Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mast Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

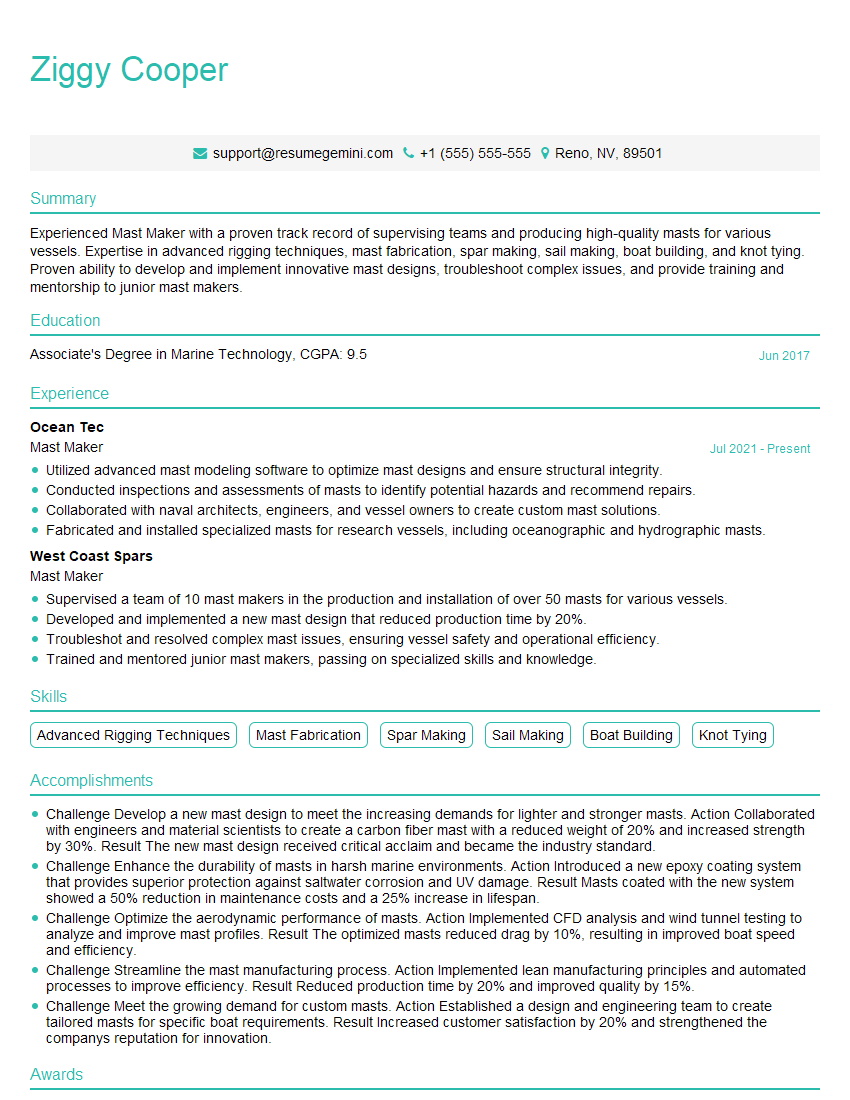

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mast Maker

1. What is the primary role of a Mast Maker?

As a Mast Maker, my primary role would be to design, build, and maintain masts and other spars for sailing vessels. This involves working with various materials, such as wood, fiberglass, and carbon fiber, and utilizing specialized tools and techniques to ensure the structural integrity and functionality of these components.

2. Describe the key steps involved in designing a mast.

Understanding Design Requirements

- Consult with the boat designer or owner to determine the intended use, size, and performance specifications of the mast.

- Calculate the loads and forces that the mast will experience based on the vessel’s design and operating conditions.

Structural Design

- Select appropriate materials and determine the dimensions and shape of the mast based on the calculated loads.

- Design the mast’s internal structure, including spars, spreaders, and reinforcements, to ensure strength and stability.

Detailing and Documentation

- Create detailed drawings and specifications for the mast, outlining its dimensions, materials, and construction methods.

- Prepare production documentation, including assembly instructions and quality control procedures.

