Are you gearing up for a career in Mat Machine Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Mat Machine Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

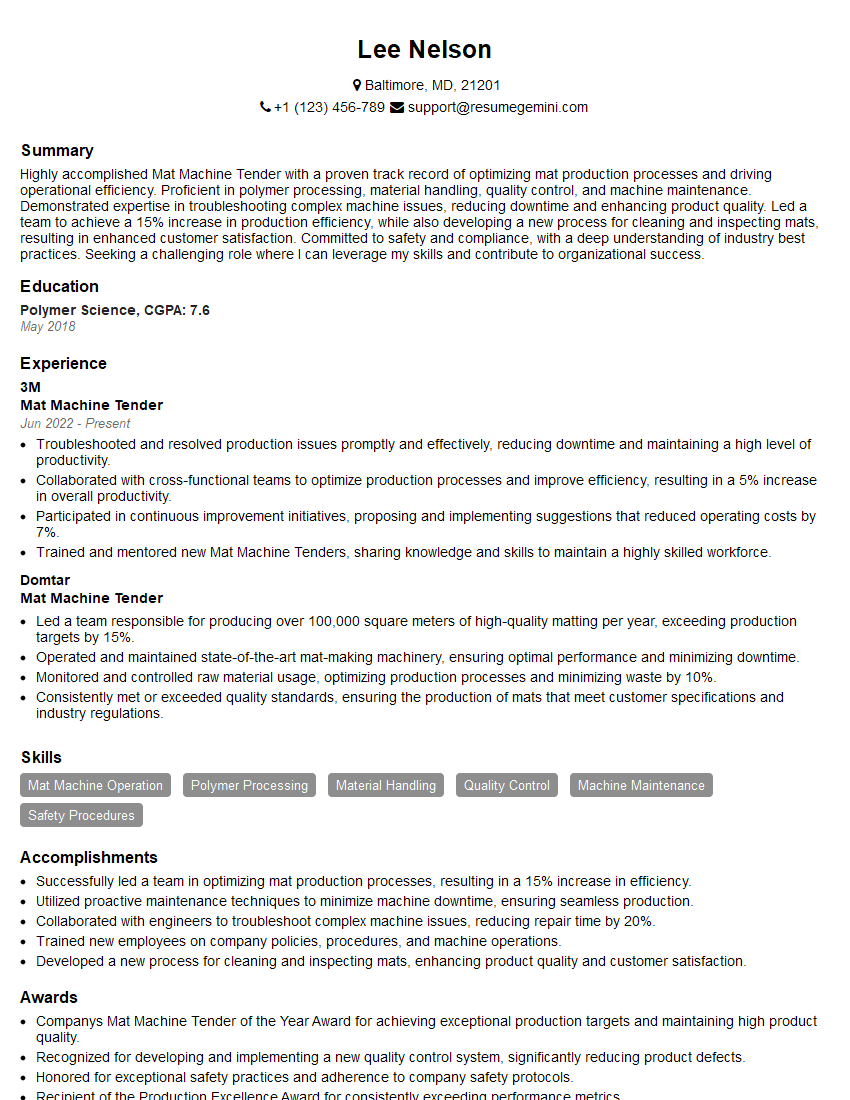

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mat Machine Tender

1. Explain the process of mat forming in detail?

The process of mat forming involves several distinct steps:

- Fiber Preparation: Raw fibers are opened and blended to create a homogeneous mixture. This is crucial for ensuring uniform mat formation and properties.

- Web Formation: The fibers are then formed into a web, which is a thin layer of entangled fibers. The weight and thickness of the web are carefully controlled to meet the desired mat specifications.

- Wet Pressing: The web is passed through a series of rollers to remove excess water. This step helps to consolidate the fibers and increase the mat’s density.

- Drying: The wet mat is then dried using heated air or other methods to remove remaining moisture. This step is critical for achieving the desired mat properties, such as strength and stiffness.

- Calendering: The dried mat is passed through a series of heated rollers to improve its surface finish and properties. This process can enhance the mat’s smoothness, gloss, and mechanical strength.

- Cooling: The calendered mat is cooled to room temperature to stabilize its properties and prepare it for further processing or use.

2. Describe the different types of mats produced on a mat machine and their applications?

- Polyester Mat: Used in fiberglass-reinforced plastics (FRP) applications, such as boat hulls, automotive parts, and construction materials.

- Glass Mat: A high-strength mat used in printed circuit boards (PCBs), composites, and specialized filtration systems.

- Felt Mat: A dense and non-woven mat used in soundproofing, insulation, and filtration applications.

- Tissue Mat: A thin and absorbent mat used in medical dressings, hygiene products, and packaging.

- Scrim Mat: A mat with reinforcing fibers incorporated into it, used in applications requiring high tensile strength, such as roofing and reinforcement tapes.

Applications

- FRP Boat Hulls

- Automotive Body Panels

- Building Cladding

- Medical Supplies

- Filtration Systems

3. What are the key factors that affect the quality of the finished mat?

- Fiber Quality: The type, length, and strength of the fibers used directly impact the mat’s properties.

- Web Formation: The uniformity and consistency of the web influence the mat’s density, thickness, and porosity.

- Wet Pressing: The pressure and dwell time during wet pressing affect the mat’s moisture content and density.

- Drying: The temperature and dwell time during drying determine the mat’s moisture content, strength, and stiffness.

- Calendering: The pressure, temperature, and dwell time during calendering influence the mat’s surface finish, gloss, and mechanical properties.

4. How do you maintain and troubleshoot a mat machine?

Maintaining and troubleshooting a mat machine requires regular preventive maintenance and prompt attention to any issues:

- Preventive Maintenance: Regular cleaning, lubrication, and inspection of components help prevent breakdowns and ensure optimal performance.

- Troubleshooting: In case of issues, identifying the root cause is crucial. Common problems include web breaks, uneven mat formation, and quality defects.

- Maintenance Schedule: A well-defined maintenance schedule helps ensure timely servicing and reduces the risk of major breakdowns.

5. What safety precautions should be taken when operating a mat machine?

- Wear Proper Safety Gear: Protective clothing, gloves, safety glasses, and earplugs must be worn to minimize risks.

- Follow Operating Procedures: Adhering to established operating procedures ensures safe handling of the machine and materials.

- Guard and Barricade Access Points: Access points to moving parts and hazardous areas should be properly guarded to prevent injuries.

- Emergency Stop Button: The emergency stop button must be easily accessible and regularly tested for proper functionality.

- Training and Supervision: Only trained and authorized personnel should operate the mat machine under proper supervision.

6. Explain the role of temperature and humidity control in the mat forming process?

- Temperature: Temperature control is critical during drying to achieve the desired moisture content and properties in the finished mat. Maintaining consistent temperature ensures uniform drying and prevents defects.

- Humidity: Humidity levels can affect the fiber moisture content during web formation and drying. Controlling humidity helps optimize the mat’s properties and prevents issues like uneven drying and brittleness.

7. Describe the difference between thermosetting and thermoplastic mats?

- Thermosetting Mats: These mats are made from fibers that undergo a chemical change upon heating, forming permanent bonds and becoming rigid. They are typically used in high-temperature applications.

- Thermoplastic Mats: These mats are made from fibers that soften upon heating and can be molded or reshaped. They are generally used in applications where flexibility and ease of molding are required.

8. How do you ensure the consistency of mat quality in production?

- Raw Material Quality Control: Ensuring the consistent quality of raw fibers is essential for maintaining mat quality.

- Process Parameter Monitoring: Regularly monitoring and adjusting process parameters, such as temperature, humidity, and web tension, helps maintain consistent production.

- Regular Inspections: Implementing a system of regular inspections and testing allows for early detection and correction of any quality issues.

9. Explain the principles behind the calendering process and its effect on mat properties?

- Pressure and Heat: Calendering involves applying pressure and heat to the mat through a series of rollers.

- Surface Improvement: The pressure and heat help to smooth the mat’s surface, reducing roughness and improving its aesthetics.

- Mechanical Properties: Calendering can enhance the mat’s mechanical properties, such as tensile strength, stiffness, and density.

- Gloss and Finish: The calendering process can also impart a glossy or matte finish to the mat, depending on the desired specifications.

10. How do you optimize mat machine efficiency and minimize downtime?

- Preventive Maintenance: Regular maintenance and timely replacement of worn-out or damaged components help prevent breakdowns and minimize downtime.

- Operator Training: Well-trained operators can handle the machine more efficiently and respond to issues promptly, reducing downtime.

- Spare Parts Inventory: Maintaining an inventory of critical spare parts ensures quick replacements in case of emergencies.

- Production Planning: Optimizing production schedules and minimizing changeovers can reduce downtime and improve efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mat Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mat Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mat Machine Tenders are responsible for monitoring and operating automated machines that produce rubber or plastic mats. They need to have experience in working with various types of materials and be able to troubleshoot issues with equipment to optimize efficiency, quality, and speed.

1. Monitoring Equipment

Mat Machine Tenders constantly observe and monitor the condition of the machine, its components, and the materials being processed. This includes checking for any abnormalities, leaks, blockages, and changes in pressure and temperature.

- Regularly inspects equipment for potential issues, wear and tear, and defects.

- Monitors machine readings and gauges to ensure parameters are within specified ranges.

2. Material Handling

Mat Machine Tenders manage and control the flow of materials throughout the production process. They are responsible for loading and unloading materials, adjusting equipment settings accordingly, and inspecting the quality of the produced mats.

- Loads and unloads raw materials into and out of the machine hopper or storage areas.

- Ensures that the material is properly fed into the machine and that the correct settings are used.

3. Troubleshooting and Maintenance

Mat Machine Tenders have the ability to identify and resolve issues that may arise during production, such as machine jams, material blockages, and variations in product quality. They perform routine maintenance and repairs to keep the equipment in good working condition.

- Troubleshoots equipment malfunctions, identifying and resolving issues promptly.

- Performs basic maintenance and repairs, such as cleaning, lubrication, and adjustments.

4. Quality Assurance

Mat Machine Tenders pay attention to the quality and specifications of the finished mats. They conduct visual inspections, check dimensions, and make adjustments to the process or equipment as needed to ensure the products meet the desired standards.

- Conducts in-process and final quality checks on the mats.

- Identifies and corrects defects or inconsistencies.

Interview Tips

Preparing for a Mat Machine Tender interview requires adequate research, practice, and confidence. Here are some valuable tips to help candidates ace the interview:

1. Research the Role and Company

Candidates should thoroughly research the Mat Machine Tender role and the specific responsibilities expected at the company they are applying for. This knowledge will help them understand the requirements and expectations of the position.

- Read the job description thoroughly and identify key responsibilities and qualifications.

- Visit the company’s website to learn about their business, values, and recent developments.

2. Highlight Relevant Skills and Experience

Candidates should emphasize their skills and experience that align with the job requirements. They should provide specific examples and quantify their accomplishments whenever possible.

- Showcase expertise in operating and monitoring automated machinery in a manufacturing environment.

- Emphasize experience in handling and processing various types of materials.

3. Prepare for Technical Questions

Interviewers may ask technical questions to assess a candidate’s knowledge of mat-making processes and equipment. Candidates should prepare for questions about:

- Different types of mat-making machines and their functions.

- Material properties, handling, and storage methods.

4. Practice Common Interview Questions

Candidates should anticipate and practice answering common interview questions such as:

- Tell me about yourself and your experience in manufacturing.

- Why are you interested in this Mat Machine Tender role?

- How do you handle troubleshooting and resolving equipment issues?

Next Step:

Now that you’re armed with the knowledge of Mat Machine Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mat Machine Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini