Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Manual Winder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Manual Winder so you can tailor your answers to impress potential employers.

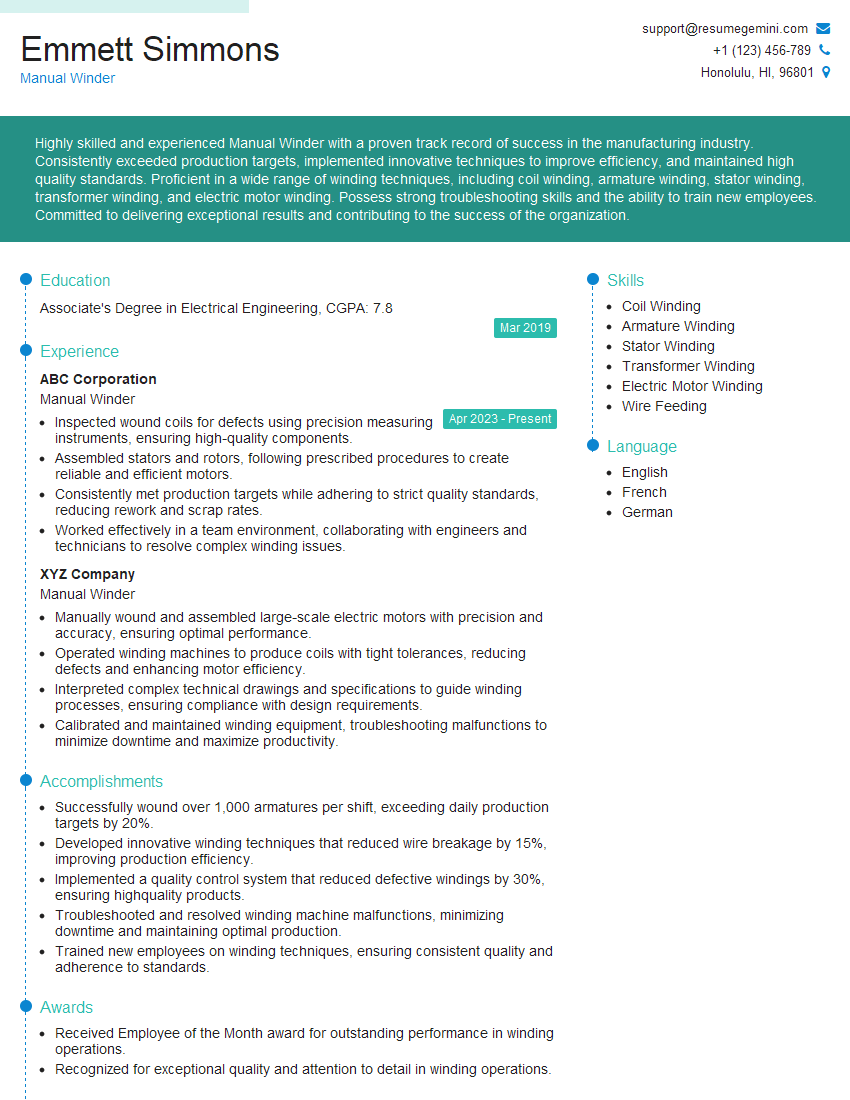

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Manual Winder

1. Describe the most important characteristics of a Manual Winder?

The most important characteristics of a Manual Winder are:

- Attention to detail: Manual Winders must be able to pay close attention to detail in order to ensure that the coils are wound correctly.

- Dexterity: Manual Winders must have good dexterity in order to handle the small wires and coils.

- Patience: Manual Winders must be patient, as the winding process can be time-consuming.

2. Explain the steps involved in manually winding a coil?

Inserting the wire into the coil former

- Select the correct wire gauge and insulation for the application.

- Cut the wire to the desired length.

- Insert the wire into the coil former, making sure that the wire is taut.

Winding the coil

- Wind the wire around the coil former, using a consistent tension.

- Keep the turns close together, but do not overlap them.

- Make sure that the wire is wound in the correct direction.

Finishing the coil

- Once the coil is wound, secure the ends of the wire.

- Insulate the coil if necessary.

- Test the coil to make sure that it is functioning properly.

3. What are the different types of coil winding machines?

The different types of coil winding machines include:

- Manual coil winding machines: These machines are operated by hand, and the operator must manually wind the wire around the coil former.

- Semi-automatic coil winding machines: These machines are partially automated, and the operator only needs to load the wire and start the machine. The machine will then automatically wind the wire around the coil former.

- Automatic coil winding machines: These machines are fully automated, and the operator only needs to load the wire and set the machine. The machine will then automatically wind the wire around the coil former and finish the coil.

4. What are the advantages and disadvantages of using a manual coil winding machine?

Advantages

- Lower cost: Manual coil winding machines are less expensive than semi-automatic or automatic coil winding machines.

- More flexibility: Manual coil winding machines can be used to wind a wider variety of coils than semi-automatic or automatic coil winding machines.

- Easier to operate: Manual coil winding machines are easier to operate than semi-automatic or automatic coil winding machines.

Disadvantages

- Slower: Manual coil winding machines are slower than semi-automatic or automatic coil winding machines.

- More labor-intensive: Manual coil winding machines require more labor than semi-automatic or automatic coil winding machines.

- Less consistent: Manual coil winding machines can produce less consistent coils than semi-automatic or automatic coil winding machines.

5. What are the challenges of manually winding a coil?

The challenges of manually winding a coil include:

- Ensuring that the wire is wound correctly: If the wire is not wound correctly, the coil will not function properly.

- Maintaining a consistent tension: If the tension is too loose, the wire will not be wound tightly enough and the coil will be weak. If the tension is too tight, the wire will break.

- Keeping the turns close together: If the turns are too far apart, the coil will not be as efficient.

- Avoiding overlapping the turns: If the turns overlap, the coil will be short-circuited.

6. What are the different types of coils that can be wound manually?

The different types of coils that can be wound manually include:

- Inductors: Inductors are used to store energy in a magnetic field.

- Transformers: Transformers are used to transfer energy from one circuit to another.

- Relays: Relays are used to control the flow of electricity in a circuit.

- Solenoids: Solenoids are used to create a magnetic field when an electric current is passed through them.

7. What are the safety precautions that must be taken when manually winding a coil?

The safety precautions that must be taken when manually winding a coil include:

- Wear safety glasses: Safety glasses protect your eyes from flying debris.

- Wear gloves: Gloves protect your hands from cuts and abrasions.

- Use a well-ventilated area: The fumes from the solder can be harmful if inhaled.

- Do not touch the coil while it is energized: The coil can carry a high voltage, which can be dangerous.

8. What are the quality control checks that must be performed on a manually wound coil?

The quality control checks that must be performed on a manually wound coil include:

- Visual inspection: The coil should be visually inspected for any defects, such as loose wires or overlapping turns.

- Electrical testing: The coil should be electrically tested to ensure that it is functioning properly.

- Mechanical testing: The coil should be mechanically tested to ensure that it is able to withstand the stresses of the application.

9. What are the maintenance procedures that must be performed on a manual coil winding machine?

The maintenance procedures that must be performed on a manual coil winding machine include:

- Clean the machine regularly: The machine should be cleaned regularly to remove any dirt or debris.

- Lubricate the machine regularly: The machine should be lubricated regularly to ensure that it is functioning properly.

- Inspect the machine regularly: The machine should be inspected regularly for any signs of wear or damage.

10. What are the troubleshooting tips for a manual coil winding machine?

The troubleshooting tips for a manual coil winding machine include:

- If the wire is not winding correctly, check the tension and the direction of the wind.

- If the coil is not functioning properly, check the electrical connections.

- If the machine is making a noise, check the bearings and the gears.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Manual Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Manual Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Manual winders are responsible for the assembly and maintenance of electric motors and other electrical components. They use a variety of hand tools and machines to wind wire around coils and other electrical components. Manual winders must have a good understanding of electrical principles and be able to work independently.

1. Assemble electrical components

Manual winders assemble electrical components by hand, using a variety of tools and machines. They must be able to read and understand blueprints and schematics, and they must be able to work with precision and accuracy.

- Wind wire around coils

- Insulate coils

- Solder connections

2. Maintain electrical components

Manual winders also maintain electrical components by cleaning, inspecting, and repairing them. They must be able to troubleshoot problems and make repairs quickly and efficiently.

- Clean electrical components

- Inspect electrical components for damage

- Repair electrical components

3. Test electrical components

Manual winders test electrical components to ensure that they are functioning properly. They use a variety of test equipment to check for continuity, resistance, and other electrical properties.

- Test electrical components for continuity

- Test electrical components for resistance

- Test electrical components for other electrical properties

4. Keep a clean and organized work area

Manual winders must keep their work area clean and organized in order to maintain safety and efficiency. They must be able to find tools and materials quickly and easily, and they must be able to clean up spills and other messes.

- Keep work area clean and organized

- Find tools and materials quickly and easily

- Clean up spills and other messes

Interview Tips

Here are some tips to help you ace your interview for a manual winder position:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also help you answer questions about your qualifications and experience.

- Visit the company’s website

- Read the job description

- Talk to people who work at the company

2. Prepare your answers to common interview questions

There are a few common interview questions that you are likely to be asked in an interview for a manual winder position. These questions include:

- Tell me about your experience as a manual winder.

- What are your strengths and weaknesses as a manual winder?

- Why are you interested in this position?

Take some time to prepare your answers to these questions in advance. This will help you feel more confident and prepared during your interview.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the position.

4. Be enthusiastic and positive

During your interview, it is important to be enthusiastic and positive. This will show the interviewer that you are excited about the possibility of working for the company. It is also important to be positive about your skills and experience. This will help the interviewer see that you are confident in your abilities.

5. Ask questions

At the end of your interview, be sure to ask the interviewer questions. This shows the interviewer that you are interested in the position and that you are eager to learn more about the company. It is also a good way to get more information about the position and the company.

- What are the biggest challenges facing the company?

- What are the company’s goals for the future?

- What is the company culture like?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Manual Winder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Manual Winder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.