3. What factors should be considered when selecting materials for mast construction?

- Strength: The material must be able to withstand the high stresses and loads experienced by the mast.

- Weight: The material should be lightweight to minimize the overall weight of the mast and improve the vessel’s performance.

- Durability: The material must be resistant to corrosion, weathering, and other environmental factors.

- Cost: The cost of the material and the manufacturing process must be taken into consideration.

4. Describe the different types of wood used in mast making and their respective characteristics.

- Sitka Spruce: Known for its strength, stiffness, and light weight, it is commonly used for racing masts.

- Douglas Fir: A durable and strong wood, suitable for masts of large vessels and those subject to heavy loads.

- Western Red Cedar: A naturally decay-resistant wood, often used for masts in coastal areas or on vessels that are stored in humid environments.

- Laminated Veneer Lumber (LVL): Made from thin layers of wood glued together, LVL provides exceptional strength and stability.

5. Explain the process of laminating wood for mast construction.

- Select and prepare thin strips of wood, ensuring straight grain and minimal defects.

- Apply adhesive to one surface of each strip.

- Stack the strips in a specific orientation to achieve the desired strength and stiffness.

- Pressurize the stack to bond the strips together, creating a solid laminated structure.

6. What are the advantages of using carbon fiber in mast construction?

- Strength: Carbon fiber is incredibly strong and can withstand high loads without deformation.

- Light weight: Carbon fiber is very lightweight, reducing the overall weight of the mast and improving the vessel’s performance.

- Stiffness: Carbon fiber masts are very stiff, providing excellent support for sails and reducing mast bend.

- Durability: Carbon fiber is resistant to corrosion and weathering, making it suitable for use in harsh marine environments.

7. Describe the different types of mast fittings and their functions.

- Spreaders: Horizontal bars that extend from the mast to provide support for the sails and prevent the mast from bending excessively.

- Halyards: Ropes used to hoist and lower sails and can be internal or external to the mast.

- Reefing lines: Used to reduce the sail area in strong winds, reefing lines are attached to the sails and run through blocks on the mast.

- Masthead fittings: Include lights, antennas, and other equipment mounted at the top of the mast.

8. Explain the importance of regular maintenance for masts.

- Safety: Regular maintenance ensures that the mast is in good condition and safe to use, preventing failures and accidents.

- Longevity: Proper maintenance extends the lifespan of the mast by protecting it from damage and wear.

- Performance: Well-maintained masts function optimally, providing support for sails and maximizing the vessel’s performance.

9. What are the common signs of mast damage and how should they be addressed?

- Cracks or splits: These can occur due to excessive loads or impact and require immediate repair by a qualified professional.

- Corrosion: Rust or pitting can weaken the mast and should be addressed by sanding, cleaning, and applying protective coatings.

- Loose fittings: Bolts, screws, and other fittings can loosen over time and should be checked and tightened regularly.

- Warping or bending: Excessive bending or warping can indicate structural damage and should be inspected by an expert.

10. Describe your experience with using computer-aided design (CAD) software in mast making.

In my previous role, I utilized CAD software extensively for mast design and engineering. I am proficient in using software such as AutoCAD, SolidWorks, and Rhinoceros to create detailed 3D models and generate production drawings. CAD allows me to optimize mast designs, perform stress analysis, and ensure compliance with industry standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mast Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mast Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mast Makers are skilled professionals specializing in constructing, installing, and maintaining masts and other marine structures. Their expertise extends to the design, fabrication, and repair of masts, spars, and booms utilized in various sailing vessels, from small sailboats to substantial commercial ships.

1. Mast Design and Fabrication

Mast Makers are involved in the conception and execution of mast designs. They work closely with naval architects, engineers, and customers to determine the optimal mast specifications, materials, and configurations. They are responsible for creating detailed plans and drawings, ensuring the masts meet the intended performance and safety criteria.

- Conduct structural analysis and calculations to determine mast dimensions, material requirements, and load-bearing capacity.

- Select and source high-quality materials, such as carbon fiber, aluminum, and wood, for mast construction.

- Utilize specialized tools and techniques, including welding, laminating, and shaping, to fabricate masts.

2. Mast Installation and Rigging

Mast Makers are responsible for the safe and efficient installation of masts on sailing vessels. They collaborate with shipbuilders and rigging crews to ensure the masts are correctly positioned, secured, and aligned. They also perform rigging, installing sails, lines, and other components essential for the operation of the vessel.

- Work at heights to install masts, spars, and booms on vessels.

- Carry out rigging operations, including the installation of sails, lines, and blocks.

- Tune and adjust rigging to optimize vessel performance and safety.

3. Mast Maintenance and Repair

Mast Makers provide ongoing maintenance and repair services to ensure the longevity and reliability of masts. They inspect masts regularly, identifying any signs of damage or wear. They perform necessary repairs, replacing or reinforcing damaged sections, and refinishing surfaces to protect against corrosion and the elements.

- Conduct regular inspections of masts to assess their condition.

- Repair or replace damaged mast sections using appropriate materials and techniques.

- Perform maintenance tasks, such as cleaning, polishing, and applying protective coatings.

4. Safety and Regulations

Mast Makers prioritize safety in all aspects of their work. They adhere to industry standards and regulations, ensuring that masts are designed, installed, and maintained in accordance with established safety codes. They conduct risk assessments, implement safety measures, and provide training to promote a safe work environment.

- Follow established safety protocols and regulations.

- Conduct risk assessments and implement safety measures to minimize hazards.

- Provide training and guidance on safe mast handling and maintenance.

Interview Tips

Preparing thoroughly for a Mast Maker interview can significantly enhance your chances of success. Here are some valuable tips and strategies to help you ace the interview and showcase your skills and qualifications:

1. Research the Company and Position

Demonstrate your interest and enthusiasm by conducting thorough research on the company and the specific Mast Maker role. Familiarize yourself with their history, products or services, and any recent industry news or developments. This knowledge will enable you to ask informed questions and tailor your answers to the company’s needs and aspirations.

- Visit the company’s website to gather information about their business, values, and current projects.

- Review industry publications and news articles to stay abreast of advancements in mast design and fabrication.

- Connect with individuals in the industry through networking or online platforms to gain insights into the company and the role.

2. Highlight Your Skills and Experience

During the interview, confidently articulate your skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to provide tangible evidence of your contributions. Emphasize your expertise in mast design, fabrication, installation, and maintenance, using specific examples to illustrate your capabilities.

- Describe your involvement in notable mast projects, highlighting your role in designing, building, or repairing masts.

- Discuss your proficiency in using industry-standard tools and techniques for mast construction and rigging.

- Share your experience in conducting mast inspections, identifying damage, and implementing repairs or maintenance.

3. Showcase Your Passion and Dedication

Conveying your passion for your craft and dedication to delivering exceptional results can leave a lasting impression on the interviewers. Share anecdotes or examples that demonstrate your commitment to safety, attention to detail, and problem-solving. Express your enthusiasm for working in the marine industry and your eagerness to contribute to the company’s success.

- Describe a situation where you went above and beyond to resolve a mast-related issue, ensuring the safety and satisfaction of a customer.

- Explain how you stay updated on the latest industry advancements and best practices in mast making.

- Share your thoughts on emerging trends in mast design and how they may impact the industry.

4. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the opportunity. Prepare a list of questions that show you are genuinely interested in the company, the role, and the industry. These questions should be specific, relevant, and tailored to the company’s business and your career goals.

- Inquire about the company’s approach to mast design and innovation.

- Ask about the company’s commitment to safety and sustainability in mast manufacturing.

- Express your interest in learning about the company’s growth plans and how you can contribute to them.

5. Follow Up and Express Gratitude

Following up after the interview is a professional courtesy that can reinforce your interest in the position. Send a thank-you note to the interviewers within 24 hours, expressing your appreciation for their time and consideration. Briefly reiterate your key skills and qualifications, and express your enthusiasm for the opportunity. Additionally, if you have any additional information or references that support your application, consider including them in your follow-up.

- Thank the interviewers for their time and the opportunity to discuss the role.

- Reiterate your interest in the position and the company.

- Provide any additional information or references that may strengthen your application.

Next Step:

Now that you’re armed with the knowledge of Mast Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mast Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini