Feeling lost in a sea of interview questions? Landed that dream interview for Master Machinist but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Master Machinist interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

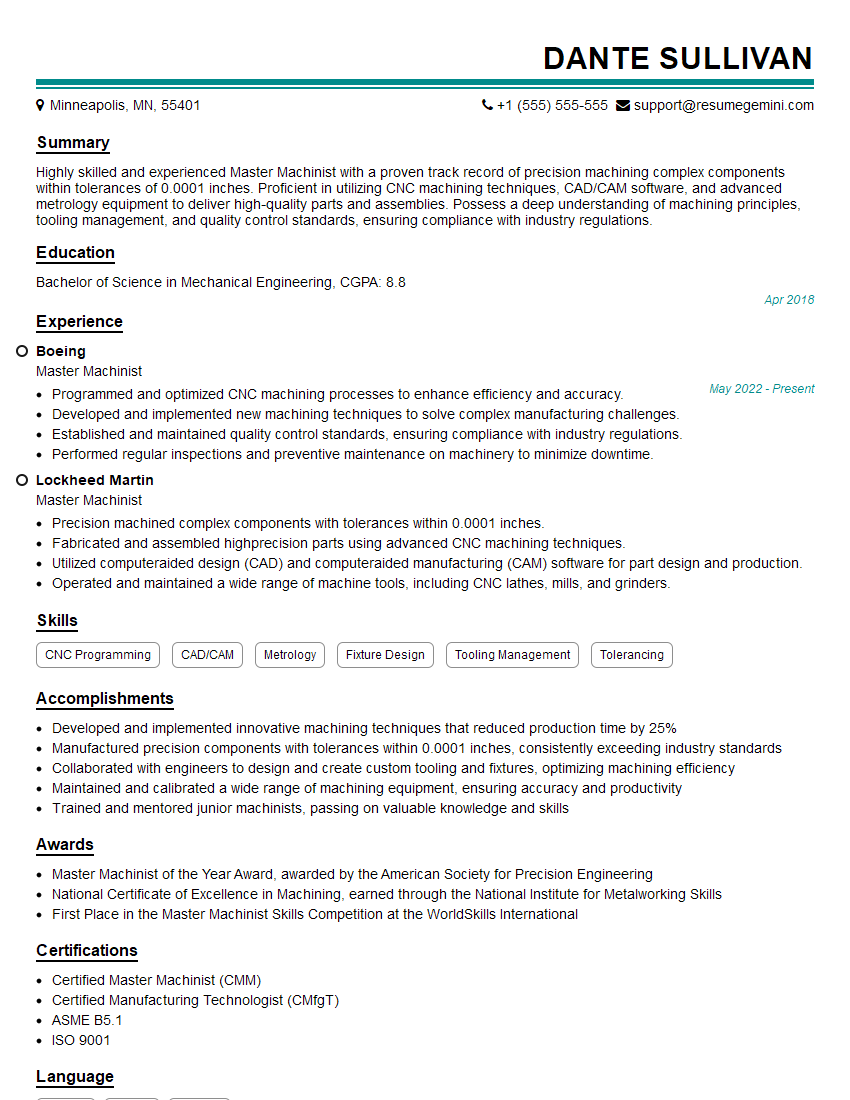

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Master Machinist

1. What are the different types of machining operations?

Some common types of machining operations include:

- Turning

- Milling

- Drilling

- Grinding

- Boring

- Shaping

- Planing

- Slotting

- Broaching

2. What are the most important factors to consider when selecting a cutting tool?

Material of the workpiece

- The material of the workpiece will affect the type of cutting tool required.

- For example, harder materials require harder cutting tools.

Operation being performed

- The operation being performed will also affect the type of cutting tool required.

- For example, different cutting tools are used for turning, milling, and drilling.

Desired surface finish

- The desired surface finish will also affect the type of cutting tool required.

- For example, a finer surface finish requires a sharper cutting tool.

3. What are the different types of CNC machines?

Some common types of CNC machines include:

- CNC mills

- CNC lathes

- CNC routers

- CNC plasma cutters

- CNC waterjet cutters

- CNC laser cutters

4. What are the advantages of using CNC machines?

Some of the advantages of using CNC machines include:

- Increased accuracy and precision

- Reduced setup time

- Increased productivity

- Reduced labor costs

- Improved safety

5. What are the different types of CAM software?

Some common types of CAM software include:

- Mastercam

- SolidWorks CAM

- NX CAM

- Creo Parametric CAM

- CATIA CAM

6. What are the most important factors to consider when selecting a CAM software package?

Some of the most important factors to consider when selecting a CAM software package include:

- The type of machining operations you need to perform

- The complexity of the parts you need to machine

- The size of your budget

- The level of support you need

- The user-friendliness of the software

7. What are the different types of G-codes?

Some common types of G-codes include:

- G00: Rapid positioning

- G01: Linear interpolation

- G02: Circular interpolation clockwise

- G03: Circular interpolation counterclockwise

- G04: Dwell

- G28: Return to home

- G90: Absolute positioning

- G91: Incremental positioning

8. What are the different types of M-codes?

Some common types of M-codes include:

- M00: Program stop

- M01: Optional program stop

- M02: End of program

- M03: Spindle on clockwise

- M04: Spindle on counterclockwise

- M05: Spindle off

- M06: Tool change

- M08: Coolant on

- M09: Coolant off

9. What are the different types of CNC controllers?

Some common types of CNC controllers include:

- Open-loop controllers

- Closed-loop controllers

- Proportional-integral-derivative (PID) controllers

- Adaptive controllers

10. What are the most important factors to consider when selecting a CNC controller?

Some of the most important factors to consider when selecting a CNC controller include:

- The type of CNC machine you have

- The number of axes you need to control

- The speed and accuracy you need

- The level of support you need

- The price

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Master Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Master Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Master Machinists are highly skilled professionals who are responsible for operating and maintaining complex machinery. They use their knowledge of engineering principles and machining techniques to produce high-quality parts and components.

1. Set up and operate CNC machines

Master Machinists use computer-aided software to program and operate CNC machines. They must have a deep understanding of how these machines work and how to use them to create precise parts.

- Program CNC machines to create complex parts and components.

- Operate CNC machines to produce high-quality parts and components.

2. Inspect and maintain machinery

Master Machinists are also responsible for inspecting and maintaining machinery. They must be able to identify potential problems and take steps to correct them.

- Inspect machinery for wear and tear.

- Perform maintenance on machinery to keep it in good working order.

3. Troubleshoot and repair machinery

Master Machinists must be able to troubleshoot and repair machinery when problems occur. They must be able to identify the source of the problem and take steps to correct it.

- Troubleshoot machinery problems.

- Repair machinery to keep it in good working order.

4. Prepare and interpret engineering drawings

Master Machinists must be able to read and interpret engineering drawings. They must be able to use these drawings to create parts and components that meet the specifications.

- Read and interpret engineering drawings.

- Use engineering drawings to create parts and components.

5. Work with other team members on projects

Master Machinists often work with other team members on projects. They must be able to communicate effectively and work together to achieve common goals.

- Work with other team members on projects.

- Communicate effectively with other team members.

Interview Tips

Here are some tips to help you ace your interview for a Master Machinist position:

1. Research the company and the position

Before you go on the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a Master Machinist.

- Visit the company’s website to learn about their products and services.

- Read online reviews of the company to get a sense of their culture and reputation.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions so that you can deliver them confidently and clearly.

- Write down your answers to common interview questions.

- Practice your answers out loud so that you can deliver them confidently.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Master Machinist. Be prepared to talk about your past projects and the techniques you used to complete them.

- Bring a portfolio of your work to the interview.

- Be prepared to discuss your experience and skills in detail.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or dress pants and a button-down shirt.

- Arrive for your interview on time.

Next Step:

Now that you’re armed with the knowledge of Master Machinist interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Master Machinist positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini