Are you gearing up for a career in Marshmallow Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Marshmallow Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

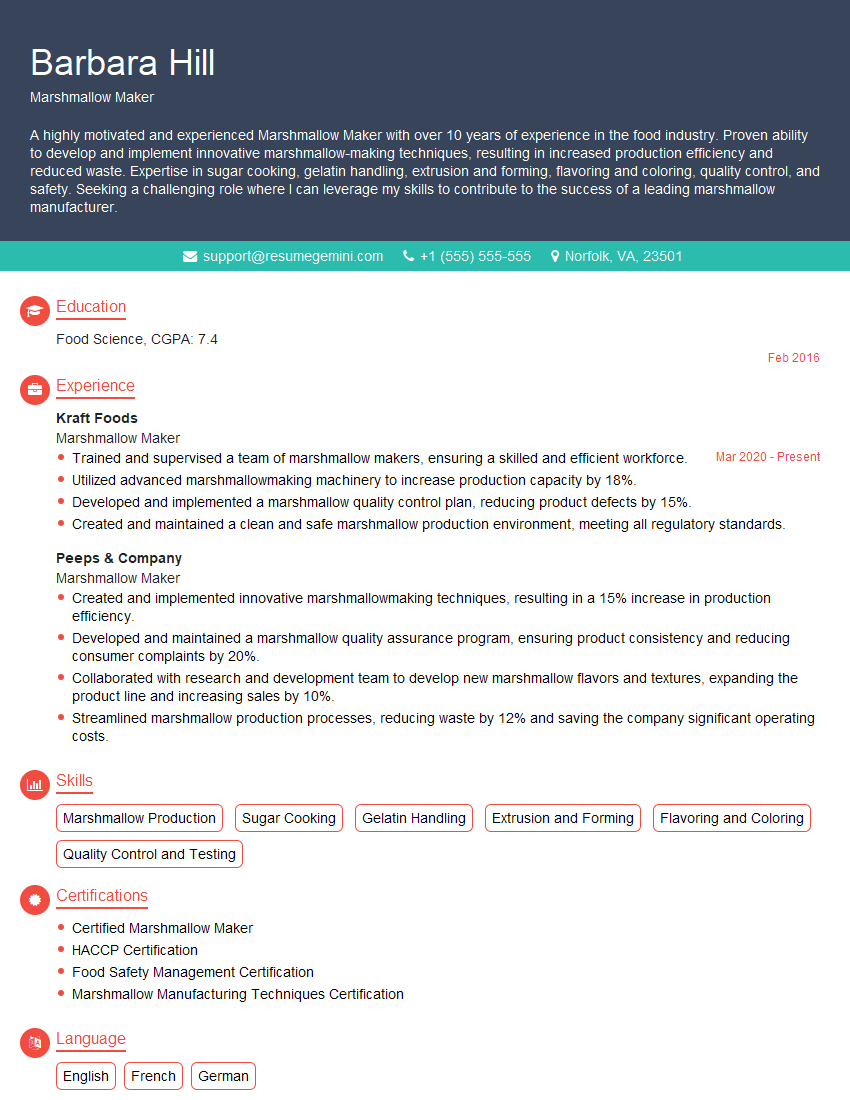

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Marshmallow Maker

1. Describe the process of making marshmallows. Mention the key ingredients and any specialized equipment you have used in the past.

Key Ingredients:

- Sugar

- Water

- Corn syrup

- Gelatin

- Flavoring (optional)

Process:

- Combine sugar, water, and corn syrup in a large pot and bring to a boil.

- Add gelatin and stir until dissolved.

- Remove from heat and add flavoring (if desired).

- Pour mixture into a lightly greased pan and let cool.

- Cut into desired shapes.

Specialized Equipment:

- Candy thermometer

- Stand mixer

- Marshmallow cutter

2. What are the different types of marshmallows and how are they made?

Traditional Marshmallows

These are the most common type of marshmallow and are made with the basic ingredients listed above. They can be flavored or unflavored, and can be cut into various shapes.

Specialty Marshmallows

These marshmallows are made with additional ingredients to create unique flavors or textures. Some popular specialty marshmallows include:

- Fruit-flavored marshmallows

- Chocolate marshmallows

- Caramel marshmallows

- Marshmallows with fillings

Gourmet Marshmallows

These marshmallows are made with high-quality ingredients and are often handcrafted. They may be flavored with unique ingredients or have special textures. Gourmet marshmallows are often used in desserts and other culinary applications.

