Are you gearing up for an interview for a Master Control Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Master Control Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

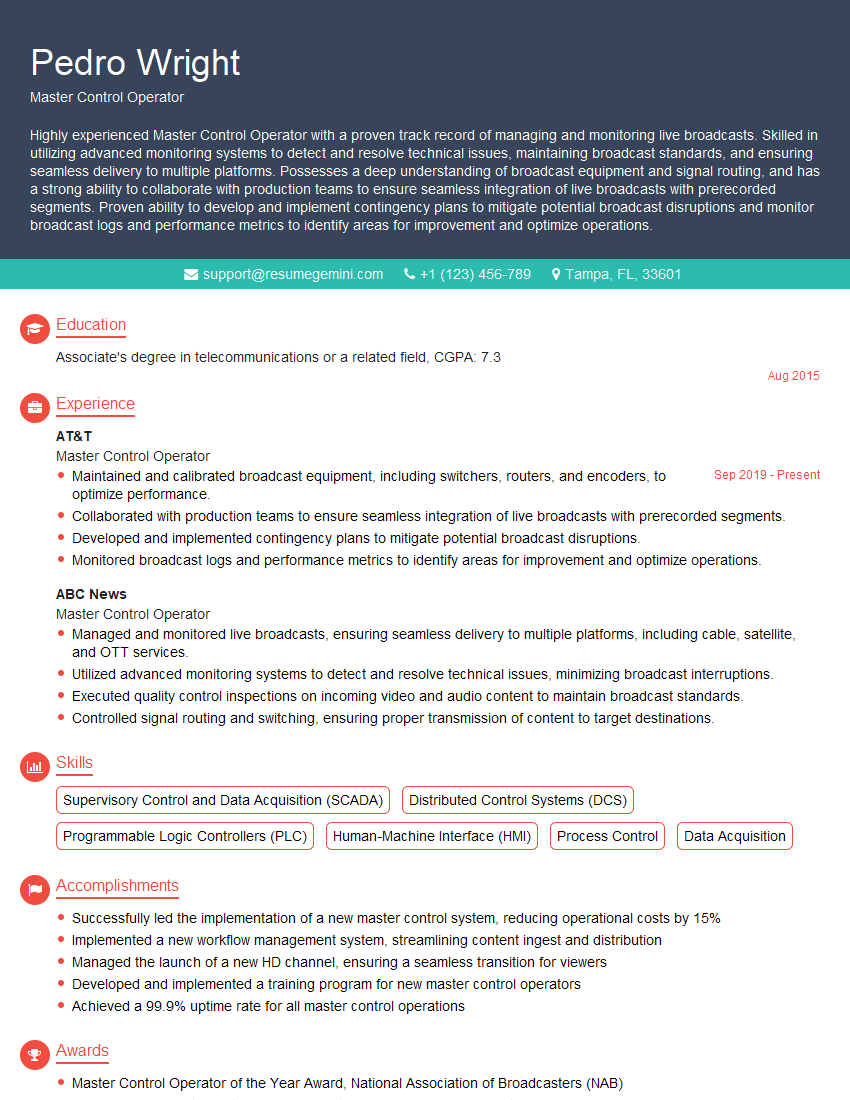

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Master Control Operator

1. How would you define the role and responsibilities of a Master Control Operator (MCO) in a production environment?

The MCO plays a critical role in production environment by:

- Monitoring and controlling all aspects of the production process, ensuring compliance with SOPs and regulations.

- Coordinating with various departments, including engineering, maintenance, and quality control, to ensure smooth operations.

- Responding promptly to alarms, deviations, and emergency situations, taking appropriate corrective actions.

- Documenting all events and actions taken, maintaining accurate records for compliance and auditing purposes.

- Providing training and support to other operators, ensuring a high level of operational proficiency.

2. Describe the key technical skills and knowledge required to be an effective MCO.

Technical Skills:

- Proficient in operating and maintaining production equipment, including PLCs, SCADA systems, and DCS.

- Strong understanding of process control principles, such as PID loops, feedback control, and process optimization.

- Ability to interpret and analyze process data, identify trends, and make informed decisions.

- Expertise in troubleshooting and resolving equipment malfunctions, process deviations, and production bottlenecks.

- Proficient in using computerized maintenance management systems (CMMS).

Knowledge:

- Thorough understanding of the production process, including raw materials, process parameters, and finished product specifications.

- Knowledge of relevant industry standards, regulations, and safety protocols.

- Understanding of quality control principles and procedures.

- Familiarity with automation and process control technologies.

- Excellent communication and interpersonal skills.

3. How would you approach a situation where multiple alarms are triggered simultaneously in the control room?

In such a situation, I would:

- Maintain composure and prioritize the most critical alarms based on their potential impact on safety, production, and quality.

- Acknowledge the alarms promptly to prevent further escalation.

- Analyze the data and identify the root cause of the alarms.

- Take immediate corrective actions to address the most critical alarms first.

