Feeling lost in a sea of interview questions? Landed that dream interview for Mash Preparatory Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mash Preparatory Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

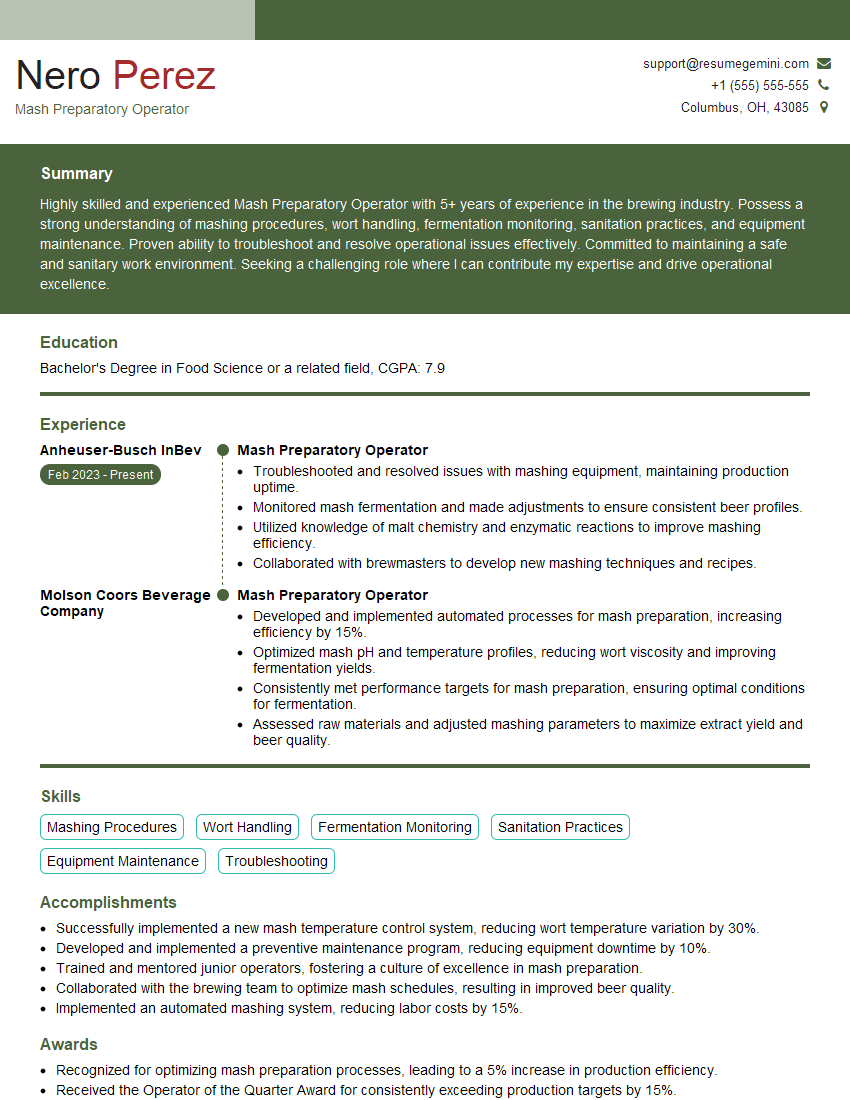

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mash Preparatory Operator

1. Explain the process of preparing mash for fermentation.

The process of preparing mash for fermentation involves several steps:

- Milling: The grains are coarsely ground to expose the starch.

- Mashing-in: The ground grains are mixed with hot water in a mash tun to create a mash. The temperature is carefully controlled to activate enzymes that convert the starch into sugars.

- Saccharification: The mash is held at specific temperatures to allow the enzymes to break down the starch into fermentable sugars. This process typically lasts for several hours.

- Lautering: The mash is transferred to a lauter tun, where the liquid (wort) is separated from the solids (spent grains). The wort is collected and used for fermentation.

- Sparging: Hot water is sprayed over the spent grains to extract any remaining sugars.

- Boiling: The wort is boiled to sterilize it and isomerize the hop compounds, adding bitterness and aroma to the beer.

2. What are the different types of mashing methods?

- Single-temperature mashing: The mash is held at a single temperature throughout the saccharification process.

- Step-mashing: The mash is heated to different temperatures in stages to facilitate the work of different enzymes.

- Infusion mashing: Hot water is added to the mash all at once, and the temperature is controlled by the heat capacity of the water.

- Decoction mashing: A portion of the mash is removed, boiled, and then returned to the main mash to raise the temperature.

3. How do you calculate the amount of water and grain needed for a specific batch size?

To calculate the amount of water and grain needed, you need to consider the following factors:

- Batch size: The desired volume of finished beer.

- Grain bill: The types and proportions of grains used.

- Grain absorption: The amount of water absorbed by the grains.

- Mash thickness: The ratio of grain to water in the mash.

The calculations involve using formulas and adjusting the parameters based on experience and desired results.

4. What equipment is essential for a mash preparation area?

- Mill: For grinding the grains.

- Mash tun: For mixing and holding the mash.

- Lauter tun: For separating the wort from the spent grains.

- Heating elements: For controlling mash temperature.

- Pumps: For transferring the mash and wort.

- Thermometers: For monitoring temperatures.

- Refractometer: For measuring the specific gravity of the wort.

5. How do you maintain proper sanitation in the mash preparation area?

Maintaining proper sanitation is crucial to prevent contamination. Key practices include:

- Cleaning and disinfecting: Regularly cleaning and disinfecting all equipment and surfaces.

- Personal hygiene: Wearing appropriate protective gear and practicing good hygiene.

- Monitoring pH levels: Ensuring the pH of the mash is within the optimal range for enzyme activity.

- Wort boiling: Boiling the wort to sterilize it.

6. What are the common problems that can occur during mash preparation?

- Stuck mash: The mash becomes too thick and cannot be lautered properly. This can be caused by insufficient enzymes, incorrect mash thickness, or poor water quality.

- Wort infection: Contamination by bacteria or wild yeast can spoil the wort, causing off-flavors or spoilage.

- Insufficient enzyme activity: Enzymes may not be active enough to convert all of the starch into sugars, leading to low beer yield.

- Inadequate lautering: The wort is not properly separated from the spent grains, resulting in a cloudy beer.

7. What types of adjustments can be made to the mashing process to achieve different beer styles?

Adjustments to the mashing process can influence the characteristics of the finished beer:

- Grain bill: Different grains have different sugar profiles, affecting the sweetness and body of the beer.

- Mash temperature: Higher mash temperatures produce more fermentable sugars, resulting in a drier beer, while lower temperatures produce a sweeter beer.

- Mash duration: Longer mashing times allow for more complete sugar conversion, leading to a higher alcohol content.

- Mash pH: The pH of the mash affects enzyme activity and can influence the flavor and clarity of the beer.

8. How do you optimize mash preparation for specific beer styles?

To optimize mash preparation for specific beer styles, you need to consider the following factors:

- Desired flavor profile: Different beer styles have unique flavor characteristics that can be achieved through specific mashing techniques.

- Target alcohol content: The mashing process can be adjusted to produce beers with varying alcohol levels.

- Body and mouthfeel: The choice of grains and mashing parameters can influence the body and mouthfeel of the beer.

- Clarity: Some beer styles require a clear wort, while others can tolerate some haze.

9. What safety precautions should be taken during mash preparation?

- Wear appropriate protective gear: Gloves, safety glasses, and appropriate footwear.

- Handle hot liquids with care: Mash and wort can be very hot, so take precautions to avoid burns.

- Maintain a clean and organized work area: Spills and clutter can lead to accidents.

- Be aware of moving equipment: Pumps and other machinery can pose hazards, so pay attention to your surroundings.

- Follow established procedures: Adhere to standard operating procedures to minimize risks.

10. What is the role of pH in mash preparation?

- Enzyme activity: The pH of the mash directly affects the activity of enzymes involved in starch conversion.

- Mash conversion efficiency: Optimal pH levels ensure efficient conversion of starch into fermentable sugars.

- Flavor and stability: pH can influence the flavor profile and stability of the beer.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mash Preparatory Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mash Preparatory Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

To be successful in this role, you will need to have a strong understanding of the different types of mash and the brewing process. You will also need to be able to work independently and as part of a team, and have a good attention to detail.

1. Prepare and operate mash tuns

This involves adding milled grain to water, mixing it thoroughly, and maintaining the correct temperature and pH levels for the mash.

- Weigh and measure ingredients according to recipes

- Operate and maintain mash tuns, lauter tuns, and other equipment

- Monitor and adjust temperature, pH, and other process parameters

- Clean and sanitize equipment

2. Monitor and adjust the mashing process

This involves checking the temperature, pH, and other parameters of the mash, and making adjustments as needed to ensure that the mash is progressing correctly.

- Take samples of the mash and analyze them

- Make adjustments to the mash as needed

- Maintain records of the mashing process

- Troubleshoot problems with the mashing process

3. Transfer the mash to the lauter tun

Once the mashing process is complete, the mash is transferred to the lauter tun, where the wort is separated from the spent grain.

- Operate and maintain lauter tuns

- Transfer mash to lauter tuns

- Monitor and adjust lauter tun operation

- Clean and sanitize lauter tuns

4. Clean and maintain equipment

It is important to keep all equipment clean and sanitized to prevent contamination. This involves following proper cleaning and sanitization procedures, and inspecting equipment regularly for any damage or wear.

- Clean and sanitize all equipment that comes into contact with the mash or wort

- Inspect equipment regularly for damage or wear

- Follow proper cleaning and sanitization procedures

- Maintain a clean and organized work area

Interview Tips

Here are some tips to help you ace your interview for a Mash Preparatory Operator position:

1. Research the company and the position

This will help you understand the company’s culture and values, as well as the specific requirements of the position. The more you know about the company and the position, the better prepared you will be to answer questions and demonstrate your qualifications.

2. Practice your answers to common interview questions

Some common interview questions that you may be asked include: “Tell me about yourself,” “Why are you interested in this position?,” and “What are your strengths and weaknesses?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

Sample answers to these common interview questions:Tell me about yourself.

– A well-crafted answer to this question should include a brief overview of your professional background, your skills and experience, and your career goals. For example: “I am a highly motivated and results-oriented Mash Preparatory Operator with 5 years of experience in the brewing industry. I have a strong understanding of the mashing process and have a proven track record of producing high-quality wort. I am also proficient in operating and maintaining mash tuns and lauter tuns.”

Why are you interested in this position?

– In your answer, you should express your interest in the company and the position. You should also highlight your skills and experience that make you a good fit for the role. For example: “I am interested in this position because I am passionate about the brewing industry and I am eager to learn more about the mashing process. I am confident that my skills and experience would be a valuable asset to your team.”

What are your strengths and weaknesses?

– When answering this question, it is important to be honest and self-aware. You should focus on your strengths and how they would benefit the company. You should also acknowledge your weaknesses and explain how you are working to improve them. For example: “One of my strengths is my attention to detail. I am always careful to follow instructions and procedures, and I am always checking my work to make sure it is accurate. One of my weaknesses is that I am sometimes too detail-oriented, and I can get bogged down in the details. However, I am working on improving this by taking a step back and looking at the big picture more often.”

3. Be prepared to talk about your experience

The interviewer will want to know about your experience in the brewing industry, so be prepared to talk about your previous roles and responsibilities. Be sure to highlight your accomplishments and any skills or knowledge that would be relevant to the position you are applying for.

4. Dress professionally and be on time for your interview

First impressions matter, so it is important to dress professionally and be on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the position.

5. Be confident and enthusiastic

Confidence and enthusiasm can go a long way in an interview. Be confident in your abilities and be enthusiastic about the opportunity to work for the company. This will show the interviewer that you are excited about the position and that you are eager to contribute to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mash Preparatory Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.