Feeling lost in a sea of interview questions? Landed that dream interview for Manufacturing Production Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Manufacturing Production Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

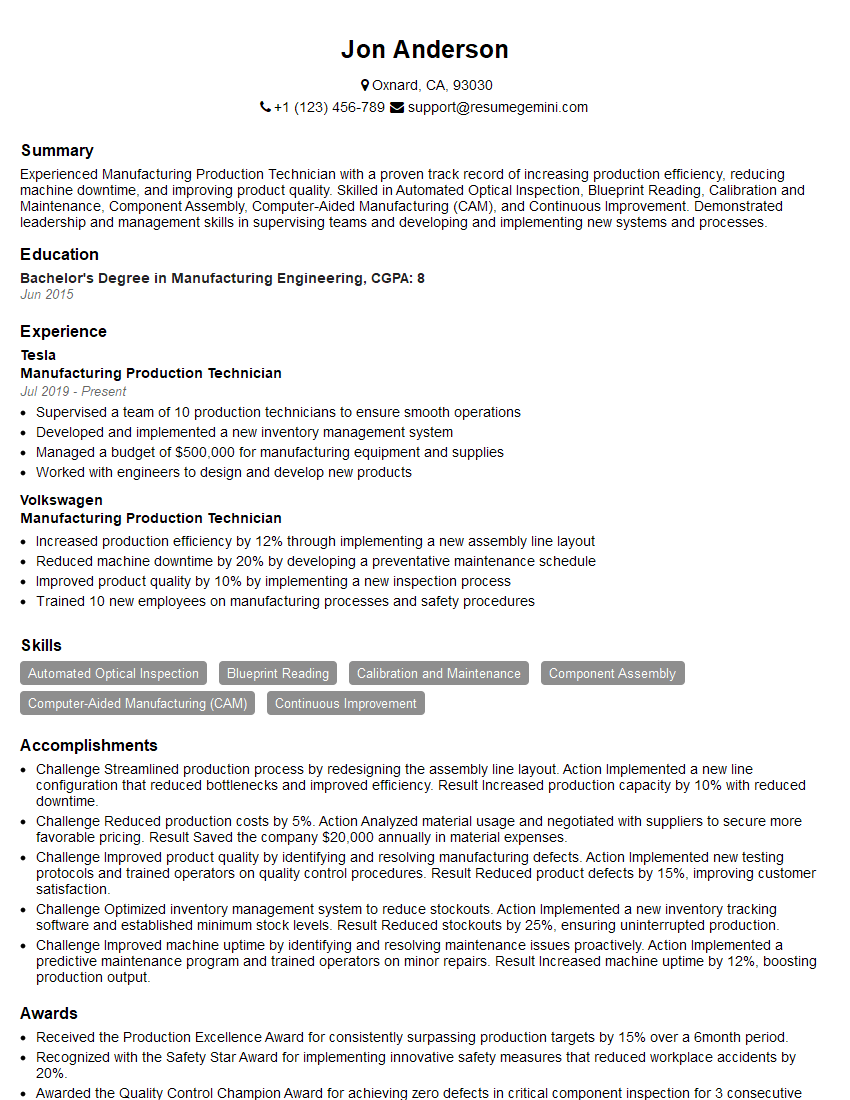

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Manufacturing Production Technician

1. How do you ensure the accuracy and precision of the equipment you use in the production process?

In my previous role as a Manufacturing Production Technician, I was responsible for ensuring the accuracy and precision of the equipment I used. I would perform regular calibration and maintenance checks on all equipment to ensure it was operating within specified tolerances. I would also use statistical process control (SPC) techniques to monitor the performance of the equipment and identify any potential issues. I have a strong understanding of the principles of metrology and can use a variety of measuring tools and techniques to ensure the accuracy and precision of measurements.

2. What are the different types of welding processes you have experience with? Which one is your favorite and why?

Gas Metal Arc Welding (GMAW)

- Experience with GMAW in various positions (flat, horizontal, vertical, overhead).

- Proficient in adjusting welding parameters (wire feed speed, voltage, travel speed) to achieve optimal weld quality.

Gas Tungsten Arc Welding (GTAW)

- Expertise in GTAW for precision welding and joining of thin materials.

- Skilled in shielding gas selection and torch manipulation techniques.

My Favorite: GTAW

- GTAW offers greater precision and control, resulting in high-quality welds.

- The ability to weld a wide range of materials, including stainless steel, aluminum, and titanium, makes it versatile.

3. How do you troubleshoot and solve problems when production equipment malfunctions?

- Follow established troubleshooting procedures to identify the root cause of the malfunction.

- Analyze error messages, consult technical manuals, and use diagnostic tools to pinpoint the issue.

- Apply problem-solving techniques to develop and implement effective solutions.

- Document the troubleshooting process and repair actions for future reference.

- Collaborate with maintenance technicians and engineers to resolve complex issues.

4. What are the key performance indicators (KPIs) you track to measure your productivity and efficiency as a Manufacturing Production Technician?

- Production output: Number of units produced per hour or shift.

- Quality rate: Percentage of products that meet quality standards.

- Machine uptime: Percentage of time that production equipment is operational.

- Downtime: Time spent on equipment maintenance, repairs, or changeovers.

- Cycle time: Time it takes to complete a production cycle.

- Material utilization: Percentage of raw materials used efficiently without waste.

5. Describe a time when you had to work as part of a team to solve a complex production problem. How did you contribute to the team’s success?

- Problem: A production line was experiencing frequent breakdowns due to a faulty sensor.

- Teamwork: Collaborated with maintenance technicians and engineers to diagnose the issue.

- My Contribution: Used my knowledge of the equipment’s electrical system to troubleshoot the sensor and identify the root cause.

- Outcome: Implemented a solution that eliminated the breakdowns and improved production efficiency.

6. What is your experience with lean manufacturing principles and how have you applied them in a production environment?

- 5S: Implemented 5S principles to improve workplace organization and efficiency.

- Kaizen: Continuously identified and implemented small improvements to reduce waste and increase productivity.

- Just-in-Time (JIT): Optimized inventory levels and reduced lead times to improve production flow.

- Total Productive Maintenance (TPM): Participated in TPM activities to ensure equipment reliability and minimize downtime.

7. How do you stay up-to-date with the latest advancements in manufacturing technology?

- Industry conferences and exhibitions: Attend industry events to learn about new technologies and best practices.

- Trade publications and online resources: Regularly read industry publications and online forums to stay informed.

- Training and certifications: Pursue training and certifications to enhance my skills and knowledge.

- Collaboration with colleagues: Exchange knowledge and ideas with colleagues to stay abreast of industry developments.

8. What is your approach to ensuring workplace safety and following established safety protocols?

- Compliance: Adhere strictly to all workplace safety regulations and protocols.

- Hazard identification: Regularly assess the work area for potential hazards and take appropriate precautions.

- Personal protective equipment (PPE): Wear appropriate PPE, such as safety glasses, gloves, and earplugs, as required.

- Safe work practices: Follow established safe work procedures to prevent accidents and injuries.

- Incident reporting: Promptly report any incidents, accidents, or near misses to supervisors.

9. How do you handle working under pressure and meeting tight deadlines in a fast-paced production environment?

- Prioritization: Prioritize tasks based on urgency and importance to ensure timely completion.

- Time management: Effectively manage time to meet deadlines without compromising quality.

- Stress management: Utilize stress management techniques to maintain focus and productivity under pressure.

- Communication: Communicate regularly with supervisors and colleagues to keep everyone informed and address any challenges.

- Flexibility: Adapt quickly to changing priorities and work assignments to meet deadlines.

10. What are your career goals and how does this role align with your aspirations?

- Career Goals: Aspire to advance my career in the manufacturing industry and contribute to the development of innovative and sustainable production processes.

- Role Alignment: This role provides an excellent platform to enhance my skills, gain experience in advanced manufacturing techniques, and contribute to the company’s success.

- Learning and Growth: Eager to learn from experienced professionals and embrace new challenges to expand my knowledge and capabilities.

- Company Mission: The company’s commitment to technological innovation and sustainability aligns with my values and career aspirations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Manufacturing Production Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Manufacturing Production Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Manufacturing Production Technician, your primary responsibilities will encompass the following key areas:

1. Production Processes

Operate and maintain production equipment, ensuring efficient and accurate manufacturing processes.

- Set up, calibrate, and adjust machines

- Monitor production lines and identify potential issues

2. Quality Control

Conduct quality control inspections and monitor product quality throughout the manufacturing process.

- Inspect raw materials and finished products

- Identify and resolve quality defects

3. Maintenance and Repair

Perform routine maintenance and repairs on production equipment to prevent breakdowns and ensure optimal performance.

- Identify and diagnose equipment issues

- Perform minor repairs and adjustments

4. Safety and Compliance

Adhere to safety regulations and protocols to maintain a safe and compliant work environment.

- Wear appropriate safety gear

- Follow established procedures

Interview Tips

To ace your interview for a Manufacturing Production Technician position, consider these preparation tips:

1. Research the Company and Position

Thoroughly research the company and the specific role you’re applying for. Understand their industry, products, and culture.

- Visit the company website and LinkedIn page

- Read industry articles and news to demonstrate your knowledge

2. Highlight Your Technical Skills

Emphasize your technical skills in operating and maintaining production equipment. Quantify your experience and provide specific examples.

- Discuss your experience with different types of machinery

- Mention your ability to diagnose and resolve equipment issues

3. Showcase Quality Control Expertise

Demonstrate your understanding of quality control principles and your ability to identify and address quality defects.

- Explain your experience in conducting inspections

- Highlight your knowledge of quality management systems

4. Prepare for Safety Questions

Given the importance of safety in manufacturing, be prepared to discuss your understanding of safety regulations and your commitment to following them.

- Mention any safety training or certifications you have

- Explain how you prioritize safety in the workplace

5. Practice Your Answers

Rehearse your answers to common interview questions to ensure you’re articulate and concise. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Prepare for questions about your technical skills, quality control experience, and safety knowledge

- Practice answering questions that highlight your work ethic and problem-solving abilities

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Manufacturing Production Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Manufacturing Production Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.