Are you gearing up for a career in Masking Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Masking Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

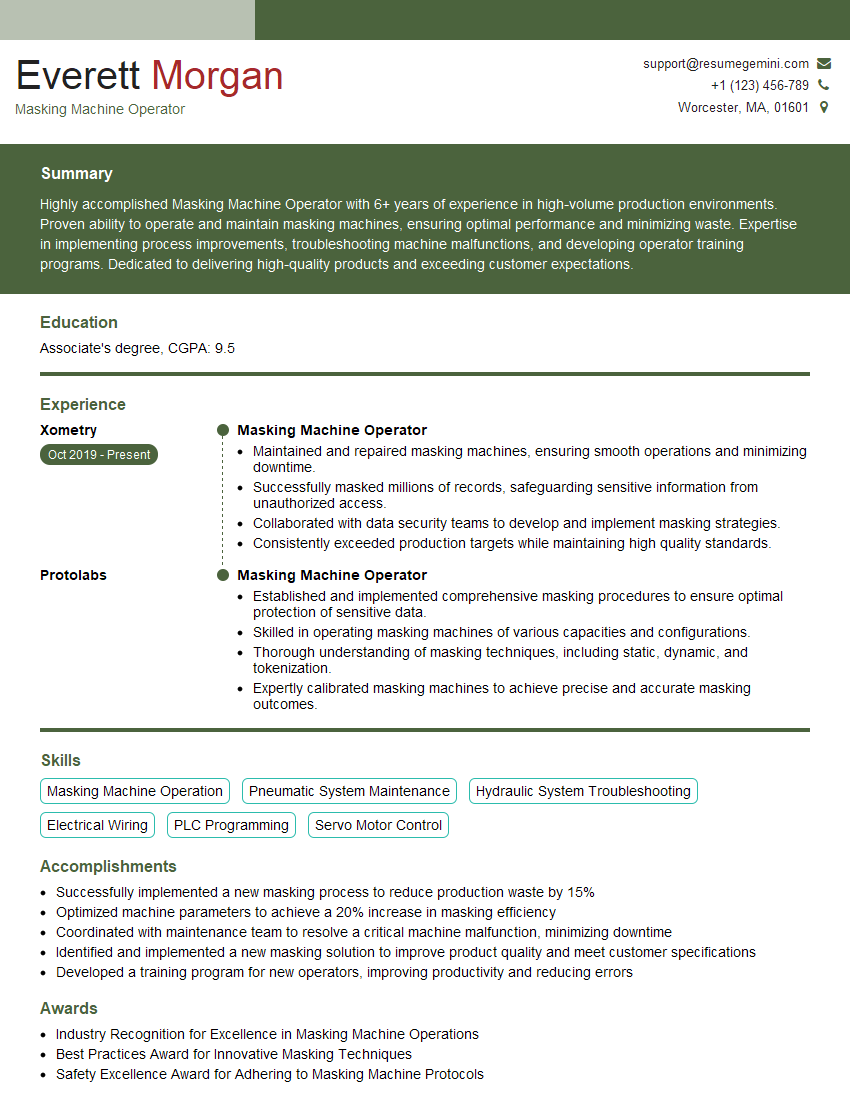

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Masking Machine Operator

1. How would you ensure proper alignment when inserting parts into the masking machine?

To ensure proper alignment, I would take the following steps:

- First, I would use the machine’s alignment tools to ensure that the parts are correctly positioned.

- Next, I would manually adjust the parts as needed to ensure that they are perfectly aligned.

- Finally, I would double-check the alignment by visually inspecting the parts before starting the masking process.

2. Can you describe the different types of masking materials used in the masking process and their applications?

Types of Masking Materials

- Paper Masking Tape: Used for general masking applications, adheres well to most surfaces, and is easy to remove.

- Plastic Masking Tape: Used for masking delicate surfaces or curves, provides higher temperature resistance, and is less likely to leave adhesive residue.

- Vinyl Masking Tape: Used for long-term masking applications, conforms well to irregular surfaces, and is resistant to chemicals and solvents.

Applications

- automotive painting

- metalworking

- electronics

- composite manufacturing

3. How would you troubleshoot a situation where the masking tape is not adhering properly to the parts?

If the masking tape is not adhering properly, I would troubleshoot the situation by:

- Ensuring that the parts are clean and free of any dirt or oils.

- Checking the temperature of the parts. The masking tape may not adhere properly if the parts are too hot or too cold.

- Adjusting the pressure of the masking machine. Too much or too little pressure can cause the masking tape to not adhere properly.

- Trying a different type of masking tape. Some types of tape may adhere better to certain surfaces than others.

4. How do you maintain and clean masking machine parts?

I would maintain and clean the masking machine parts by:

- Regularly cleaning the machine’s rollers and guides with a soft cloth.

- Lubricating the machine’s moving parts with a light oil.

- Inspecting the machine’s belts and replacing them if they are worn or damaged.

- Storing the machine in a clean and dry environment.

5. How would you prioritize multiple masking jobs with different deadlines?

I would prioritize multiple masking jobs with different deadlines by:

- First, I would determine the urgency of each job. Some jobs may be more time-sensitive than others.

- Next, I would consider the availability of resources. I may need to adjust the schedule if I do not have enough staff or equipment to complete all of the jobs on time.

- Finally, I would communicate the revised schedule to the customers. I would keep them updated on the progress of their jobs and let them know if there are any delays.

6. What safety precautions do you take when operating a masking machine?

I take the following safety precautions when operating a masking machine:

- I always wear appropriate personal protective equipment (PPE), such as safety glasses and gloves.

- I make sure that the machine is properly grounded.

- I keep the work area clean and free of debris.

- I never operate the machine while under the influence of alcohol or drugs.

7. How do you ensure the quality of the masked parts?

I ensure the quality of the masked parts by:

- Inspecting the parts before and after masking.

- Using high-quality masking materials.

- Following the manufacturer’s instructions.

- Maintaining the masking machine in good working order.

8. What is your experience with different types of masking machines?

I have experience with a variety of masking machines, including:

- Semi-automatic masking machines

- Automatic masking machines

- CNC masking machines

I am also familiar with the different types of masking materials and their applications.

9. What is your understanding of the role of a masking machine operator?

The role of a masking machine operator is to operate masking machines to apply masking materials to parts. Masking materials are used to protect parts from damage during various processes, such as painting and welding.

Masking machine operators must be able to operate the machine safely and efficiently. They must also be able to inspect the parts before and after masking to ensure the quality of the job.

10. What are your career goals?

My career goals are to become a skilled masking machine operator and to eventually move into a supervisory role. I am eager to learn more about the masking process and to use my skills to contribute to the success of the company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Masking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Masking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Masking Machine Operators are crucial for the smooth functioning of industrial processes and ensuring product quality. Here are the key responsibilities they undertake:1. Masking Machine Operation

Operators are responsible for the efficient operation of masking machines, which involve:

- Loading and unloading parts into the machine.

- Selecting and installing appropriate masking materials.

- Setting machine parameters and monitoring its performance.

2. Quality Control

Ensuring the quality of masked parts is paramount. Operators are responsible for:

- Inspecting parts before and after masking for defects.

- Identifying and correcting any problems with masking materials or machine settings.

- Maintaining quality records and adhering to quality standards.

3. Machine Maintenance

Regular maintenance is essential to maintain the machine’s performance. Operators perform tasks such as:

- Cleaning and lubricating the machine regularly.

- Troubleshooting and resolving minor machine issues.

- Reporting major repairs or malfunctions to supervisors.

4. Production Management

Operators assist in managing production processes by:

- Monitoring production rates and identifying bottlenecks in the masking process.

- Working with supervisors to optimize production schedules and improve efficiency.

- Maintaining inventory of masking materials and supplies.

Interview Tips

To ace the interview for a Masking Machine Operator position, candidates should prepare thoroughly and present themselves confidently. Here are some tips:1. Research the Company and Industry

Before the interview, research the company, its products, and the specific industry it operates in. This knowledge will help you understand the role’s context and ask informed questions.

2. Review Key Responsibilities

Familiarize yourself with the key responsibilities outlined in the job description. Highlight your relevant skills and experience that align with each responsibility. Prepare specific examples to demonstrate your abilities.

3. Practice Common Interview Questions

Anticipate common interview questions such as “Tell me about your experience in operating masking machines” or “How do you ensure the quality of masked parts?” Practice your answers, providing clear and concise explanations.

4. Showcase Technical Skills

Emphasize your technical skills in operating and maintaining masking machines. If possible, quantify your accomplishments by providing specific metrics or examples. This will demonstrate your proficiency in the role.

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to show your interest and engagement. This could include inquiries about the company’s quality control standards, production goals, or opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Masking Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.