Are you gearing up for an interview for a Master Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Master Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

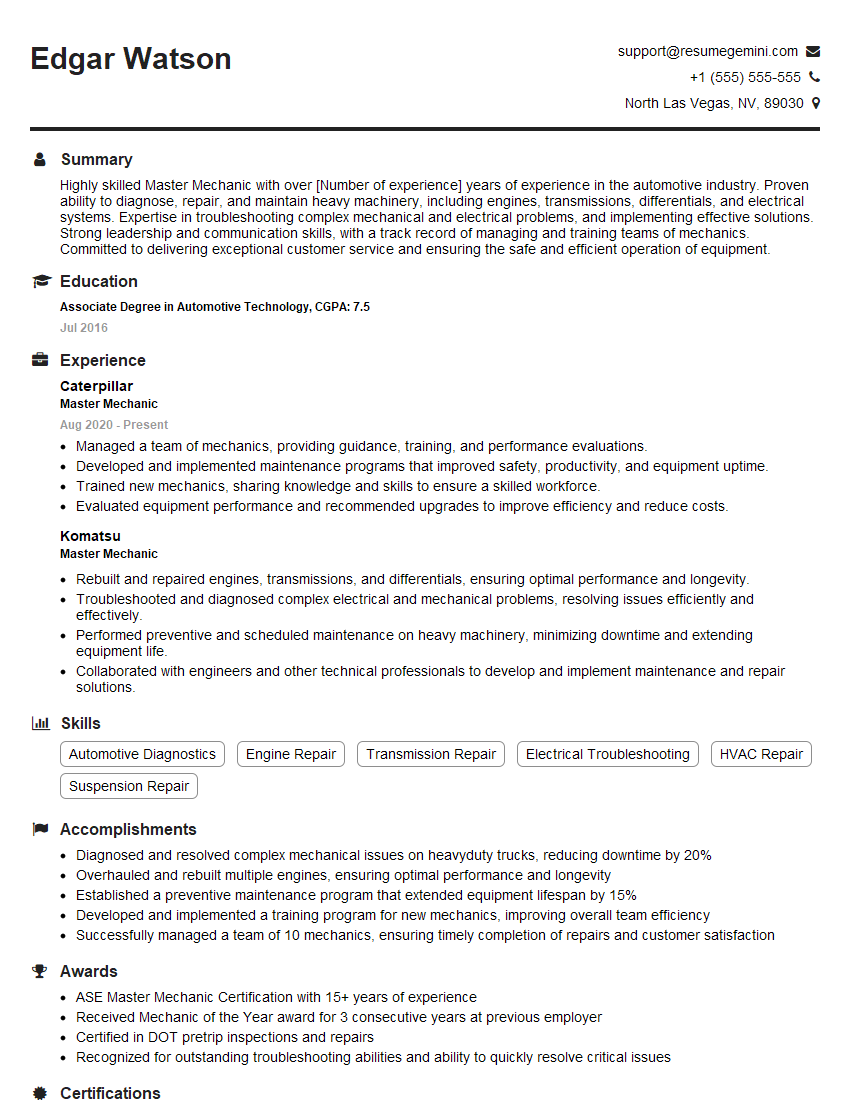

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Master Mechanic

1. What do you know about different types of engine components and how they work together?

An engine consists of several components that work together to convert chemical energy into mechanical energy. The major components of an engine include:

- Cylinder and Piston: The cylinder is a cylindrical chamber in which the piston moves up and down. The piston is connected to the crankshaft through a connecting rod.

- Cylinder Head: The cylinder head seals the top of the cylinder and contains the valves that control the flow of air and fuel into and out of the cylinder.

- Camshaft: The camshaft is a shaft that controls the opening and closing of the valves.

- Crankshaft: The crankshaft is a shaft that converts the reciprocating motion of the piston into rotary motion.

2. Explain the working principle of a diesel engine and how it differs from a gasoline engine?

Fuel Injection

- Diesel engines use direct fuel injection, where fuel is injected directly into the cylinder.

- Gasoline engines use port fuel injection, where fuel is injected into the intake manifold.

Compression Ratio

- Diesel engines have higher compression ratios (typically 14:1 to 20:1) than gasoline engines (typically 8:1 to 12:1).

- The higher compression ratio in diesel engines results in higher thermal efficiency.

Ignition

- Diesel engines rely on compression ignition, where the heat generated by the high compression ignites the fuel.

- Gasoline engines use spark plugs for ignition.

3. How do you troubleshoot a vehicle that is experiencing engine misfires?

- Check for spark: Use a spark tester to check if the spark plugs are firing.

- Check for fuel: Check if the fuel injectors are delivering fuel to the cylinders.

- Check for compression: Perform a compression test to check if the cylinders are sealing properly.

- Check for vacuum leaks: Inspect the intake and exhaust manifolds for any leaks.

- Check for electrical problems: Check the wiring, sensors, and electronic control modules for any faults.

4. Describe the procedure for performing a transmission fluid change.

- Safety first: Park the vehicle on a level surface, engage the parking brake, and allow the engine to cool down.

- Locate the transmission pan: The transmission pan is usually located at the bottom of the transmission.

- Drain the old fluid: Place a drain pan under the transmission pan and remove the drain plug to drain the old fluid.

- Replace the drain plug: Once the fluid has drained, replace the drain plug and tighten it to the specified torque.

- Add new fluid: Use a funnel to add new transmission fluid to the transmission through the dipstick tube.

- Check the fluid level: Start the engine and let it run for a few minutes. Then, check the fluid level on the dipstick and adjust it if necessary.

5. How do you diagnose and repair a vehicle that is experiencing braking problems?

- Check for leaks: Inspect the brake lines, calipers, and wheel cylinders for any leaks.

- Check the brake pads: Inspect the brake pads for wear or contamination.

- Check the brake rotors: Inspect the brake rotors for wear or damage.

- Check the master cylinder: Check the master cylinder for leaks or damage.

- Check the brake booster: Check the brake booster for leaks or damage.

6. Explain the operation of an anti-lock braking system (ABS) and how it improves vehicle safety.

- ABS sensors: ABS sensors monitor the speed of each wheel.

- ABS control module: The ABS control module receives signals from the ABS sensors and determines if any of the wheels are locking up.

- ABS modulator: The ABS modulator controls the brake pressure to each wheel. If the ABS control module detects that a wheel is locking up, it will reduce the brake pressure to that wheel.

- ABS improves vehicle safety: By preventing the wheels from locking up, ABS allows drivers to maintain control of the vehicle during braking. ABS also reduces stopping distances, especially on slippery surfaces.

7. How do you diagnose and repair a vehicle that is experiencing suspension problems?

- Inspect the suspension components: Visually inspect the suspension components, such as the springs, shocks, struts, and control arms, for any damage or wear.

- Check for leaks: Check the shocks and struts for any leaks.

- Perform a bounce test: Push down on the corners of the vehicle and release to check for excessive bouncing or sagging.

- Check the alignment: Check the vehicle’s alignment to ensure that the wheels are properly aligned.

8. Describe the different types of electrical systems used in vehicles and how they work together.

- Starting system: The starting system includes the battery, starter, and ignition switch.

- Charging system: The charging system includes the alternator, battery, and voltage regulator.

- Lighting system: The lighting system includes the headlights, taillights, and interior lights.

- Electrical accessories: Electrical accessories include items such as the radio, power windows, and air conditioning.

9. How do you diagnose and repair a vehicle that is experiencing electrical problems?

- Check the battery: Check the battery voltage and terminals for any corrosion.

- Check the starter: Check the starter for any damage or wear.

- Check the alternator: Check the alternator for any damage or wear.

- Check the wiring: Inspect the wiring for any damage or loose connections.

- Check the fuses and relays: Check the fuses and relays for any blown or damaged components.

10. Describe your experience with using diagnostic equipment to troubleshoot and repair vehicles.

- Scan tools: I have experience using scan tools to read and interpret diagnostic trouble codes.

- Multimeters: I have experience using multimeters to measure voltage, resistance, and current.

- Oscilloscopes: I have experience using oscilloscopes to analyze electrical signals.

- Other diagnostic equipment: I have experience using other diagnostic equipment, such as pressure gauges, vacuum gauges, and leak detectors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Master Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Master Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Master Mechanic, you’ll be responsible for the overall maintenance, repair, and troubleshooting of complex mechanical systems and equipment. Your primary duties will include:

1. Diagnosing and Repairing Mechanical Issues

Identifying malfunctions and defects in machinery, vehicles, or other equipment.

- Performing root cause analysis to determine the source of problems.

- Repairing or replacing faulty components, parts, and systems.

2. Preventive Maintenance and Inspections

Conducting regular inspections and maintenance tasks to prevent equipment breakdowns.

- Replacing filters, fluids, and lubricants.

- Adjusting and calibrating equipment to ensure optimal performance.

3. Overhauling and Rebuilding Equipment

Performing major repairs and overhauls to restore equipment to its original condition.

- Disassembling and reassembling complex mechanical systems.

- Replacing worn-out or damaged parts and components.

4. Troubleshooting and Problem Solving

Identifying and resolving mechanical issues that occur during operations.

- Analyzing system behavior and performance data.

- Developing and implementing solutions to restore equipment functionality.

Interview Tips

To ace your interview for a Master Mechanic position, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s operations and the industry in which they operate. This shows you’ve taken the time to understand their business and are genuinely interested in the role.

- Review the company’s website, annual reports, and industry news.

- Learn about the specific equipment and technologies the company uses.

2. Highlight Your Technical Skills and Expertise

Emphasize your strong foundation in mechanical engineering, repair techniques, and diagnostic tools. Provide specific examples of complex repairs you’ve handled and the results you achieved.

- Quantify your accomplishments with metrics like reduced downtime or improved equipment reliability.

- Discuss your experience with specific equipment or software that is relevant to the role.

3. Showcase Your Problem-Solving Abilities

Interviewers want to know how you approach and solve mechanical issues. Describe situations where you identified and resolved complex problems effectively.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Highlight your analytical skills and ability to think critically.

4. Emphasize Safety and Attention to Detail

Master Mechanics must prioritize safety and adhere to established procedures. Communicate your understanding of safety regulations and your commitment to maintaining a safe work environment.

- Describe your experience with safety protocols and adherence to industry standards.

- Highlight your attention to detail and ability to thoroughly inspect equipment.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Master Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Master Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.