Are you gearing up for a career in Manifold Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Manifold Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

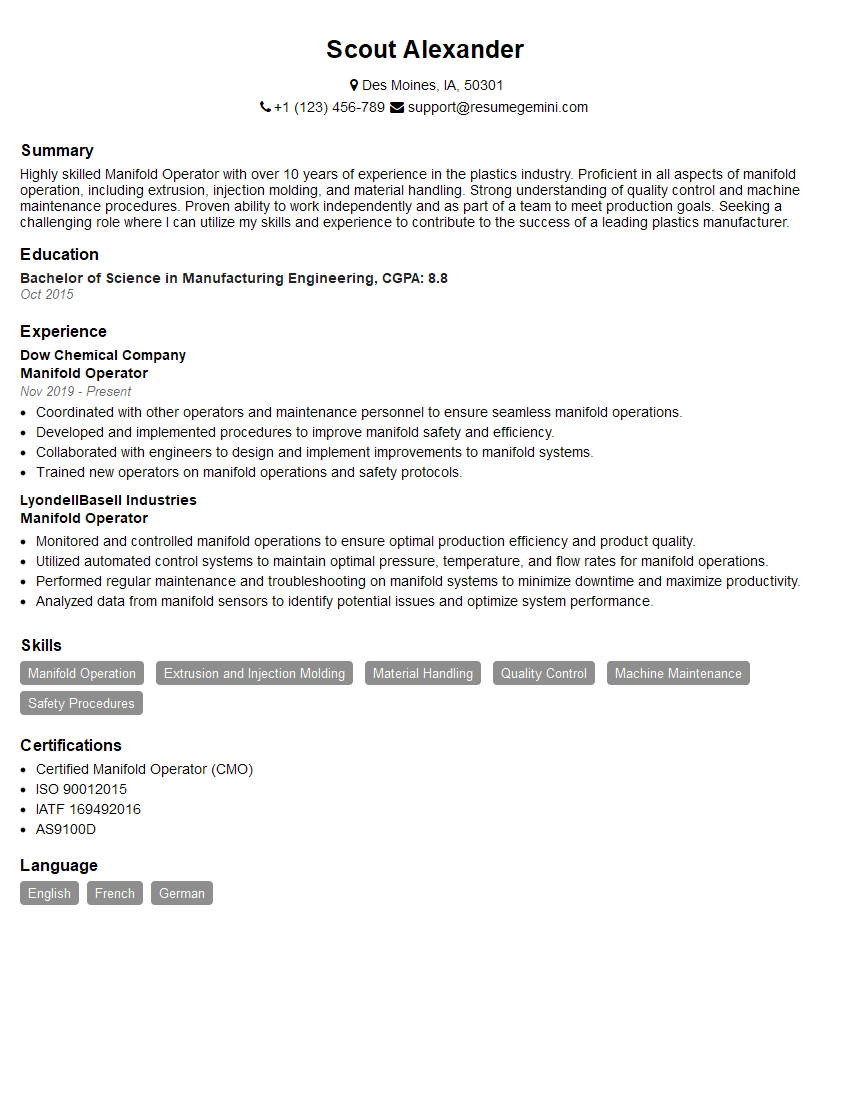

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Manifold Operator

1. Describe the key responsibilities and duties of a Manifold Operator?

The key responsibilities and duties of a Manifold Operator include:

- Monitoring and controlling the flow of fluids and gases through pipelines and manifolds.

- Operating and maintaining valves, pumps, and other equipment used in the manifold system.

- Ensuring that the manifold system is operating safely and efficiently.

- Responding to alarms and emergencies.

- Performing routine maintenance and repairs on the manifold system.

2. What are the different types of manifolds used in the oil and gas industry?

Onshore manifolds

- Gathering manifolds: These manifolds collect production from multiple wells and route it to a central processing facility.

- Distribution manifolds: These manifolds distribute fluids and gases to different parts of a facility or to end users.

Offshore manifolds

- Production manifolds: These manifolds collect production from subsea wells and route it to a platform or FPSO.

- Injection manifolds: These manifolds inject fluids or gases into subsea reservoirs for enhanced oil recovery or other purposes.

