Are you gearing up for an interview for a Manufacturing Coordinator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Manufacturing Coordinator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

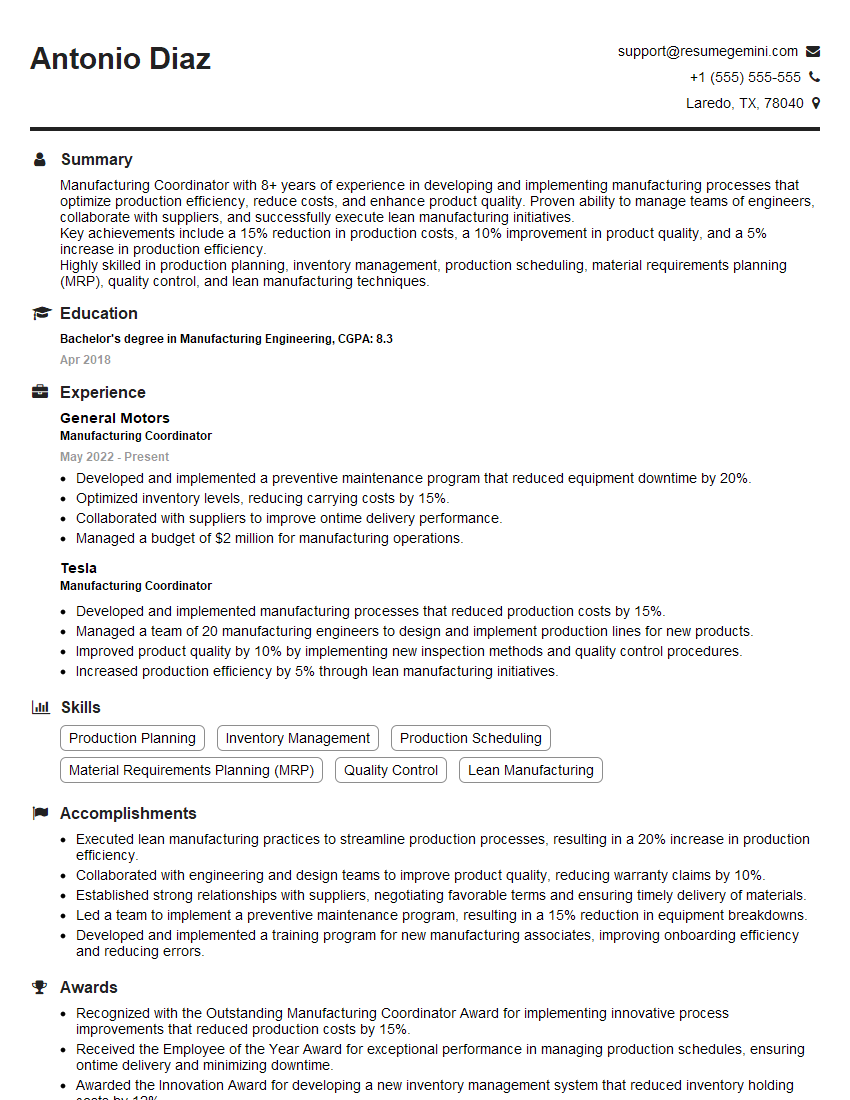

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Manufacturing Coordinator

1. Explain the role of a Manufacturing Coordinator?

The Manufacturing Coordinator is responsible for coordinating and overseeing the production process in a manufacturing facility. They work with various departments to ensure that all aspects of production are running smoothly and efficiently. Key responsibilities include:

- Planning and scheduling production

- Managing inventory and materials

- Coordinating with suppliers and vendors

- Monitoring production and quality

- Resolving production issues and bottlenecks

- Reporting on production performance

2. Describe the key skills and qualifications required to be a successful Manufacturing Coordinator?

Technical Skills

- Excellent understanding of manufacturing processes

- Proficient in production planning and scheduling software

- Strong knowledge of inventory management principles

- Experience with quality control and inspection techniques

Soft Skills

- Strong communication and interpersonal skills

- Ability to work independently and as part of a team

- Problem-solving and decision-making skills

- Attention to detail and accuracy

3. How do you manage inventory and materials to ensure smooth production?

Effective inventory management is crucial for smooth production. I utilize various techniques, including:

- Implementing inventory control systems

- Conducting regular inventory audits

- Establishing safety stock levels

- Collaborating with suppliers for timely deliveries

- Monitoring inventory levels and adjusting orders as needed

4. Describe your approach to coordinating with suppliers and vendors?

Building strong relationships with suppliers and vendors is essential. I focus on:

