Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mangle Roll Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

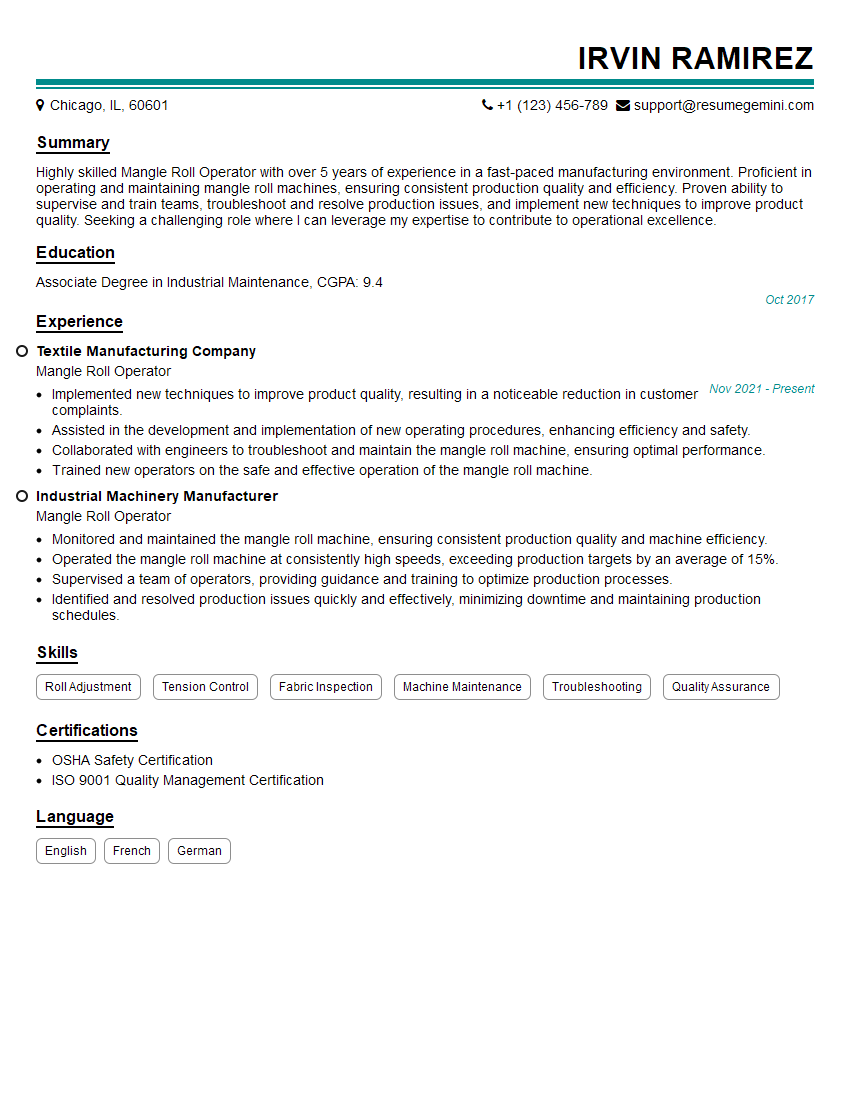

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mangle Roll Operator

1. Describe the primary responsibilities of a Mangle Roll Operator.

As a Mangle Roll Operator, my key responsibilities include:

- Operating and maintaining mangle rolls to smooth and finish textiles

- Adjusting machine settings to achieve desired fabric properties

- Inspecting fabrics for defects and ensuring quality standards are met

- Troubleshooting machine malfunctions and performing minor repairs

- Maintaining a clean and safe work area

2. What are the different types of mangle rolls and their uses?

There are several types of mangle rolls used in textile finishing, each with specific applications:

a. Friction Mangle Rolls:

- Generate friction to create heat and smooth fabrics

- Used for finishing woven and knitted fabrics

b. Calender Mangle Rolls:

- Use pressure and heat to impart a glossy or matte finish

- Suitable for finishing delicate fabrics such as silk and lace

c. Embossing Mangle Rolls:

- Impress patterns or designs onto fabrics

- Used for creating decorative effects on textiles

3. Explain the process of setting up a mangle roll machine.

The setup process involves the following steps:

- Inspecting the machine and ensuring it is in good working order

- Loading the fabric into the machine and threading it through the rollers

- Adjusting machine settings, such as temperature, pressure, and speed

- Running a test batch to ensure the desired fabric properties are achieved

- Calibrating the machine to maintain consistent results

4. How do you troubleshoot common problems encountered in mangle roll operations?

Common problems and troubleshooting steps include:

- Fabric wrinkles: Adjust machine settings, check fabric tension, and ensure rollers are aligned

- Fabric tears: Inspect rollers for damage, adjust machine settings, and ensure fabric is fed smoothly

- Uneven finish: Check machine alignment, adjust pressure settings, and ensure rollers are heated evenly

- Defective patterns: Clean embossing rollers, check temperature settings, and adjust machine speed

5. Describe the safety precautions that must be followed when operating mangle rolls.

To ensure safety, I adhere to the following precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs

- Never place hands or fingers near moving parts

- Keep the work area clean and free of tripping hazards

- Report any machine malfunctions or safety concerns immediately

- Follow lockout/tagout procedures when performing maintenance or repairs

6. How do you maintain the quality of fabrics processed through mangle rolls?

To maintain fabric quality, I:

- Inspect fabrics before and after processing

- Adjust machine settings to achieve the desired finish

- Monitor fabric temperature to prevent damage

- Clean and maintain rollers regularly to ensure smooth operation

- Keep records of machine settings and fabric properties to ensure consistency

7. Explain how you work as part of a team in a textile production environment.

In a team environment:

- I communicate effectively with colleagues to ensure smooth production

- Share knowledge and assist others with troubleshooting

- Contribute to team discussions and decision-making

- Maintain a positive and collaborative attitude

- Support the team in achieving production goals and quality standards

8. Describe your experience in using statistical process control (SPC) techniques.

I have experience in using SPC techniques to monitor and improve mangle roll operations:

- Collecting data on machine settings, fabric properties, and production rates

- Creating control charts to track process performance

- Analyzing data to identify trends and deviations

- Making adjustments to machine settings and processes to improve quality

- Using SPC to continuously improve efficiency and reduce defects

9. What is your approach to staying up-to-date with the latest technologies and techniques in mangle roll operations?

I am committed to continuous learning and staying abreast of industry advancements:

- Attending industry conferences and workshops

- Reading technical journals and publications

- Participating in online training programs

- Seeking feedback from experienced professionals

- Exploring new technologies and evaluating their potential benefits

10. How do you handle high-volume production demands while maintaining quality standards?

To handle high-volume demands efficiently:

- I optimize machine settings and processes for maximum throughput

- Ensure regular maintenance and calibration to minimize downtime

- Prioritize tasks and delegate responsibilities effectively

- Monitor fabric quality throughout the process and make adjustments as needed

- Collaborate with the team to identify and address bottlenecks

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mangle Roll Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mangle Roll Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mangle Roll Operators are responsible for the efficient and safe operation of mangle rolls, which are used to iron and finish fabrics in textile manufacturing plants. Their key job responsibilities include:

1. Machine Operation

Operate mangle rolls to iron and finish fabrics according to specified requirements.

- Load and unload fabrics into and from the mangle roll.

- Adjust machine settings such as temperature, pressure, and speed to achieve desired results.

2. Fabric Quality Control

Inspect fabrics before and after processing to ensure quality and identify any defects.

- Check fabrics for wrinkles, creases, or other imperfections.

- Report any quality issues to supervisors or maintenance personnel.

3. Maintenance and Troubleshooting

Perform basic maintenance and troubleshooting tasks to keep mangle rolls in good working condition.

- Clean and lubricate machine parts.

- Identify and resolve minor malfunctions.

4. Safety and Compliance

Follow established safety procedures and wear appropriate personal protective equipment (PPE) while operating mangle rolls.

- Ensure that all machine guards and safety devices are in place and functioning properly.

- Comply with all applicable safety regulations and standards.

Interview Tips

To ace the interview for a Mangle Roll Operator position, candidates should prepare thoroughly and demonstrate their understanding of the job responsibilities and industry knowledge. Here are some interview tips and preparation hacks:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and culture. Research the textile manufacturing industry to understand its processes and challenges.

2. Practice Common Interview Questions

Anticipate questions related to your mangle roll operating experience, fabric quality control techniques, and safety protocols. Prepare concise and specific answers that showcase your skills and knowledge.

3. Highlight Relevant Experience

Emphasize your past experience in operating mangle rolls or similar machinery. Quantify your accomplishments and provide specific examples of your contributions.

4. Demonstrate Technical Knowledge

Discuss your understanding of mangle roll mechanics, fabric types, and finishing techniques. Be prepared to answer questions about machine settings, troubleshooting, and maintenance procedures.

5. Prepare Questions for the Interviewer

Asking thoughtful questions shows interest and engagement. Prepare questions about the company’s operations, safety standards, or future plans.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mangle Roll Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.