3. What are the common defects that can occur during marshmallow production and how can they be prevented?

Common Defects:

- Grainy texture: Caused by insufficient mixing or crystallization.

- Chewy texture: Caused by undercooking.

- Hard texture: Caused by overcooking.

- Discolored marshmallows: Caused by caramelization or oxidation.

- Malformed marshmallows: Caused by improper cutting or handling.

Prevention:

- Grainy texture: Ensure thorough mixing and prevent crystallization by using a candy thermometer.

- Chewy texture: Cook the marshmallow mixture to the correct temperature.

- Hard texture: Do not overcook the marshmallow mixture.

- Discolored marshmallows: Prevent caramelization by cooking the mixture at the correct temperature and packaging marshmallows in airtight containers.

- Malformed marshmallows: Use a sharp marshmallow cutter and handle marshmallows carefully.

4. How do you maintain the quality of marshmallows over time?

To maintain the quality of marshmallows over time, it is important to:

- Store marshmallows in an airtight container: This will prevent them from drying out or absorbing moisture.

- Keep marshmallows in a cool, dry place: Heat and humidity can cause marshmallows to deteriorate.

- Avoid freezing marshmallows: Freezing can damage the texture and flavor of marshmallows.

- Use marshmallows within 6 months of production: This will ensure that they are at their best quality.

5. What are the latest trends in marshmallow production?

Some of the latest trends in marshmallow production include:

- Use of natural ingredients: Consumers are increasingly demanding marshmallows made with natural ingredients, such as fruit purees and extracts.

- Production of specialty marshmallows: Marshmallow makers are creating new and innovative flavors and textures, such as marshmallows with fillings, coatings, and unique shapes.

- Development of new packaging: Marshmallow makers are developing new packaging solutions to extend the shelf life and maintain the quality of marshmallows.

6. How do you ensure the safety of marshmallow products?

To ensure the safety of marshmallow products, it is important to:

- Follow Good Manufacturing Practices (GMPs): GMPs are a set of regulations that ensure the safety and quality of food products.

- Use high-quality ingredients: All ingredients used in marshmallow production should be of the highest quality and meet all safety standards.

- Maintain a clean and sanitary production environment: The production area should be kept clean and sanitized to prevent contamination.

- Test marshmallow products regularly: Marshmallow products should be tested regularly to ensure that they meet all safety and quality standards.

7. What is your experience in troubleshooting marshmallow production issues?

I have experience in troubleshooting a variety of marshmallow production issues, including:

- Grainy texture: I have resolved this issue by ensuring thorough mixing and preventing crystallization by using a candy thermometer.

- Chewy texture: I have resolved this issue by cooking the marshmallow mixture to the correct temperature.

- Hard texture: I have resolved this issue by not overcooking the marshmallow mixture.

- Discolored marshmallows: I have resolved this issue by preventing caramelization by cooking the mixture at the correct temperature and packaging marshmallows in airtight containers.

- Malformed marshmallows: I have resolved this issue by using a sharp marshmallow cutter and handling marshmallows carefully.

8. How do you stay up-to-date on the latest developments in marshmallow production?

I stay up-to-date on the latest developments in marshmallow production by:

- Reading industry publications: I read trade magazines and journals to learn about new trends and technologies.

- Attending industry events: I attend conferences and workshops to learn from experts and network with other marshmallow makers.

- Experimenting with new ingredients and techniques: I am always experimenting with new ingredients and techniques to improve the quality and flavor of my marshmallows.

9. What are your strengths as a marshmallow maker?

My strengths as a marshmallow maker include:

- Attention to detail: I am very detail-oriented and take pride in producing high-quality marshmallows.

- Problem-solving skills: I am able to quickly identify and resolve marshmallow production issues.

- Creativity: I am always experimenting with new ingredients and techniques to create unique and innovative marshmallows.

- Teamwork: I am a team player and am able to work effectively with others to produce high-quality marshmallows.

10. What are your goals for the future as a marshmallow maker?

My goals for the future as a marshmallow maker are to:

- Continue to produce high-quality marshmallows: I am committed to producing marshmallows that meet the highest standards of quality and safety.

- Innovate and create new marshmallows: I am always looking for new and innovative ways to create unique and delicious marshmallows.

- Expand my business: I am interested in expanding my marshmallow business to reach a wider market.

- Train and mentor other marshmallow makers: I am passionate about sharing my knowledge and experience with others and would like to train and mentor other marshmallow makers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Marshmallow Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Marshmallow Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Marshmallow Maker is responsible for ensuring a reliable supply of fresh marshmallows for production and packaging. The job entails supervising the production process, maintaining equipment, and performing routine quality checks. Key responsibilities for this role include:

1. Production Supervision

Supervising the marshmallow production process to ensure it meets quality and quantity requirements. Monitoring the filling, forming, cutting, and drying stages to minimize defects and downtime.

- Coordinating with production team to ensure smooth workflow and adherence to production schedules.

- Identifying and troubleshooting production issues to maintain optimal efficiency and yield.

2. Equipment Maintenance

Maintaining and cleaning marshmallow making equipment to ensure its proper functioning. Conducting regular inspections, calibrations, and repairs as needed. Ensuring compliance with safety regulations and hygiene standards.

- Monitoring equipment performance to predict and prevent breakdowns, minimizing downtime.

- Maintaining a clean and organized work area, adhering to GMP (Good Manufacturing Practices) guidelines.

3. Quality Control

Performing routine quality checks on marshmallows throughout the production process. Inspecting marshmallows for size, shape, texture, and flavor. Ensuring compliance with specifications and customer requirements.

- Maintaining detailed records of quality control checks and implementing corrective actions as needed.

- Analyzing quality trends to identify areas for improvement and optimize production processes.

4. Inventory Management

Monitoring marshmallow inventory levels and coordinating with the supply chain to ensure a constant supply of raw materials and packaging. Minimizing waste and optimizing inventory to meet production targets.

- Collaborating with suppliers to secure timely deliveries and maintain quality standards.

- Implementing inventory management systems to track stock levels, minimize spoilage, and reduce costs.

Interview Tips

To ace your interview for a Marshmallow Maker position, consider the following tips:

1. Research the Company and Role

Learn about the company’s marshmallow production processes, products, and market position. Familiarize yourself with the specific responsibilities and requirements of the Marshmallow Maker role.

- Visit the company’s website and social media platforms to gather information about their operations and culture.

- Review industry publications and news articles to stay updated on trends and advancements in marshmallow manufacturing.

2. Highlight Relevant Experience and Skills

In your resume and interview, emphasize your experience in marshmallow production, equipment maintenance, or quality control. Quantify your accomplishments and provide specific examples of how you contributed to improving production efficiency, quality, or cost reduction.

- If you have experience in a similar role, highlight your understanding of marshmallow production processes and your ability to supervise and troubleshoot.

- Demonstrate your mechanical aptitude and problem-solving skills by sharing instances where you successfully maintained or repaired marshmallow making equipment.

3. Emphasize Attention to Detail and Quality

Marshmallow production requires meticulous attention to detail and a commitment to quality. During the interview, emphasize your ability to inspect marshmallows for defects, maintain accurate records, and implement corrective actions when necessary.

- Provide examples of how you have maintained high standards of hygiene and sanitation in previous roles.

- Explain your understanding of quality control principles and your experience in using statistical process control or other quality management tools.

4. Prepare for Technical Questions

Be prepared to answer technical questions about marshmallow production processes, equipment, and quality control. Review basic principles of sugar crystallization, foaming agents, and drying techniques. Practice troubleshooting common issues that may arise during marshmallow production.

- Research different types of marshmallow making equipment and their functions.

- Familiarize yourself with common quality defects in marshmallows, such as stickiness, clumping, or shrinkage.

5. Show Enthusiasm and Passion

Let the interviewer know that you are genuinely interested in the Marshmallow Maker role and that you have a passion for creating high-quality marshmallows. Express your eagerness to learn and contribute to the company’s success.

- Share your knowledge of different marshmallow flavors and trends, demonstrating your interest in the industry.

- Explain why you are motivated to work in a production environment and enjoy the challenges of ensuring product quality.

Next Step:

Now that you’re armed with the knowledge of Marshmallow Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Marshmallow Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini