Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Master Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

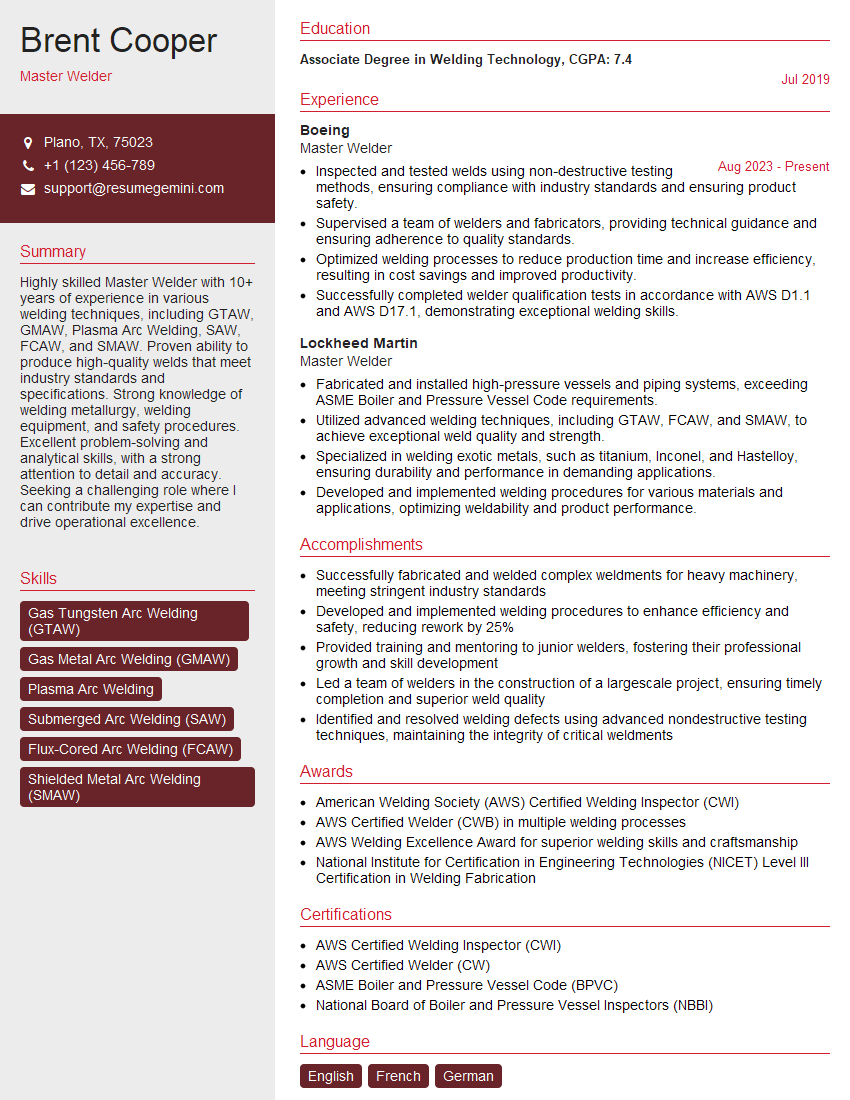

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Master Welder

1. What are the different types of welding processes and which one do you prefer?

There are several types of welding processes, including:

- Arc welding

- Gas welding

- Resistance welding

- Solid-state welding

My preferred welding process is arc welding, specifically gas metal arc welding (GMAW), due to its versatility, efficiency, and ability to produce high-quality welds in various materials.

2. Describe the steps involved in preparing a metal surface for welding.

Surface Cleaning

- Remove dirt, oil, and contaminants using a wire brush, sandpaper, or chemical cleaner.

Edge Preparation

- Bevel or otherwise shape the edges to create a suitable joint design for welding.

Joint Alignment and Clamping

- Align the metal pieces precisely and secure them with clamps or fixtures to maintain the desired joint shape.

3. What are the common welding defects and how can they be prevented?

- Porosity: Use clean materials, shield the weld pool from the atmosphere, and ensure proper welding parameters.

- Cracking: Select appropriate materials, use preheating and post-heating techniques, and control the cooling rate.

- Lack of fusion: Ensure proper joint preparation, use appropriate welding parameters, and check the weld pool for complete fusion.

- Undercut: Use proper welding techniques, select the correct electrode size, and maintain the appropriate welding angle.

4. What is the importance of post-weld heat treatment and when is it necessary?

Post-weld heat treatment (PWHT) is a process that involves heating the welded joint to a specific temperature and holding it for a controlled period of time to achieve desired mechanical properties.

PWHT is typically used to:

- Reduce residual stresses and improve toughness

- Enhance the mechanical strength and hardness of the weldment

- Alter the microstructure and grain structure of the weld and heat-affected zone

PWHT is often required for critical applications, such as pressure vessels, pipelines, and structural components, where high strength and reliability are paramount.

5. What are the different types of welding consumables and how do you select the appropriate one for a given application?

Welding consumables include electrodes, wires, rods, and fluxes, each designed for specific welding processes and materials.

Factors to consider when selecting a welding consumable:

- Base material composition and thickness

- Welding process and desired weld characteristics

- Required mechanical properties, such as strength, toughness, and corrosion resistance

- Welding environment and shielding gas availability

By considering these factors, the appropriate welding consumable can be chosen to optimize the quality and performance of the welded joint.

6. Describe the proper safety precautions that should be taken when welding.

Welding involves potential hazards, so adhering to safety precautions is crucial:

- Wear appropriate personal protective equipment (PPE) including a welding helmet, gloves, and flame-resistant clothing.

- Ensure adequate ventilation and use exhaust systems to remove fumes and gases.

- Secure the work area and isolate electrical cables.

- Inspect equipment regularly and maintain it in good condition.

- Be aware of fire hazards and have firefighting equipment readily available.

7. What are the quality control procedures used to ensure the integrity of welded joints?

- Visual inspection: Examine the weld for any visible defects or imperfections.

- Non-destructive testing (NDT): Use methods like radiography, ultrasonic testing, or magnetic particle inspection to detect internal flaws.

- Destructive testing: Perform tensile tests, bend tests, or impact tests on samples to assess weld strength and ductility.

- Review welding documentation: Verify that welding procedures and parameters were followed as specified.

- Regular in-service inspections: Monitor the performance of welded components over time to identify any potential issues.

8. What is your experience with welding exotic materials, such as titanium or stainless steel?

I have extensive experience welding exotic materials, including titanium and stainless steel, in the aerospace and medical industries. These materials require specialized welding techniques and consumables to achieve optimal results.

For titanium welding, I have mastered techniques such as gas tungsten arc welding (GTAW) and plasma arc welding (PAW) to produce high-quality welds with minimal contamination.

When welding stainless steel, I employ specialized filler materials and welding procedures to prevent sensitization and maintain the desired corrosion resistance.

9. What are the latest advancements in welding technology that you are familiar with?

- Laser welding: High-precision, high-speed welding using focused laser beams.

- Electron beam welding: Deep penetration welding with minimal heat input, often used in high-vacuum environments.

- Robotic welding: Automated welding using robots, improving accuracy, efficiency, and safety.

- Additive manufacturing: Building 3D objects by layering molten material, allowing for complex designs and reduced material waste.

- Virtual reality (VR) training: Immersive training simulations for welders to improve skills and safety.

10. What is your approach to staying updated with the latest welding techniques and best practices?

- Attend industry conferences and workshops.

- Read technical journals and research papers.

- Participate in online forums and discussions.

- Collaborate with other welding professionals and experts.

- Regularly review welding codes and standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Master Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Master Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Master Welders are highly skilled professionals responsible for welding metal structures and components with utmost precision and accuracy. Their key job responsibilities encompass a wide range of duties, including:

1. Welding and Fabrication

Executing welding tasks as per specifications and blueprints, ensuring the structural integrity and quality of welded joints.

- Using advanced welding techniques such as MIG, TIG, and stick welding to join various types of metals.

- Fabricating metal components and structures, such as tanks, vessels, and piping systems, to precise dimensions.

2. Quality Control

Conducting inspections and tests to ensure that welded joints meet industry standards and company specifications.

- Performing non-destructive testing methods (NDT), such as radiography, ultrasonic testing, and visual inspections, to detect any defects or anomalies.

- Maintaining detailed records of welding processes and quality control procedures to ensure traceability and accountability.

3. Maintenance and Repair

Carrying out maintenance and repair work on existing welded structures to maintain their integrity and functionality.

- Inspecting welded joints for signs of wear, corrosion, or damage, and performing necessary repairs.

- Working closely with engineers and other professionals to determine the best repair techniques and materials.

4. Safety and Compliance

Adhering to safety regulations and guidelines to ensure a safe work environment and minimize risks.

- Wearing appropriate protective gear, including welding masks, gloves, and flame-resistant clothing.

- Maintaining a clean and organized work area, minimizing clutter and potential hazards.

Interview Tips

Preparing for a Master Welder interview requires meticulous attention to detail and a thorough understanding of the role’s responsibilities. Here are some essential tips and hacks to help candidates ace the interview:

1. Research the Company and Position

Thoroughly research the company’s industry, products or services, and company culture to demonstrate your interest and knowledge.

- Visit the company website, LinkedIn page, and read industry news articles to gain insights into their operations and values.

- Review the job description carefully, identifying the specific skills, experience, and qualifications required for the role.

2. Highlight Your Skills and Experience

Quantify your accomplishments and emphasize your welding expertise, highlighting your proficiency in various welding techniques and your ability to produce high-quality welds.

- Provide specific examples of projects you have worked on, showcasing your ability to meet deadlines and exceed expectations.

- Mention any certifications or training programs you have completed, demonstrating your commitment to professional development.

3. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. Research potential interview questions and tailor your responses to the specific job description.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing clear examples of your skills and accomplishments.

- Seek feedback from a friend, family member, or career counselor to refine your answers and improve your delivery.

4. Demonstrate Your Safety Knowledge

Emphasize your understanding of welding safety regulations and your commitment to maintaining a safe work environment.

- Discuss your experience in using personal protective equipment (PPE), handling hazardous materials, and following safe welding practices.

- Mention any safety training or certifications you have obtained, demonstrating your commitment to adhering to industry standards.

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to show your interest in the position and the company. This demonstrates your engagement and enthusiasm for the role.

- Inquire about the company’s growth plans, upcoming projects, or training opportunities.

- Seek clarification on any aspects of the job description or company culture that you are curious about.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Master Welder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.