Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Manual Lathe Machinist interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Manual Lathe Machinist so you can tailor your answers to impress potential employers.

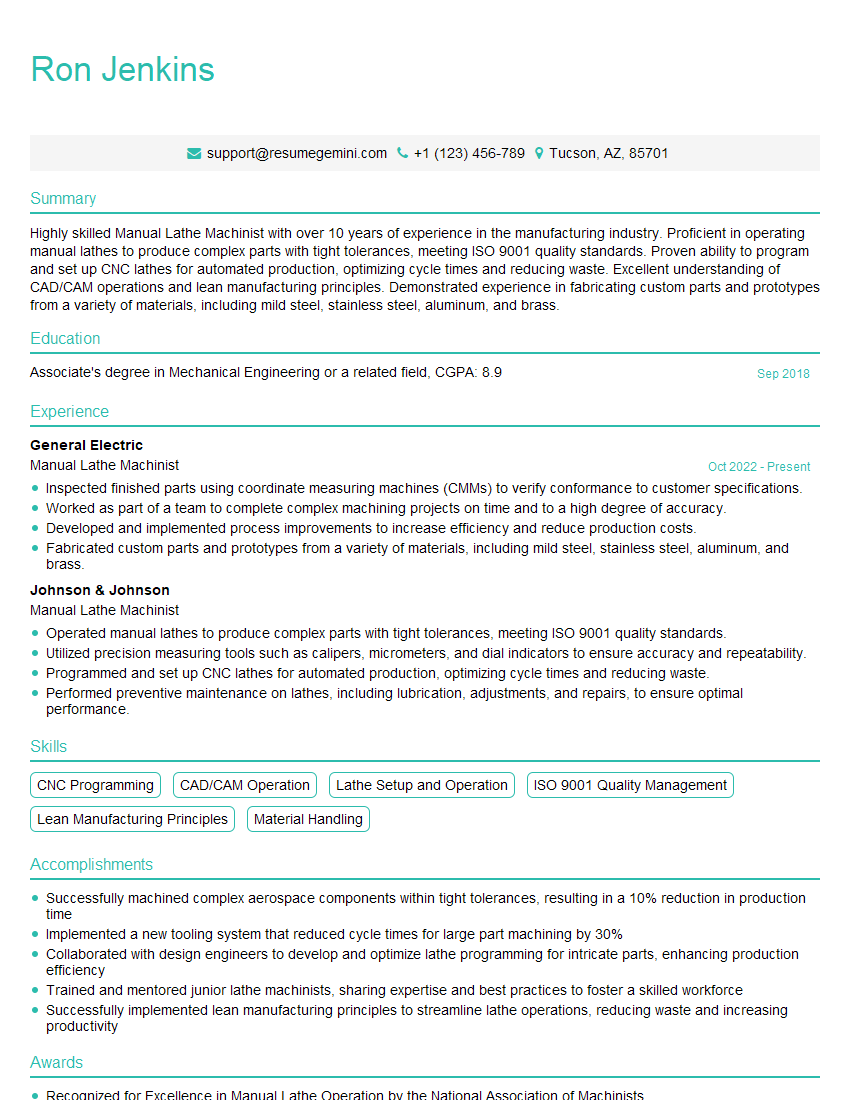

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Manual Lathe Machinist

1. Explain the different types of manual lathes and their applications?

- Engine lathe: The most common type of lathe, used for a wide range of operations, including turning, facing, boring, and threading.

- Turret lathe: A lathe with a rotating turret that holds multiple cutting tools, allowing for quick tool changes.

- Capstan lathe: A turret lathe with a vertical spindle, suitable for high-volume production.

- CNC lathe: A computer-controlled lathe that automates the cutting process, resulting in higher precision and efficiency.

2. Describe the process of setting up a manual lathe for a specific job?

Job planning

- Read and understand the blueprints.

- Select the appropriate materials and cutting tools.

- Calculate the cutting speeds and feeds.

Lathe setup

- Mount the workpiece in the chuck or collet.

- Set the cutting tool in the tool holder.

- Adjust the cutting depth and feed rate.

- Lubricate the cutting area.

3. What are the safety precautions that must be followed when operating a manual lathe?

- Wear appropriate safety gear, including eye protection, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Securely mount the workpiece and cutting tool.

- Never reach across the lathe while it is running.

- Be aware of the location of the emergency stop button.

4. How do you measure and inspect the accuracy of a machined part?

- Calipers: Used to measure the outside and inside diameters of a part.

- Micrometer: Used to measure the thickness of a part.

- Dial indicator: Used to measure the roundness and taper of a part.

5. What are the different types of cutting tools used in manual lathe operations?

- Turning tools: Used to create cylindrical surfaces.

- Facing tools: Used to create flat surfaces.

- Boring tools: Used to create holes in a workpiece.

- Threading tools: Used to create threads on a workpiece.

6. How do you calculate the cutting speed and feed rate for a specific material and cutting tool?

- Cutting speed: v = πDN/12, where v is the cutting speed in surface feet per minute, D is the diameter of the workpiece in inches, and N is the spindle speed in revolutions per minute.

- Feed rate: f = v/N, where f is the feed rate in inches per revolution.

7. What are the different types of coolants used in manual lathe operations and their advantages and disadvantages?

- Water-based coolants: Advantages: inexpensive, good cooling properties. Disadvantages: can cause rust and corrosion.

- Oil-based coolants: Advantages: good lubrication properties, can prevent rust and corrosion. Disadvantages: more expensive, can be difficult to dispose of.

- Synthetic coolants: Advantages: good cooling and lubrication properties, non-toxic. Disadvantages: more expensive.

8. How do you troubleshoot common problems encountered during manual lathe operations?

- Chatter: Caused by excessive vibration, can be reduced by using a sharper cutting tool, increasing the cutting speed, or reducing the feed rate.

- Tool breakage: Caused by using a dull cutting tool, excessive cutting forces, or improper tool geometry.

- Poor surface finish: Caused by using a dull cutting tool, excessive cutting speed, or improper lubrication.

9. What is the difference between a manual lathe and a CNC lathe?

- Manual lathe: Operated by hand, requires skilled operators.

- CNC lathe: Computer-controlled, can produce complex parts with high precision and repeatability.

10. What are the advantages of using a CNC lathe over a manual lathe?

- Higher precision: CNC lathes can achieve higher precision than manual lathes due to their computer-controlled operation.

- Increased efficiency: CNC lathes can run unattended, reducing labor costs.

- Reduced scrap: CNC lathes are less likely to produce scrap parts due to their high precision and repeatability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Manual Lathe Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Manual Lathe Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Manual Lathe Machinist plays a pivotal role in shaping and refining metal components using a manual lathe, ensuring precision and accuracy in the final product.

1. Preparing Workpieces

A machinist’s journey begins with carefully preparing the workpiece. This involves selecting the appropriate raw material, clamping it securely on the lathe, and aligning it to the desired specifications.

2. Operating and Controlling Lathe

With the workpiece in place, the machinist skillfully operates the lathe, maneuvering cutting tools with precision. They adjust cutting speeds, feed rates, and tool depths based on the workpiece material and desired finish.

3. Monitoring and Inspecting

Throughout the machining process, a keen eye is kept on the workpiece, ensuring that it meets the required dimensions and tolerances. Regular inspections are conducted using measuring instruments such as calipers, micrometers, and gauges.

4. Maintaining Equipment

To guarantee optimal performance and accuracy, a machinist diligently maintains the lathe and its tooling. This includes regular cleaning, lubrication, and calibration to ensure the equipment is always in top condition.

5. Reading Blueprints and Drawings

A strong understanding of blueprints and technical drawings is essential for a machinist. These documents provide the instructions for creating the desired part, and the machinist must interpret them accurately to achieve the required specifications.

Interview Tips

Preparation and confidence are key ingredients for a successful job interview. Here are some tips to help you ace your interview for a Manual Lathe Machinist position:

1. Research the Company and Role

Spend some time learning about the company and the specific role you’re applying for. Understand the company’s industry, products, services, and culture. This knowledge will help you demonstrate your interest and enthusiasm.

2. Practice Your Answers

It’s natural to feel nervous during an interview, but practicing your answers to common questions can boost your confidence and help you articulate your skills effectively.

3. Showcase Your Skills

Highlight your technical abilities as a machinist, including your experience with different types of lathes, cutting tools, and measurement equipment. Quantify your accomplishments whenever possible.

4. Emphasize Safety and Quality

In this industry, safety and quality are paramount. Demonstrate your commitment to these aspects by explaining how you ensure a safe work environment and produce high-quality work.

5. Prepare Questions

At the end of the interview, take the opportunity to ask thoughtful questions about the role, the company, and the industry. This shows your engagement and interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Manual Lathe Machinist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!