3. What are the different types of valves used in manifold systems?

The different types of valves used in manifold systems include:

- Gate valves

- Globe valves

- Check valves

- Ball valves

- Butterfly valves

4. What are the different types of pumps used in manifold systems?

The different types of pumps used in manifold systems include:

- Centrifugal pumps

- Reciprocating pumps

- Screw pumps

- Turbine pumps

5. What are the different types of instrumentation used in manifold systems?

The different types of instrumentation used in manifold systems include:

- Pressure gauges

- Temperature gauges

- Flow meters

- Level sensors

- Safety valves

6. What are the different types of maintenance tasks performed on manifold systems?

The different types of maintenance tasks performed on manifold systems include:

- Routine inspections

- Valve maintenance

- Pump maintenance

- Instrumentation maintenance

- Overhaul and repair

7. What are the different types of emergencies that can occur in manifold systems?

The different types of emergencies that can occur in manifold systems include:

- Leaks

- Fires

- Explosions

- Equipment failures

- Human error

8. What are the different types of safety procedures that must be followed when working on manifold systems?

The different types of safety procedures that must be followed when working on manifold systems include:

- Lockout/tagout procedures

- Personal protective equipment (PPE)

- Emergency response procedures

9. What are the different types of training required for Manifold Operators?

The different types of training required for Manifold Operators include:

- Safety training

- Equipment training

- Process training

- Emergency response training

10. What are the career advancement opportunities for Manifold Operators?

The career advancement opportunities for Manifold Operators include:

- Lead Operator

- Supervisor

- Manager

- Engineer

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Manifold Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Manifold Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Manifold Operators play a critical role in the manufacturing industry by ensuring the smooth and efficient operation of manifold systems. Their responsibilities encompass a variety of tasks that contribute to the production process.

1. Manifold Operation and Control

One of the primary responsibilities of a Manifold Operator is to operate and control the manifold system. This involves understanding the system’s functions, monitoring its performance, and making necessary adjustments to ensure optimal flow and pressure.

- Monitoring and adjusting manifold pressure and flow rates

- Operating valves and switches to control fluid flow

2. System Maintenance and Troubleshooting

Manifold Operators are responsible for maintaining the manifold system and troubleshooting any issues that may arise. This requires regular inspections, preventive maintenance, and quick response to any malfunctions or leaks.

- Performing scheduled maintenance and inspections

- Identifying and resolving system malfunctions

- Coordinating with maintenance personnel for repairs

3. Documentation and Record Keeping

Manifold Operators are required to maintain accurate documentation of the manifold system’s operations and maintenance. This includes keeping logbooks, recording system parameters, and documenting any repairs or modifications.

- Maintaining logbooks and records of system operations

- Recording system settings and adjustments

- Documenting maintenance activities and repairs

4. Safety and Compliance

Manifold Operators must prioritize the safety of themselves and others while working with high-pressure fluids. They are responsible for adhering to safety regulations and ensuring that the manifold system is operated in a safe and compliant manner.

- Following established safety protocols

- Identifying and mitigating potential hazards

- Reporting any accidents or near-misses

Interview Tips

Preparing for an interview for a Manifold Operator position requires a combination of technical knowledge and a strong understanding of the industry. Here are some tips and strategies to help you ace the interview:

1. Research the Company and the Position

Before the interview, thoroughly research the company and the specific Manifold Operator position. This will demonstrate your interest in the role and your knowledge of the company’s operations. Familiarize yourself with the company’s website, industry news, and any relevant projects or initiatives.

- Check the company’s website for mission, values, and recent news

- Read industry publications to stay up-to-date on trends and best practices

- Prepare questions specific to the position and the company’s operations

2. Highlight Your Technical Skills and Experience

During the interview, emphasize your technical skills and experience in operating and maintaining manifold systems. Quantify your accomplishments whenever possible, using specific examples to demonstrate your proficiency in the field. Discuss your knowledge of different types of manifolds, flow control, and troubleshooting techniques.

- Provide examples of complex manifold systems you have operated or maintained

- Describe how you have handled and resolved system malfunctions in the past

- Mention any certifications or training programs you have completed

3. Show Your Safety Awareness and Compliance Knowledge

Safety is paramount in any manufacturing environment, especially when working with high-pressure fluids. Highlight your safety awareness and understanding of industry regulations. Explain how you prioritize safety in your work and demonstrate your knowledge of lockout/tagout procedures, personal protective equipment (PPE), and emergency response protocols.

- Discuss your experience with safety audits and inspections

- Explain your understanding of relevant industry standards and regulations

- Provide examples of how you have implemented safety measures in your previous roles

4. Prepare for Common Interview Questions

Practice answering common interview questions related to your experience, skills, and motivations. Here are some examples of questions you may encounter:

- Tell me about your experience in operating and maintaining manifold systems.

- Describe a time when you had to troubleshoot a complex manifold issue.

- How do you prioritize safety when working with high-pressure fluids?

- What is your understanding of industry regulations and standards related to manifold systems?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Manifold Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.