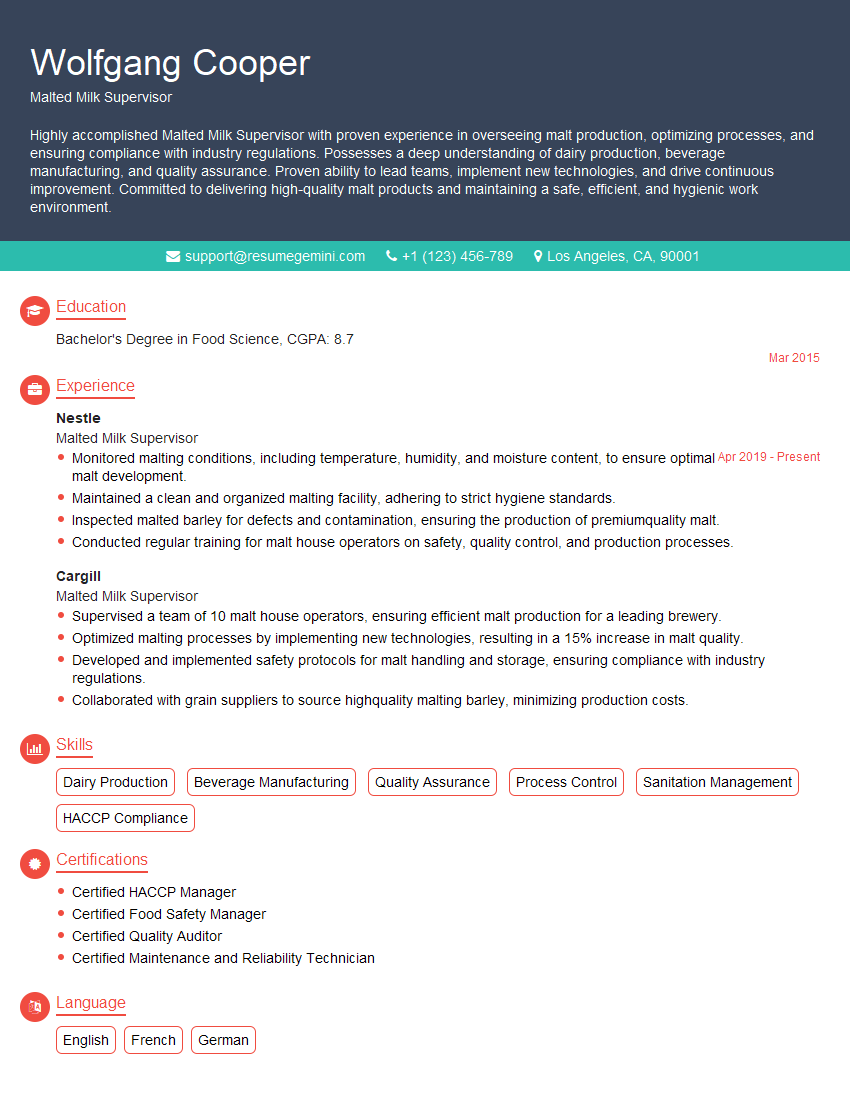

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Malted Milk Supervisor

1. What are the critical quality control points in the production of malted milk?

The critical quality control points in the production of malted milk are:

- Raw material inspection

- Milling

- Mashing

- Wort filtration

- Wort boiling

- Cooling

- Fermentation

- Maturation

- Packaging

2. What is the role of barley in the production of malted milk?

Barley is a cereal grain that is the primary ingredient in malted milk. It is a good source of carbohydrates, protein, and fiber. Barley is malted by soaking it in water and then allowing it to germinate. This process converts the starches in the barley into sugars, which are then used by the yeast to produce alcohol and carbon dioxide during fermentation.

Role of barley in malted milk production

- Provides carbohydrates for fermentation

- Provides protein for yeast growth

- Provides fiber for body

- Contributes to the flavor and aroma of malted milk

3. What are the different types of malted milk products?

There are two main types of malted milk products:

- Malted milk powder

- Malted milk beverages

Malted milk powder is a dry powder that is made from malted barley, wheat flour, and milk powder. It is used as a flavoring and nutritional supplement in a variety of food and beverage products, such as milkshakes, smoothies, and baked goods.

Malted milk beverages are made from malted milk powder, milk, and sugar. They are a popular breakfast drink and can also be used as a dessert or snack.

4. What are the key factors that affect the quality of malted milk?

The key factors that affect the quality of malted milk include:

- The quality of the raw materials

- The malting process

- The fermentation process

- The packaging process

5. What are the common defects that can occur in the production of malted milk?

The common defects that can occur in the production of malted milk include:

- Off-flavors

- Off-colors

- Sediment

- Contamination

6. What are the corrective actions that can be taken to address defects in the production of malted milk?

The corrective actions that can be taken to address defects in the production of malted milk include:

- Identifying the cause of the defect

- Implementing corrective actions to eliminate the cause of the defect

- Verifying that the corrective actions have been effective

7. What are the key performance indicators (KPIs) that are used to measure the effectiveness of a malted milk production process?

The key performance indicators (KPIs) that are used to measure the effectiveness of a malted milk production process include:

- Product quality

- Production yield

- Production efficiency

- Cost of production

8. What are the latest trends in the malted milk industry?

The latest trends in the malted milk industry include:

- The increasing demand for malted milk products in emerging markets

- The development of new malted milk products with innovative flavors and ingredients

- The increasing use of malted milk products in food and beverage applications

9. What are the challenges facing the malted milk industry?

The challenges facing the malted milk industry include:

- The rising cost of raw materials

- The increasing competition from other beverage products

- The changing consumer preferences

10. What are the opportunities for growth in the malted milk industry?

The opportunities for growth in the malted milk industry include:

- The increasing demand for malted milk products in emerging markets

- The development of new malted milk products with innovative flavors and ingredients

- The increasing use of malted milk products in food and beverage applications

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Malted Milk Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Malted Milk Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Malted Milk Supervisor is responsible for overseeing the production of malted milk, ensuring that it meets quality and safety standards. They work in a manufacturing environment and supervise a team of employees.

1. Production Management

The Malted Milk Supervisor is responsible for planning, organizing, and directing the production of malted milk. This includes scheduling production runs, allocating resources, and monitoring progress.

- Plan and schedule production runs

- Allocate resources, including equipment, materials, and personnel

- Monitor production progress and make adjustments as needed

2. Quality Control

The Malted Milk Supervisor is responsible for ensuring that the malted milk meets quality standards. This includes conducting inspections, testing samples, and taking corrective action when necessary.

- Conduct inspections of raw materials and finished products

- Test samples of malted milk to ensure that it meets specifications

- Take corrective action when quality problems are identified

3. Safety Management

The Malted Milk Supervisor is responsible for ensuring that the production environment is safe for employees. This includes conducting safety inspections, training employees on safety procedures, and enforcing safety regulations.

- Conduct safety inspections of the production area

- Train employees on safety procedures

- Enforce safety regulations

4. Employee Management

The Malted Milk Supervisor is responsible for supervising a team of employees. This includes hiring, training, and evaluating employees. The supervisor also provides feedback and guidance to employees.

- Hire, train, and evaluate employees

- Provide feedback and guidance to employees

- Resolve employee issues and conflicts

Interview Tips

Preparing for an interview for a Malted Milk Supervisor position can be daunting, but by following a few simple tips, you can increase your chances of success.

1. Research the Company and Position

Before the interview, take some time to research the company and the position. This will help you understand the company’s culture, values, and goals. It will also help you understand the specific requirements of the position and what the interviewer is looking for.

2. Practice Your Answers

Once you have a good understanding of the company and position, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing a suit or business casual attire.

4. Be on Time

Punctuality is important, so make sure you arrive for your interview on time. This shows the interviewer that you are respectful of their time and that you are serious about the position.

5. Be Enthusiastic and Positive

The interviewer wants to see that you are enthusiastic about the position and that you are a positive person. Be sure to smile and make eye contact with the interviewer.

6. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are eager to learn more.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Malted Milk Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.