Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Manufacturing Engineering Technologist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

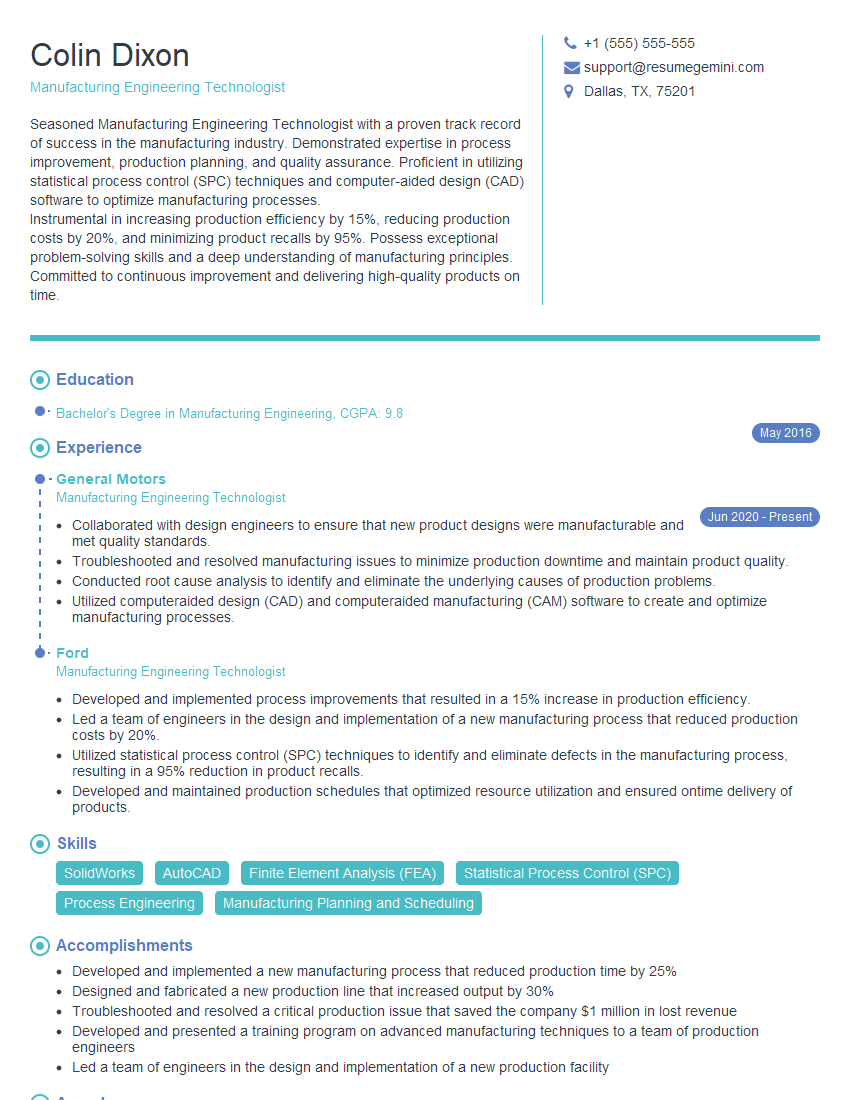

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Manufacturing Engineering Technologist

1. Explain the role of a Manufacturing Engineering Technologist in the product development process.

As a Manufacturing Engineering Technologist, I play a vital role in the product development process by:

- Collaborating with design engineers to ensure manufacturability of new products.

- Developing and optimizing manufacturing processes to achieve cost-effectiveness and quality.

- Supporting production operations by providing technical expertise and troubleshooting.

- Monitoring and analyzing production data to identify areas for improvement.

- Staying abreast of industry trends and advancements in manufacturing technology.

2. Describe the key principles of lean manufacturing and how you have applied them in your work.

Waste Reduction

- Eliminated unnecessary steps in production processes.

- Reduced inventory levels through just-in-time production.

Continuous Improvement

- Identified bottlenecks and developed solutions to enhance efficiency.

- Implemented standardized work instructions to reduce variability.

Employee Involvement

- Engaged production operators in process improvement initiatives.

- Empowered team members to make decisions and solve problems.

3. Discuss the importance of quality control in manufacturing and describe the methods you use to ensure product quality.

Quality control is paramount in manufacturing as it ensures:

- Customer satisfaction and product reliability.

- Reduced production costs and waste.

- Compliance with industry standards and regulations.

I employ the following methods to ensure product quality:

- Developing and implementing quality control plans.

- Performing inspections and tests at various stages of production.

- Analyzing data to identify quality trends and areas for improvement.

- Collaborating with suppliers to ensure the quality of incoming materials.

- Providing training to production personnel on quality standards.

4. Explain the process of developing and managing a bill of materials (BOM) for a complex manufacturing project.

- Gathering and organizing information on all components and materials required.

- Structuring the BOM hierarchically to reflect the assembly process.

- Assigning unique identifiers and descriptions to each item.

- Calculating quantities and lead times for each component.

- Managing changes and revisions to the BOM throughout the project.

- Collaborating with suppliers and cross-functional teams to ensure accuracy and availability.

5. Describe the different types of manufacturing processes and their advantages and disadvantages.

- Casting: Produces complex shapes with good surface finish, but can be costly and may require post-processing.

- Forging: Strengthens metal components, but can introduce defects and requires specialized equipment.

- Machining: Versatile process for creating precise parts, but can be time-consuming and generate waste.

- Additive Manufacturing (3D Printing): Allows for rapid prototyping and production of complex geometries, but may have limitations in material properties.

6. Explain the principles of statistical process control (SPC) and how you use it to monitor and improve manufacturing processes.

- Data Collection: Gather data on key process variables.

- Charting: Plot data on control charts to identify trends and patterns.

- Analysis: Determine if the process is in control or out of control.

- Corrective Action: Identify and implement changes to bring the process back into control.

By using SPC, I can:

- Reduce process variability and improve quality.

- Identify and eliminate sources of defects.

- Optimize process parameters to enhance efficiency.

7. Discuss the role of automation in manufacturing and its potential impact on the workforce.

- Advantages:

- Increased productivity and efficiency.

- Reduced labor costs and improved safety.

- Enhanced accuracy and consistency.

- Potential Impact on the Workforce:

- Displacement of routine tasks.

- Need for upskilling and reskilling.

- Creation of new jobs in areas such as automation engineering and maintenance.

8. Describe your experience in working with computer-aided design (CAD) and computer-aided manufacturing (CAM) software.

- Proficient in using CAD software (e.g., SolidWorks, AutoCAD) for 3D modeling and design.

- Skilled in generating toolpaths and NC code using CAM software (e.g., Mastercam, NX CAM) for CNC machining.

- Utilized these tools to optimize manufacturing processes, reduce design time, and improve product quality.

9. Explain the concept of tolerance analysis and its importance in manufacturing.

Tolerance analysis involves:

- Determining the acceptable range of variation for dimensions and tolerances on a product.

- Analyzing the impact of these variations on the overall performance and functionality of the product.

Its importance lies in:

- Ensuring proper fit and assembly of components.

- Preventing product failures due to dimensional errors.

- Optimizing manufacturing processes to minimize waste and rework.

10. Describe your approach to problem-solving and decision-making in a manufacturing environment.

- Define the problem: Gather data and clearly identify the root cause.

- Generate solutions: Brainstorm and evaluate multiple options.

- Analyze and select: Consider feasibility, cost, and potential impact.

- Implement and monitor: Execute the solution and track its effectiveness.

- Continuous improvement: Review and refine the solution based on outcomes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Manufacturing Engineering Technologist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Manufacturing Engineering Technologist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Manufacturing Engineering Technologist is responsible for various tasks that ensure efficient and effective manufacturing processes. Some of the key job responsibilities include:

1. Process Development and Improvement

Develop and optimize manufacturing processes to achieve desired product quality and cost targets.

- Design and implement new processes or improve existing ones.

- Conduct process analysis to identify and eliminate inefficiencies.

2. Equipment and Tooling Selection

Select and implement manufacturing equipment, tooling, and fixtures.

- Research and evaluate different equipment options.

- Determine the best tooling and fixtures for specific manufacturing tasks.

3. Production Planning and Scheduling

Collaborate with production planning and scheduling teams to ensure smooth and efficient manufacturing operations.

- Develop production plans and schedules.

- Monitor production progress and identify potential bottlenecks.

4. Quality Control and Inspection

Conduct quality control and inspection activities to ensure product quality.

- Develop and implement quality control procedures.

- Inspect products to ensure adherence to specifications.

Interview Tips

Preparing thoroughly can significantly increase your chances of success in a job interview. Here are some tips to help you ace your interview for a Manufacturing Engineering Technologist position:

1. Research the Company and Position

Take the time to learn about the company and the specific role you’re applying for. This will give you a better understanding of the company’s goals, values, and the requirements of the job.

- Visit the company’s website and social media pages.

- Read industry news and articles to gain insights into the company’s sector.

2. Practice Your Answers

Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” It’s also helpful to practice answering technical questions related to manufacturing engineering.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Provide specific examples of your skills and experience.

3. Highlight Your Technical Skills

Emphasize your knowledge of manufacturing processes, equipment, and tools. Be prepared to discuss your experience with quality control and inspection procedures.

- Mention any certifications or training programs you have completed.

- Share examples of projects where you have applied your technical skills.

4. Showcase Your Problem-Solving Abilities

Manufacturing Engineering Technologists often need to solve complex problems. During the interview, be prepared to share examples of how you have identified and resolved manufacturing issues.

- Describe a time when you encountered a challenge and how you overcame it.

- Explain how you approach problem-solving in a systematic and analytical way.

5. Be Enthusiastic and Confident

Show the interviewer that you are passionate about manufacturing engineering and eager to contribute to the company’s success. Be confident in your abilities and demonstrate your enthusiasm for the role.

- Maintain a positive attitude throughout the interview.

- Ask thoughtful questions to show your interest in the company and the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Manufacturing Engineering Technologist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Manufacturing Engineering Technologist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.