Feeling lost in a sea of interview questions? Landed that dream interview for Manufacturing Technology Analyst but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Manufacturing Technology Analyst interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

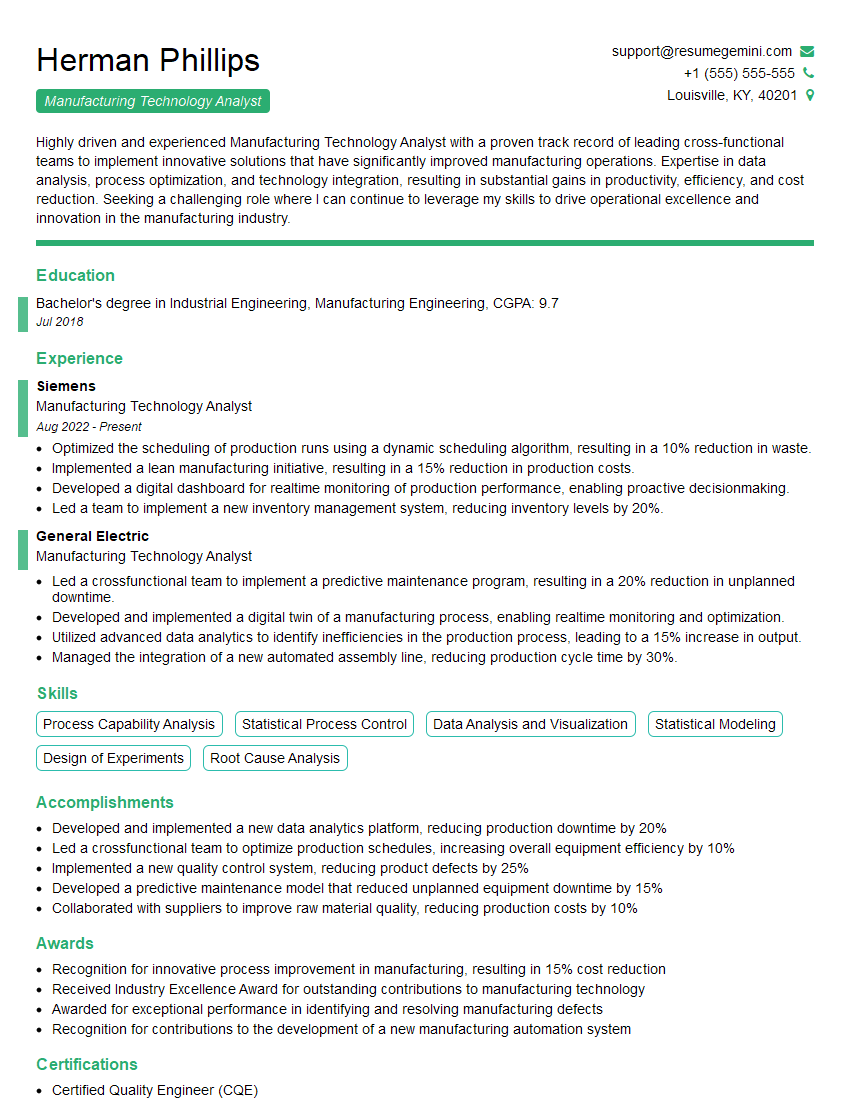

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Manufacturing Technology Analyst

1. Explain the role of manufacturing technology in optimizing production processes?

- Manufacturing technology plays a crucial role in optimizing production processes by automating and streamlining various aspects of manufacturing.

- It enables real-time monitoring and control of production lines, allowing for quick adjustments and preventive maintenance to minimize downtime.

- Advanced technologies like IoT, AI, and robotics enhance efficiency by automating repetitive tasks, improving quality control, and optimizing resource utilization.

- By integrating data analytics and predictive modeling, manufacturers can identify bottlenecks, forecast demand, and optimize production schedules to maximize capacity.

- Overall, manufacturing technology drives productivity gains, reduces costs, and improves the overall competitiveness of manufacturing operations.

2. Describe the key factors to consider when evaluating and selecting manufacturing equipment?

Factors related to the equipment itself:

- Performance specifications (e.g., speed, accuracy, capacity)

- Reliability and durability

- Maintenance requirements and costs

- Energy efficiency and environmental impact

- Compatibility with existing systems and infrastructure

Factors related to the manufacturing process:

- Production volume and mix

- Material properties and characteristics

- Quality standards and tolerances

- Workflow and layout of the production line

- Availability of skilled labor and training requirements

Factors related to cost and return on investment:

- Initial purchase price and ongoing operating costs

- Projected productivity improvements and cost savings

- Return on investment timeline and expected payback period

3. How do you stay up-to-date with the latest advancements in manufacturing technology?

- Attend industry conferences, trade shows, and webinars to learn about new technologies and trends.

- Read industry publications, whitepapers, and research papers to stay informed about advancements.

- Network with peers and experts in the field to exchange knowledge and experiences.

- Utilize online resources, such as manufacturer websites and technology blogs, to access the latest information.

- Enroll in online courses and certification programs to gain specialized knowledge and skills.

4. How do you apply your knowledge of manufacturing processes to improve efficiency and reduce costs?

- Analyze production processes to identify bottlenecks and inefficiencies.

- Recommend and implement technology upgrades or process improvements to streamline operations.

- Optimize equipment utilization and maintenance schedules to minimize downtime.

- Develop and implement quality control measures to reduce defects and waste.

- Collaborate with production teams to identify areas for improvement and implement solutions.

5. What are some of the challenges you face as a Manufacturing Technology Analyst?

- Keeping up with the rapid pace of technological advancements.

- Balancing the need for innovation with the constraints of legacy systems and processes.

- Overcoming resistance to change from stakeholders and employees.

- Justifying the investment in new technologies and demonstrating their value.

- Integrating new technologies with existing infrastructure and ensuring compatibility.

6. How do you prioritize and manage multiple projects?

- Identify and define the scope and objectives of each project.

- Establish clear priorities based on business impact, timelines, and resource availability.

- Create a project plan that outlines tasks, dependencies, and milestones.

- Communicate project plans and timelines to stakeholders and team members.

- Monitor project progress regularly and make adjustments as needed.

7. How do you measure the success of manufacturing technology initiatives?

- Establish key performance indicators (KPIs) that align with business objectives, such as productivity, quality, cost, and efficiency.

- Collect and analyze data to track progress towards these KPIs.

- Compare results to pre-implementation benchmarks or industry standards.

- Conduct regular reviews to assess the impact of technology initiatives and identify areas for improvement.

- Seek feedback from stakeholders and users to gather qualitative insights.

8. What are your thoughts on the role of automation in manufacturing?

- Automation has the potential to significantly improve manufacturing efficiency and productivity.

- It can free up human workers from repetitive and hazardous tasks, allowing them to focus on higher-value activities.

- However, it is important to consider the impact of automation on employment and the need for reskilling and upskilling initiatives.

- The responsible implementation of automation can lead to improved working conditions, increased competitiveness, and economic growth.

9. How do you approach problem-solving in manufacturing technology?

- Define the problem clearly and gather relevant data.

- Explore potential causes and identify root issues.

- Develop and evaluate multiple solutions based on technical feasibility and business impact.

- Implement the selected solution and monitor its effectiveness.

- Document the problem-solving process and lessons learned for future reference.

10. What is your understanding of Industry 4.0 and its implications for manufacturing?

- Industry 4.0 refers to the fourth industrial revolution, characterized by the integration of advanced technologies such as IoT, AI, and automation.

- It has the potential to transform manufacturing by enabling real-time data collection, predictive analytics, and autonomous decision-making.

- Industry 4.0 can lead to increased productivity, improved quality, and personalized production.

- However, it also presents challenges such as cybersecurity risks and the need for skilled workers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Manufacturing Technology Analyst.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Manufacturing Technology Analyst‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Manufacturing Technology Analysts are responsible for investigating, recommending, and implementing new manufacturing technologies to improve efficiency and productivity. They work closely with engineers, production managers, and other stakeholders to identify areas for improvement and develop solutions.

1. Research and Analysis

Manufacturing Technology Analysts research and analyze manufacturing processes and technologies to identify areas for improvement. They use their knowledge of manufacturing principles and best practices to develop recommendations for new technologies and processes that can improve efficiency, quality, and productivity.

- Identify and evaluate new manufacturing technologies.

- Analyze manufacturing processes to identify inefficiencies and bottlenecks.

- Develop recommendations for new technologies and processes to improve efficiency and productivity.

2. Project Implementation

Manufacturing Technology Analysts work with engineers and production managers to implement new technologies and processes. They provide technical support and guidance to ensure that the new technologies are implemented correctly and effectively.

- Work with engineers to develop and implement new manufacturing technologies.

- Provide technical support to production managers during the implementation of new technologies.

- Monitor the performance of new technologies and make adjustments as needed.

3. Data Analysis and Reporting

Manufacturing Technology Analysts collect and analyze data on manufacturing processes and technologies. They use this data to identify trends and patterns, and to develop recommendations for improvements. They also prepare reports on the performance of new technologies and processes.

- Collect and analyze data on manufacturing processes and technologies.

- Identify trends and patterns in the data.

- Prepare reports on the performance of new technologies and processes.

4. Training and Development

Manufacturing Technology Analysts provide training and development to engineers, production managers, and other stakeholders on new manufacturing technologies and processes. They also develop training materials and programs to ensure that employees are up-to-date on the latest technologies.

- Provide training and development to engineers, production managers, and other stakeholders on new manufacturing technologies and processes.

- Develop training materials and programs to ensure that employees are up-to-date on the latest technologies.

- Conduct workshops and seminars on new manufacturing technologies and processes.

Interview Tips

Preparing for an interview for a Manufacturing Technology Analyst position can be a daunting task. However, by following a few simple tips, you can increase your chances of success.

1. Research the Company and the Position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the position. You can find information about the company on their website, social media pages, and Glassdoor.

- Make a list of questions to ask the interviewer about the company and the position.

- Practice answering common interview questions.

2. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the position. This includes your technical skills, as well as your experience in manufacturing and technology. You can also highlight your soft skills, such as your communication and teamwork skills.

- Prepare a resume and cover letter that highlight your skills and experience.

- Bring examples of your work to your interview.

3. Be Prepared to Answer Technical Questions

In addition to general interview questions, you can also expect to be asked technical questions about manufacturing and technology. Be prepared to answer questions about your knowledge of manufacturing processes, technologies, and software. You can also expect to be asked about your experience with data analysis and project management.

- Review your knowledge of manufacturing processes and technologies.

- Practice answering technical questions with specific examples.

4. Be Enthusiastic and Professional

Finally, be sure to be enthusiastic and professional during your interview. This will show the interviewer that you are interested in the position and that you are a good fit for the company. Be respectful of the interviewer’s time and answer their questions honestly and concisely.

- Dress professionally for your interview.

- Be on time for your interview.

- Thank the interviewer for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Manufacturing Technology Analyst interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!