Feeling lost in a sea of interview questions? Landed that dream interview for Mandrel Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mandrel Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

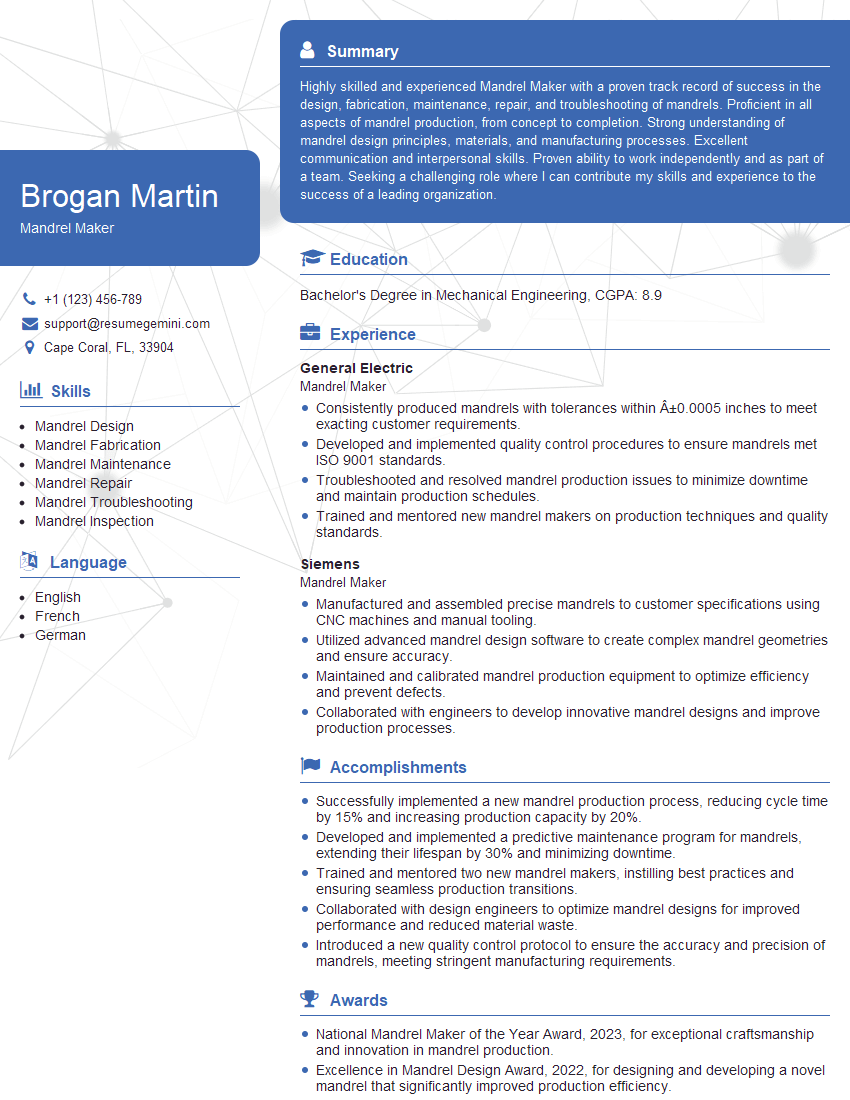

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mandrel Maker

1. What are the different types of mandrels used in the manufacturing industry?

There are various types of mandrels used in the manufacturing industry, including:

- Straight mandrels: Used for holding cylindrical workpieces.

- Tapered mandrels: Used for holding conical workpieces.

- Collet mandrels: Used for holding workpieces that require high accuracy and concentricity.

- Expanding mandrels: Used for holding workpieces with varying diameters.

- Dead center mandrels: Used to support the tailstock of a lathe.

2. Explain the process of mandrel making.

Material Selection

- Selecting the appropriate material, such as steel, aluminum, or composite, based on the mandrel’s intended use.

Machining

- Turning, milling, and grinding the mandrel to the required dimensions and tolerances.

- Ensuring precise concentricity and surface finish.

Heat Treatment

- Hardening or tempering the mandrel to achieve the desired properties, such as strength or wear resistance.

Coating

- Applying protective or anti-friction coatings to enhance the mandrel’s performance and durability.

3. What factors should be considered when choosing a mandrel for a specific application?

- Workpiece material and shape.

- Required accuracy and tolerances.

- Mandrel material and dimensions.

- Machining operation and cutting forces.

- Cost and availability.

4. Describe the different methods of mounting a mandrel on a machine tool.

- Using a threaded nose.

- Attaching to a drawbar.

- Clamping onto a collet.

- Inserting into a spindle taper.

5. What are the common causes of mandrel failure?

- Excessive wear or damage due to improper use or maintenance.

- Vibration and resonance issues.

- Corrosion or chemical reactions.

- Fatigue or stress fractures.

6. How do you inspect and maintain a mandrel to ensure its accuracy and performance?

- Regularly cleaning and lubricating the mandrel.

- Inspecting for wear, damage, or corrosion.

- Measuring concentricity and surface finish using precision instruments.

- Re-grinding or honing the mandrel when necessary.

7. What are the latest advancements in mandrel technology?

- Use of innovative materials such as carbon fiber composites.

- Development of self-centering and quick-release mandrels.

- Integration of sensors for monitoring mandrel performance.

- Advanced manufacturing techniques for improved precision and efficiency.

8. How do you stay up-to-date with the latest mandrel making technologies and techniques?

- Attending industry trade shows and conferences.

- Reading technical journals and articles.

- Networking with other professionals in the field.

- Participating in training and certification programs.

9. What are the safety precautions that must be taken when working with mandrels?

- Wearing appropriate safety gear.

- Ensuring proper mounting and alignment of the mandrel.

- Avoiding overloading or excessive force on the mandrel.

- Inspecting the mandrel regularly for any defects or damage.

10. Do you have any experience in using or designing specialty mandrels for unique applications?

Provide specific examples of your work and highlight your problem-solving abilities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mandrel Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mandrel Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mandrel Makers are responsible for the production and maintenance of mandrels, which are essential components in the manufacturing of various products. Their key job responsibilities include:

1. Mandrel Production:

Creating mandrels from raw materials such as wood, metal, or plastic

- Utilizing specialized machinery and tools to shape and assemble mandrels

- Ensuring dimensional accuracy and meeting precise specifications

2. Mandrel Maintenance:

Inspecting and repairing existing mandrels to maintain their functionality

- Identifying and addressing wear and tear, corrosion, or damage

- Performing routine maintenance tasks, such as cleaning, lubrication, and alignment

3. Quality Control:

Verifying the quality of mandrels before they are released for use

- Conducting visual inspections, dimensional measurements, and functional tests

- Ensuring compliance with industry standards and customer specifications

4. Process Improvement:

Identifying opportunities to enhance mandrel production and maintenance processes

- Adopting new techniques, technologies, or materials to increase efficiency and accuracy

- Implementing cost-saving measures and reducing waste by optimizing material usage

Interview Tips

To ace the interview for the Mandrel Maker position, follow these tips and preparation strategies:

1. Research the Company and Industry:

Familiarize yourself with the company’s products, services, and industry trends.

- Visit the company’s website and LinkedIn page.

- Research industry publications and news articles.

2. Practice Common Interview Questions:

Prepare for typical interview questions, such as:

- “Tell me about your experience in mandrel making.”

- “How do you ensure the quality of your mandrels?”

Example Outline:

- Start with a brief introduction of your experience and skills.

- Highlight specific examples of how you successfully produced or maintained mandrels.

- Quantify your results whenever possible, using metrics such as production rates or quality improvement percentages.

3. Highlight Your Technical Abilities:

Emphasize your knowledge of mandrel design, manufacturing, and maintenance techniques.

- Describe your proficiency in using specialized machinery and tools.

- Explain your understanding of materials and their suitability for different mandrel applications.

4. Showcase Your Problem-Solving Skills:

Provide examples of how you have identified and resolved issues related to mandrel production or maintenance.

- Describe a situation where you encountered a problem and explain the steps you took to find a solution.

- Highlight your ability to think critically and apply your technical knowledge to solve complex problems.

5. Prepare Questions for the Interviewer:

Preparing thoughtful questions demonstrates your interest in the position and the company.

- Ask about the company’s current projects and future plans.

- Inquire about the challenges and opportunities within the mandrel maker role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Mandrel Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Mandrel Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.