Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mash Tub Cooker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mash Tub Cooker so you can tailor your answers to impress potential employers.

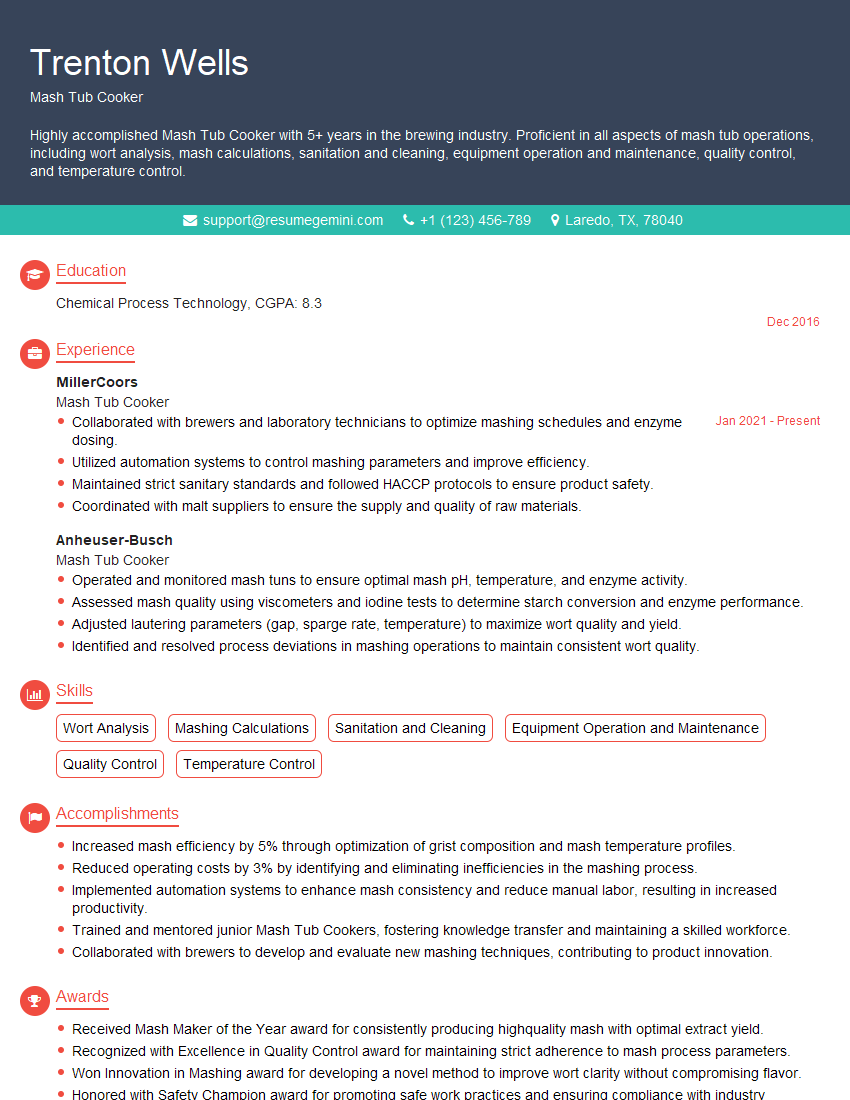

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mash Tub Cooker

1. Explain the fundamental principles of mashing?

Mashing is a crucial step in beer production that involves converting the starches in malted barley into fermentable sugars. The fundamental principles of mashing include:

- Enzymatic conversion: Enzymes present in the malt, primarily alpha-amylase and beta-amylase, break down the complex starches into simpler sugars, such as glucose and maltose.

- Temperature control: Different enzymes work optimally at specific temperatures. Mashing is typically carried out in stages at different temperatures to target specific enzymes and achieve the desired sugar profile.

- pH control: The pH of the mash affects enzyme activity. Maintaining an optimal pH, typically between 5.2 and 5.6, ensures efficient enzyme activity.

- Mash consistency: The ratio of water to grist (crushed malt) affects the efficiency of enzymatic conversion. A suitable mash consistency allows for adequate enzyme-starch interaction.

2. Describe the role of sparge water in the mashing process?

Sparging

- Sparging involves slowly rinsing the mash with hot water to extract the remaining sugars and other soluble compounds.

- It helps increase the wort volume and extract efficiency.

Water quality

- Sparge water should be of good quality, with low mineral content and appropriate pH.

- High levels of certain minerals, such as calcium or magnesium, can interfere with enzymatic activity and alter the wort composition.

Sparging temperature

- Sparge water temperature should be around 75-78°C (167-172°F) to avoid denaturing enzymes and promoting bacterial growth.

- Higher temperatures can lead to caramelization and alter the wort’s flavor profile.

3. What are the common types of lauter tuns and their advantages and disadvantages?

There are two main types of lauter tuns:

- Gravity lauter tuns:

- Advantages: Simple design, no moving parts, lower cost.

- Disadvantages: Slower lautering process, potential for channeling and uneven wort extraction.

- Screen lauter tuns:

- Advantages: Faster lautering, improved wort clarity, reduced channeling.

- Disadvantages: More complex design, moving parts (screen), higher maintenance.

4. How can you troubleshoot and resolve problems during lautering?

Common lautering problems and troubleshooting steps include:

- Slow lautering: Check for proper mash consistency, clogged lauter plate, or channeling. Adjust mash thickness, clean the plate, or use lautering aids.

- Stuck lauter: Stop sparging and allow the lauter bed to settle. Gently stir the bed or use a lautering rake to break up clumps.

- Channeling: Identify the source of channeling by gradually increasing the sparge flow rate. Use lautering aids to prevent channeling and improve wort uniformity.

5. Explain the role of boiling in the wort production process?

Boiling serves multiple important roles in wort production:

- Sterilization: Boiling kills microorganisms present in the wort, ensuring its microbiological stability.

- Evaporation: Boiling evaporates water, concentrating the wort and increasing its sugar content.

- Isoalpha acid extraction: Boiling helps extract isohumulones from hop cones, imparting bitterness to the beer.

- Protein coagulation: Boiling denatures proteins, causing them to coagulate and form hot break, which is later removed.

6. What are the different types of hop additions and their effects on beer flavor?

Hop additions are made at various stages of the brewing process to impart different flavors and aromas:

- Early additions (bittering): Hops added early in the boil contribute primarily to bitterness. The longer they are boiled, the more bitter the beer becomes.

- Late additions (flavor/aroma): Hops added towards the end of the boil or during whirlpool contribute to flavor and aroma rather than bitterness.

- Dry hopping (post-fermentation): Hops added after fermentation impart fresh, hoppy aromas and flavors.

- Double dry hopping: A second addition of hops during conditioning further enhances hop character.

7. How do you control the fermentation temperature and why is it important?

Fermentation temperature plays a crucial role in beer quality:

- Yeast strain selection: Different yeast strains have optimal fermentation temperature ranges.

- Flavor development: Fermentation temperature influences the production of esters, phenols, and other flavor compounds.

- Fermentation rate: Higher temperatures accelerate fermentation, while lower temperatures slow it down.

- Temperature control: Fermentation vessels are typically cooled using glycol chillers or fermentation jackets to maintain the desired temperature range.

8. Describe the role of conditioning and maturation in the beer production process?

- Conditioning:

- After primary fermentation, beer is cooled and allowed to settle. This allows yeast to flocculate and sediment out.

- Conditioning helps clarify the beer and remove undesirable flavors.

- Maturation:

- Beer is stored at cooler temperatures for an extended period, allowing for further flavor development and aging.

- Maturation improves the beer’s stability, smoothness, and complexity.

9. What quality control measures are implemented to ensure the production of high-quality beer?

Quality control measures include:

- Raw material inspection: Checking the quality of malt, hops, and other ingredients.

- Process monitoring: Tracking critical parameters such as temperature, pH, and gravity throughout the brewing process.

- Sensory evaluation: Assessing the beer’s appearance, aroma, flavor, and mouthfeel to ensure it meets quality standards.

- Microbiological testing: Monitoring for spoilage microorganisms to ensure the beer’s safety and stability.

- Packaging inspection: Checking containers and seals to prevent contamination and ensure product integrity.

10. Stay updated with the latest brewing techniques and advancements?

- Attend industry conferences and workshops.

- Read industry publications and research papers.

- Network with other brewers and industry professionals.

- Experiment with new ingredients and brewing methods responsibly.

- Stay informed about technological advancements in brewing equipment and processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mash Tub Cooker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mash Tub Cooker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Mash Tub Cooker is responsible for the efficient operation of the mash tub, a crucial vessel used in the brewing process to convert starch into fermentable sugars. Their primary duties include:1. Mashing Process Management

– Accurately measuring and adding grist (crushed malt) and water to create the mash, adhering to pre-determined recipes. – Monitoring mash temperature throughout the process, maintaining optimal conditions for enzyme activity and sugar conversion. – Controlling the mash’s pH level to optimize enzyme performance and extract desired flavors.2. Wort Separation

– Operating the lauter tun to separate the liquid wort (containing sugars) from the spent grain (husks and protein). – Adjusting the flow rate and sparge water quantity to maximize wort extraction and minimize grain loss. – Ensuring proper lauter tun operation to prevent clogging and maintain wort clarity.3. Quality Control and Maintenance

– Monitoring wort quality parameters, such as specific gravity and temperature, to ensure it meets specifications. – Performing routine cleaning and maintenance of the mash tub and related equipment to maintain hygiene and prevent contamination. – Calibrating and maintaining equipment to ensure process accuracy and consistency.4. Collaboration and Communication

– Coordinating with other brewery departments, including the brewhouse and fermentation teams, to ensure smooth production flow. – Maintaining accurate records of mashing and wort separation parameters to facilitate quality control and process optimization. – Communicating any deviations from standard operating procedures to supervisors and managers.Interview Tips

To ace the interview for a Mash Tub Cooker position, candidates should prepare thoroughly and demonstrate their:1. Technical Expertise

– Highlight your knowledge of the mashing process, wort separation, and quality control procedures. – Be prepared to discuss enzyme activity, mash temperature, pH adjustment, and wort quality parameters.2. Operational Proficiency

– Showcase your experience in operating mash tubs, lauter tuns, and related equipment. – Emphasize your ability to maintain optimal conditions and handle troubleshooting situations effectively.3. Communication Skills

– Demonstrate strong communication and interpersonal skills, emphasizing your ability to coordinate with other brewery departments. – Prepare to give examples of how you effectively communicated deviations from standard procedures and collaborated on process improvements.4. Problem-Solving and Analytical Abilities

– Highlight your ability to identify and resolve issues related to mashing, wort separation, and equipment maintenance. – Provide examples of how you used analytical thinking to optimize processes and improve wort quality.By preparing thoroughly and showcasing your technical expertise, operational proficiency, communication skills, and problem-solving abilities, you will significantly increase your chances of impressing the interviewer and securing the Mash Tub Cooker position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Mash Tub Cooker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Mash Tub Cooker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.