Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Maltster interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Maltster so you can tailor your answers to impress potential employers.

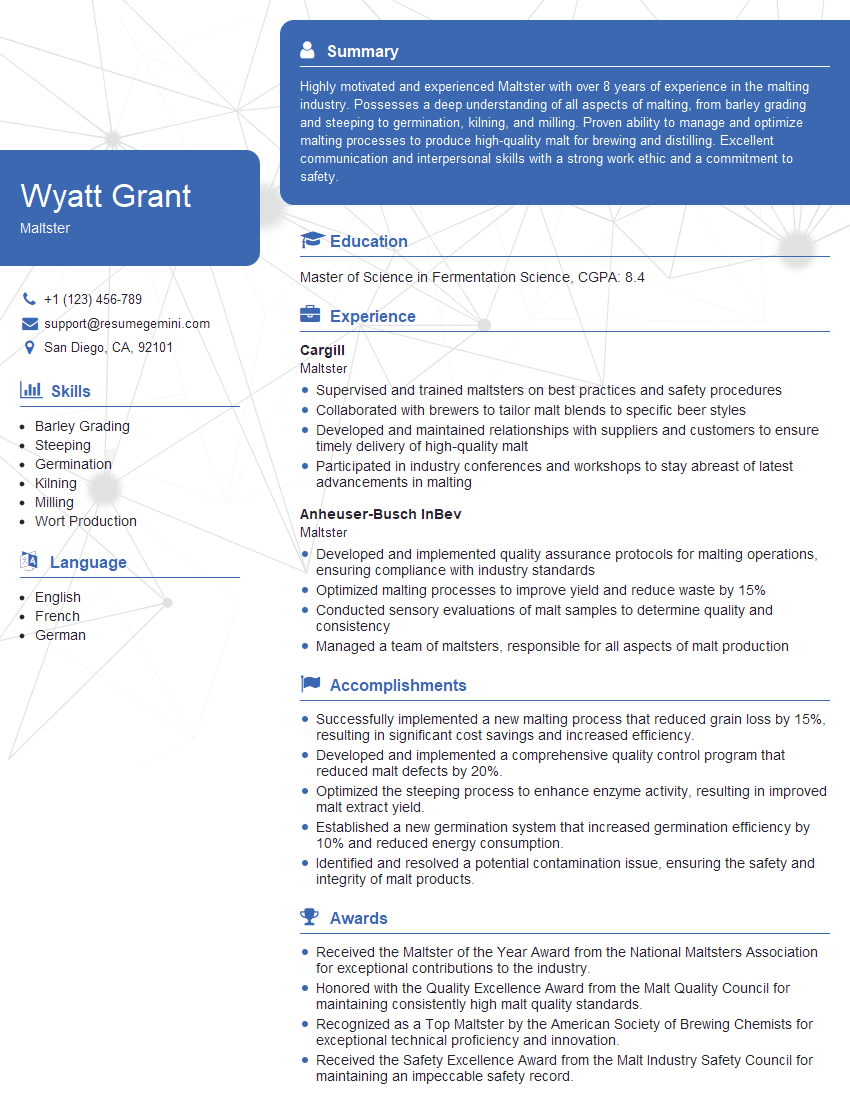

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Maltster

1. What are the key steps involved in the malting process?

- Steeping: Soaking barley in water to activate enzymes.

- Germination: Allowing barley to sprout, developing enzymes necessary for modification.

- Kilning: Drying the germinated barley to stop germination and develop flavor and color.

- Roasting: Optional step to enhance flavor and color.

2. Describe the role of enzymes in the modification of barley during malting.

Proteases

- Break down proteins into amino acids, providing nutrients for yeast.

- Improve wort clarity and reduce viscosity.

Amylases

- Convert starch into fermentable sugars, providing energy for yeast.

- Optimizing sugar content and fermentability.

Glucanases

- Break down beta-glucans, reducing wort viscosity and improving filtration.

3. How do you determine the optimal steeping time and temperature for barley?

- Steeping time: Balance between allowing sufficient enzyme activation and minimizing rootlet growth.

- Steeping temperature: Control enzyme activity and prevent microbiological contamination.

- Monitor moisture content and temperature: Ensure optimal hydration and enzyme activity.

4. What are the different types of barley used for malting and how do their characteristics affect the final malt?

- Two-row barley: High enzymatic activity, producing malts with good extract yield and fermentability.

- Six-row barley: Lower enzymatic activity, yielding malts with higher protein and lower extract.

- Spring barley: Harvested in summer, known for its high protein content and lower starch.

- Winter barley: Harvested in spring, with lower protein and higher starch, resulting in malts with good extract yield.

5. Explain the process of kilning and its impact on malt flavor and color.

- Low kilning temperatures: Produce pale malts with subtle flavors and light colors.

- Higher kilning temperatures: Develop darker malts with more pronounced flavors (e.g., chocolate, roasted).

- Maillard reaction: Occurs during kilning, contributing to color and flavor development.

6. How do you ensure the quality and consistency of malt produced?

- Raw material selection: Inspect barley for quality and consistency.

- Process control: Monitor steeping, germination, kilning parameters to maintain optimal conditions.

- Analytical testing: Conduct malt analyses (e.g., extract yield, moisture, protein) to verify quality.

- Sensory evaluation: Perform taste tests to evaluate flavor and color characteristics.

7. What are the common quality defects in malt and how can they be prevented?

- Over-malting: Excessive enzymatic modification, resulting in reduced extract yield and wort clarity.

- Under-malting: Insufficient enzymatic modification, leading to poor extract yield and reduced fermentability.

- Gibberellic acid (GA) levels: High levels can affect seed germination and malt quality. Monitoring barley sources and germination conditions helps prevent this.

8. How do you manage the storage and handling of malt to maintain its quality?

- Moisture control: Store malt at appropriate moisture levels to prevent spoilage and maintain enzymatic activity.

- Temperature control: Store malt in cool, dry environments to avoid deterioration.

- Pest and rodent control: Implement measures to prevent contamination and maintain sanitary conditions.

9. What are the emerging trends in malting technology and research?

- Precision malting: Using sensors and data analysis to optimize malting process for specific beer styles.

- Specialty malts: Developing malts with unique flavor profiles and functionalities for craft brewing.

- Sustainable malting practices: Reducing water consumption, energy usage, and environmental impact.

10. How would you approach the challenge of developing a new type of malt for a specific beer style?

- Research and market analysis: Understand the target beer style and its flavor profile.

- Laboratory trials: Experiment with different barley varieties, steeping time and temperatures, and kilning conditions.

- Pilot-scale production: Produce small batches of malt to evaluate performance in brewing trials.

- Sensory evaluation: Conduct taste tests to determine the optimal flavor and color characteristics.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Maltster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Maltster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Maltsters play a vital role in the brewing industry. They are responsible for the production of malt, the key ingredient in beer. The job responsibilities of a Maltster include:

1. Sourcing and selecting barley

Maltsters must have a deep understanding of barley varieties and their suitability for malting. They work closely with farmers to source and select the best quality barley for their needs.

- Inspecting barley for quality and cleanliness

- Determining the moisture content and protein levels of barley

2. Steeping the barley

The first step in the malting process is steeping the barley in water. This process helps to activate the enzymes in the barley, which will later convert the starches into sugars.

- Monitoring the temperature and pH of the steeping water

- Ensuring that the barley is evenly steeped

3. Germinating the barley

Once the barley has been steeped, it is transferred to a germination chamber. Here, the barley is spread out on a bed of barley straw and allowed to germinate. During germination, the enzymes in the barley convert the starches into sugars.

- Controlling the temperature and humidity of the germination chamber

- Monitoring the progress of germination

4. Kilning the barley

The final step in the malting process is kilning. During kilning, the germinated barley is dried in a kiln. This process stops the germination process and dries the barley to a moisture content of about 4-6%.

- Setting and maintaining the temperature of the kiln

- Monitoring the progress of the kilning process

Interview Tips

To ace an interview for a Maltster position, it is important to be prepared. Here are a few tips:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you to better understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website

- Read articles about the company and the industry

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions

- Be specific and provide examples

- Tailor your answers to the specific company and position

3. Be enthusiastic and passionate

Maltsters are passionate about their work. They are proud of the role they play in the brewing industry and they are always looking for ways to improve the quality of their malt. If you are enthusiastic and passionate about malting, this will come across in the interview.

- Show your interest in the brewing industry

- Talk about your experience with malting

- Explain why you are passionate about malting

4. Be prepared to ask questions

Asking questions at the end of the interview shows that you are interested in the position and that you are taking the interview seriously. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s culture and values

- Ask about the specific requirements of the job

- Ask about the company’s plans for the future

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Maltster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!