- Communicate the situation clearly to relevant personnel, such as supervisors, engineers, and maintenance technicians.

- Document all actions taken and keep a record of the event for future reference.

4. What are the key performance indicators (KPIs) that you would track and monitor as an MCO?

As an MCO, I would track and monitor the following KPIs:

- Production output and efficiency.

- Product quality and yield.

- Equipment uptime and availability.

- Process deviations and downtime.

- Energy consumption and efficiency.

- Safety incidents and near-misses.

- Operator performance and training.

5. How would you handle a situation where there is a conflict between production targets and maintaining quality standards?

In such a situation, I would:

- Consult with supervisors and quality control personnel to understand the specific quality requirements.

- Analyze the production process and identify potential areas for improvement without compromising quality.

- Communicate with the production team to emphasize the importance of maintaining quality standards.

- Implement process adjustments and controls to ensure that production targets are met while adhering to quality specifications.

- Monitor the process closely and make necessary adjustments to maintain both production and quality.

6. Describe your approach to shift handover and ensuring continuity of operations.

My approach to shift handover involves:

- Providing a comprehensive overview of the current production status, process parameters, and any ongoing issues.

- Reviewing any pending tasks, maintenance requests, or upcoming events.

- Documenting all relevant information in the handover logbook.

- Answering any questions or concerns from the incoming operator.

- Ensuring that the incoming operator is fully aware of the situation and is prepared to take over.

7. How do you keep up with advancements in automation and process control technologies?

To stay up-to-date with advancements in automation and process control technologies, I:

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Participate in online forums and discussions.

- Collaborate with vendors and technology providers.

- Take advantage of training opportunities provided by my employer.

8. How would you approach a situation where you need to train and mentor a new operator?

When training and mentoring a new operator, I would:

- Develop a structured training plan based on the operator’s experience and learning objectives.

- Provide hands-on training in the control room and on the production floor.

- Explain the principles of process control and the operation of equipment.

- Supervise the operator and provide feedback on their performance.

- Monitor their progress and provide additional support as needed.

9. How do you handle stress and pressure in a fast-paced production environment?

To handle stress and pressure in a fast-paced production environment, I:

- Maintain composure and focus on the task at hand.

- Prioritize tasks and delegate responsibilities when necessary.

- Take breaks and step away from the control room to clear my head.

- Communicate with supervisors and colleagues to share the workload.

- Practice relaxation techniques, such as deep breathing and meditation.

10. Can you describe your experience in implementing process improvements and optimizing production efficiency?

In my previous role as an MCO, I was involved in several process improvement initiatives:

- Analyzed production data to identify bottlenecks and areas for optimization.

- Suggested process modifications and equipment upgrades to improve efficiency.

- Collaborated with engineers to implement process control enhancements.

- Developed and implemented standard operating procedures to ensure consistent operations.

- Trained operators on new processes and procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Master Control Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Master Control Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Monitoring and maintaining broadcast equipment

Master Control Operators must monitor and maintain all of the equipment used in the broadcast process. This includes cameras, microphones, audio mixers, and video switchers. They must ensure that all of the equipment is working properly and that it is calibrated correctly.

2. Switching between cameras and other sources

Master Control Operators must switch between cameras and other sources during the broadcast. They must do this in a seamless and timely manner so that the audience does not notice any interruptions.

3. Monitoring audio levels

Master Control Operators must monitor the audio levels of the broadcast. They must ensure that the audio is clear and that it is not too loud or too soft.

4. Inserting commercials and other content

Master Control Operators must insert commercials and other content into the broadcast. They must do this at the correct times and in the correct order.

5. Troubleshooting technical problems

Master Control Operators must troubleshoot any technical problems that occur during the broadcast. They must be able to identify the problem and fix it quickly so that the broadcast can continue without interruption.

Interview Tips

Preparing for an interview for a Master Control Operator position can be daunting, but with the right preparation, you can ace the interview and land the job. Here are a few tips to help you prepare:

1. Research the company and the position

Before you go to your interview, it is important to research the company and the position. This will help you understand the company’s culture and what they are looking for in a Master Control Operator. You can find information about the company on their website and in press releases. You can also find information about the position in the job description.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked in an interview for a Master Control Operator position. It is important to practice answering these questions so that you can do so confidently and concisely. Some common interview questions include:

- Tell me about your experience in broadcast operations.

- What are your strengths and weaknesses as a Master Control Operator?

- How do you handle stress and pressure?

- What are your career goals?

3. Be prepared to talk about your technical skills

In an interview for a Master Control Operator position, you will need to be prepared to talk about your technical skills. This includes your experience with broadcast equipment and software. You should also be able to discuss your troubleshooting skills.

4. Be enthusiastic and professional

It is important to be enthusiastic and professional during your interview. This will show the interviewer that you are interested in the position and that you are serious about your career. You should also be polite and respectful to the interviewer.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Master Control Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Master Control Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.