- Clear and regular communication

- Establishing performance expectations

- Monitoring supplier performance and providing feedback

- Negotiating favorable terms and conditions

- Identifying and qualifying new suppliers as needed

5. How do you monitor production and quality to ensure that products meet specifications?

Production and quality monitoring are vital. I utilize:

- Regular production reports and dashboards

- Quality control inspections at various stages of production

- Statistical process control techniques

- Employee training and empowerment for quality assurance

- Corrective and preventive actions to address quality issues

6. Describe your experience in resolving production issues and bottlenecks?

Production issues are inevitable, and I address them with:

- Identifying the root cause of the issue

- Developing and implementing corrective actions

- Monitoring the effectiveness of solutions

- Collaborating with cross-functional teams to find solutions

- Documenting lessons learned to prevent recurrence

7. How do you report on production performance and identify areas for improvement?

Regular reporting and analysis are critical. I:

- Generate production performance reports

- Compare actual performance to targets

- Identify areas for improvement and develop action plans

- Communicate performance results to stakeholders

- Use data analysis tools to identify trends and patterns

8. Describe your experience in using manufacturing software and tools?

Proficiency in manufacturing software is essential. I have experience with:

- Production planning and scheduling software (e.g., ERP, MES)

- Inventory management systems

- Quality control software

- Statistical process control tools

- Data analysis and reporting tools

9. How do you stay updated on industry trends and best practices?

Continuous learning is important. I stay updated through:

- Attending industry events and conferences

- Reading industry publications and research papers

- Participating in online forums and webinars

- Networking with professionals in the field

- Seeking opportunities for professional development

10. What is your experience in implementing Lean Manufacturing principles?

Lean Manufacturing principles are valuable for optimizing production. I have experience in:

- Identifying and eliminating waste

- Improving production flow

- Reducing lead times

- Empowering employees for continuous improvement

- Monitoring and measuring Lean initiatives

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Manufacturing Coordinator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Manufacturing Coordinator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Manufacturing Coordinators play a pivotal role in optimizing production processes and ensuring the smooth flow of operations within manufacturing facilities. Their primary responsibilities include:

1. Master Production Schedule (MPS) Management

Developing and maintaining the MPS, which outlines the production sequence, timing, and quantities of products to be manufactured.

- Collaborate with production planning and engineering teams to determine production schedules.

- Analyze production data and identify bottlenecks or potential disruptions.

2. Material Procurement and Inventory Management

Coordinating and managing the procurement of raw materials, components, and supplies.

- Negotiate with suppliers and ensure timely delivery of materials.

- Monitor inventory levels and implement inventory control systems.

3. Production Process Monitoring and Control

Supervising and monitoring production processes to ensure efficiency and compliance with quality standards.

- Conduct regular inspections and identify production issues.

- Work with production teams to implement corrective actions and improve processes.

4. Quality Control and Assurance

Assisting with the implementation and maintenance of quality control systems.

- Monitor production processes and identify potential quality defects.

- Collaborate with quality assurance teams to resolve quality issues.

5. Cost Control and Optimization

Identifying and implementing cost-saving measures without compromising quality or production efficiency.

- Analyze production costs and identify areas for optimization.

- Negotiate with suppliers to secure competitive pricing.

Interview Tips

To ace the interview for a Manufacturing Coordinator position, it’s crucial to prepare thoroughly and demonstrate your skills and experience. Here are some tips and hacks to help you:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and manufacturing processes. Understand the specific responsibilities and requirements of the Manufacturing Coordinator role.

2. Highlight Your Experience and Skills

Emphasize your experience in production planning, inventory management, quality control, and cost optimization. Quantify your accomplishments and provide specific examples of how you improved efficiency or reduced costs.

3. Prepare for Technical Questions

Study basic manufacturing principles, such as material planning, production scheduling, and quality management. Be prepared to answer questions about your understanding of these concepts.

4. Ask Thoughtful Questions

Asking insightful questions during the interview shows your interest and engagement. Ask questions about the company’s growth strategy, production challenges, and opportunities for innovation.

5. Showcase Your Communication and Interpersonal Skills

Manufacturing Coordinators often interact with various departments and personnel. Demonstrate your ability to communicate effectively, build relationships, and work as part of a team.

Next Step:

Now that you’re armed with the knowledge of Manufacturing Coordinator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Manufacturing Coordinator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini