Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Master Lay Out Specialist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

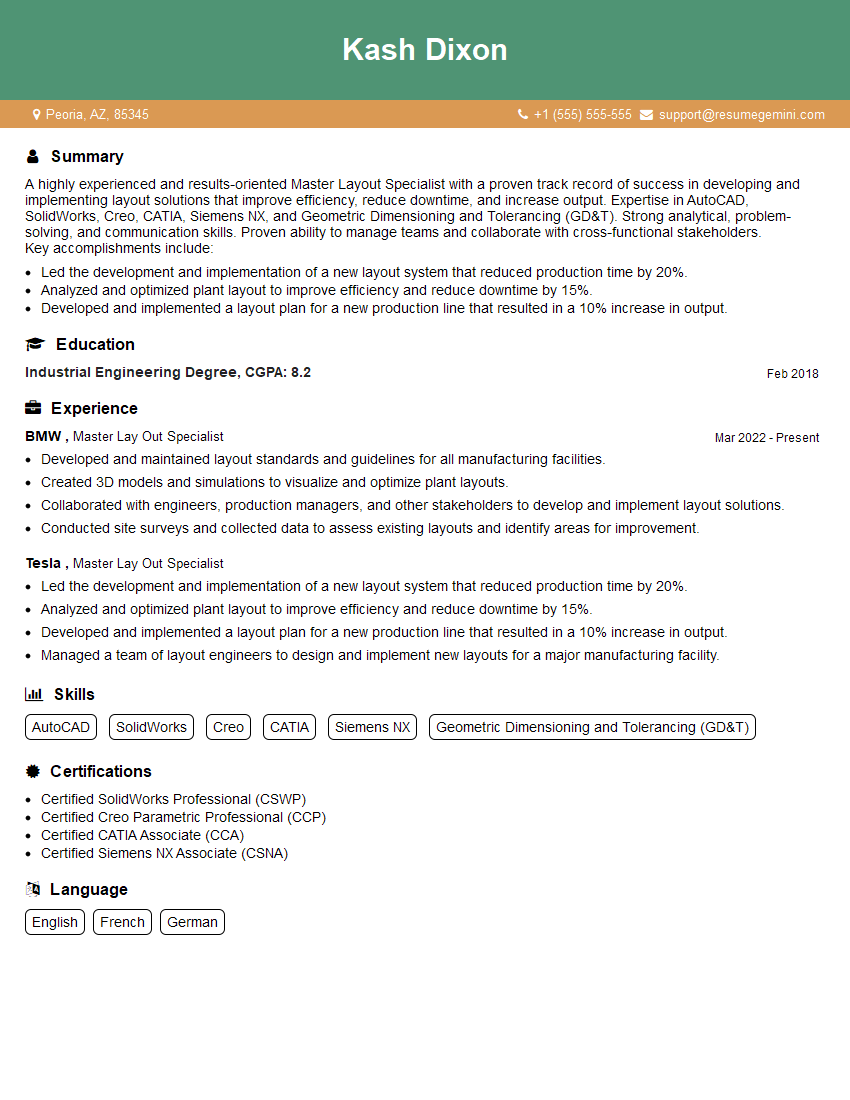

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Master Lay Out Specialist

1. What are the key responsibilities of a Master Lay Out Specialist?

As a Master Lay Out Specialist, my key responsibilities would include:

- Developing and implementing layout plans for production facilities to maximize efficiency and space utilization.

- Conducting time and motion studies to identify areas for improvement in production processes.

- Collaborating with engineers, architects, and production managers to design and optimize plant layouts.

- Ensuring compliance with safety regulations and ergonomic principles in the design of production layouts.

- Staying abreast of industry best practices in layout design and equipment utilization.

2. What are the different types of layout designs and when are they appropriate to use?

Process Layout

- Suitable for high-volume production of similar products.

- Machines and equipment are arranged according to the sequence of operations.

- Minimizes material handling and transportation costs.

Product Layout

- Used for low-volume production of a wide variety of products.

- Machines and equipment are arranged according to the product being produced.

- Provides flexibility and customization options.

Fixed-Position Layout

- Suitable for products that are too large or heavy to move.

- Equipment and workstations are brought to the product.

- Minimizes material handling and transportation costs.

Cellular Layout

- Used to improve productivity and reduce lead times.

- Machines and equipment are arranged into cells based on product families or processes.

- Reduces work-in-progress inventory and improves product quality.

Combination Layout

- Combines elements of different layout types to meet specific production requirements.

- Provides flexibility and efficiency while addressing unique product and process needs.

3. What are the key factors to consider when designing a production layout?

- Production volume and product mix

- Equipment and space requirements

- Material flow and handling

- Safety and ergonomic considerations

- Capacity and expansion plans

- Availability and cost of resources

4. How do you stay up-to-date on the latest trends and best practices in layout design?

- Attend industry conferences and workshops

- Read trade publications and research journals

- Network with other professionals in the field

- Participate in professional development courses and certifications

- Utilize online resources such as webinars and discussion forums

5. What are some of the challenges you have faced in your previous role as a Master Lay Out Specialist?

- Designing a layout for a new production facility with limited space constraints

- Identifying and resolving bottlenecks in an existing production line

- Collaborating with a team of engineers and architects to optimize a complex layout design

- Ensuring compliance with safety regulations while maximizing production efficiency

- Balancing the needs of multiple stakeholders with varying priorities

6. What are some of the most successful layout designs you have implemented?

- Designed a cellular layout for a manufacturing plant, which reduced production lead times by 20%

- Implemented a combination layout in a warehouse, which improved space utilization by 30%

- Optimized the layout of an assembly line, which increased production capacity by 15%

7. How do you measure the effectiveness of a layout design?

- Production output and efficiency

- Lead times and work-in-progress inventory

- Space utilization and material handling costs

- Safety and ergonomic factors

- Employee satisfaction and feedback

8. What are some of the software tools that you are proficient in using for layout design?

- AutoCAD

- SolidWorks

- Plant Simulation

- Ergonomic analysis software

9. What are your strengths and weaknesses as a Master Lay Out Specialist?

Strengths

- Strong technical skills in layout design and production planning

- Excellent communication and interpersonal skills

- Ability to collaborate effectively with cross-functional teams

- Attention to detail and commitment to quality

Weaknesses

- Limited experience in automation and robotics

- Need to stay updated on the latest technological advancements in the field

10. Why are you interested in working as a Master Lay Out Specialist for our company?

- I am impressed by your company’s reputation for innovation and excellence in manufacturing.

- I believe my skills and experience would be a valuable asset to your team.

- I am eager to contribute to the success of your company by optimizing production layouts and improving overall efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Master Lay Out Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Master Lay Out Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Master Lay Out Specialist is responsible for developing and maintaining the layout of a manufacturing facility. This includes planning and arranging the placement of equipment, machinery, and other resources to optimize efficiency and productivity. Key job responsibilities include:1. Develop and Maintain Facility Layouts

* Create and update facility layouts using CAD software or other tools * Ensure that layouts meet all safety, ergonomic, and efficiency requirements * Consult with engineers, architects, and other stakeholders to determine equipment placement and workflow2. Optimize Equipment Placement

* Determine the most efficient placement of equipment to minimize downtime and improve production flow * Consider factors such as equipment size, shape, and capacity when planning layout * Ensure that equipment is accessible for maintenance and repairs3. Improve Productivity

* Identify and implement layout changes that can improve productivity and reduce costs * Analyze workflow and identify areas for improvement * Use data and metrics to measure the effectiveness of layout changes4. Ensure Safety and Ergonomics

* Design layouts that meet all safety regulations and ergonomic standards * Ensure that equipment is properly guarded and that there is adequate space for workers to move around safely * Incorporate ergonomic principles into layout design to reduce the risk of injuries and fatigueInterview Tips

To ace the interview for a Master Lay Out Specialist position, candidates should prepare thoroughly and demonstrate their skills and experience in the following areas:1. Technical Skills

* Proficiency in CAD software and other layout design tools * Understanding of manufacturing processes and equipment * Familiarity with safety and ergonomic standards2. Problem-Solving and Analytical Skills

* Ability to identify and solve problems related to facility layout * Strong analytical skills to evaluate data and identify areas for improvement * Creativity and innovation in finding solutions3. Communication and Interpersonal Skills

* Excellent communication skills to present ideas and collaborate with engineers, architects, and other stakeholders * Strong interpersonal skills to build relationships and work effectively in a team environment4. Industry Knowledge

* Knowledge of best practices in facility layout design * Understanding of the latest trends and technologies in the manufacturing industry * Awareness of industry standards and regulationsNext Step:

Now that you’re armed with the knowledge of Master Lay Out Specialist interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Master Lay Out Specialist positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini