Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Material Man position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

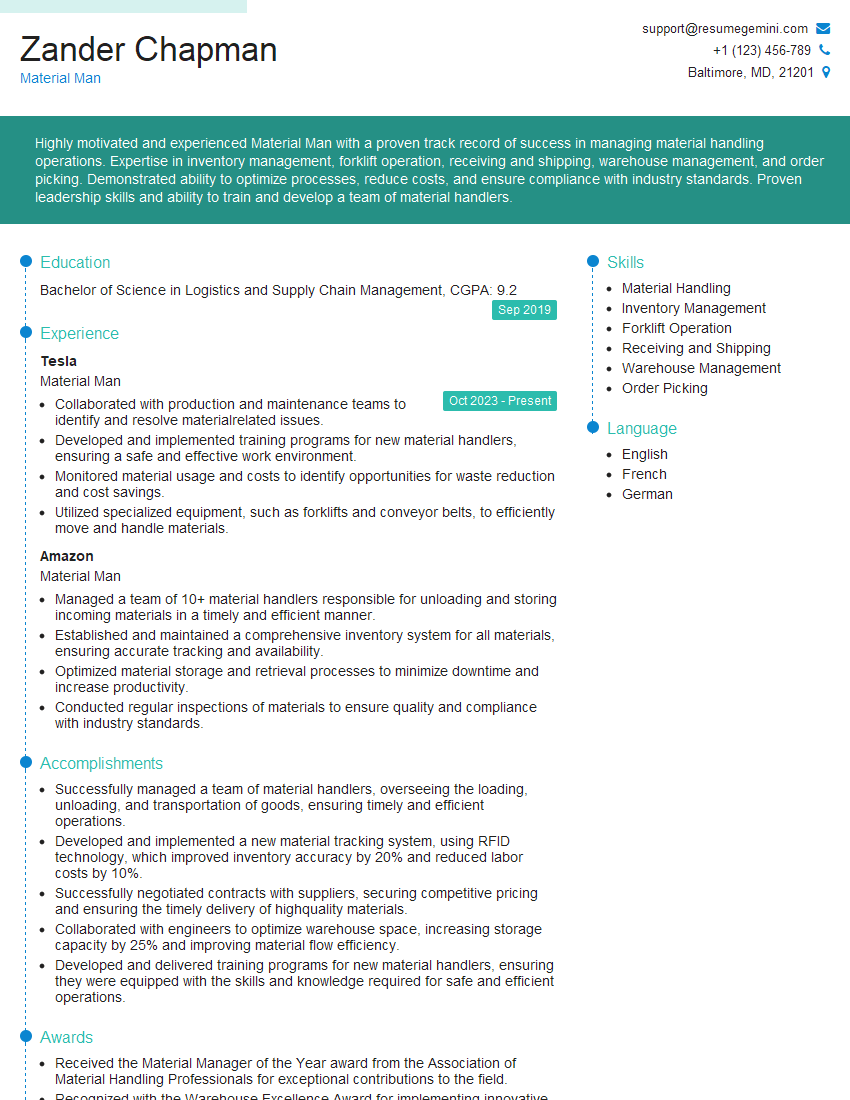

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Material Man

1. Explain the process of determining the compressive strength of concrete?

The compressive strength of concrete is determined by carrying out a compression test, which involves subjecting a cylindrical or cube-shaped concrete specimen to a compressive load until it fails. The maximum load sustained by the specimen before failure is recorded and divided by the cross-sectional area of the specimen to obtain the compressive strength.

2. What are the different types of cement that are used in concrete?

Portland Cement

- Most common type of cement

- Made from limestone, clay, and other materials

- Used in a wide variety of concrete applications

Blended Cement

- Contains a mixture of portland cement and other materials, such as fly ash or slag

- Offers improved performance in certain applications, such as resistance to sulfate attack or high temperatures

3. What are the factors that affect the setting time of concrete?

- Type of cement

- Water-to-cement ratio

- Temperature

- Additives

4. How do you design a concrete mix?

The design of a concrete mix involves determining the appropriate proportions of cement, aggregates, water, and any admixtures to achieve the desired properties for the specific application. This can be done using various methods, such as the ACI method or the British Standard method.

5. What are the different types of aggregates that are used in concrete?

Coarse Aggregates

- Gravel

- Crushed stone

- Provide strength and reduce shrinkage

Fine Aggregates

- Sand

- Fill voids between coarse aggregates

- Improve workability

6. What are the different types of admixtures that are used in concrete?

Chemical Admixtures

- Accelerators

- Retarders

- Water reducers

- Air-entraining agents

Mineral Admixtures

- Fly ash

- Slag

- Silica fume

7. What are the different types of concrete finishes that are available?

Troweled Finishes

- Smooth surface

- Used for interiors and exteriors

Exposed Aggregate Finishes

- Rough surface with exposed aggregates

- Used for decorative purposes

Stamped Concrete Finishes

- Imprinted with patterns or designs

- Used for patios, walkways, and other decorative applications

8. What are the different types of concrete curing methods?

Water Curing

- Most common method

- Concrete is kept moist by spraying or ponding water

Membrane Curing

- A membrane is applied to the surface of the concrete to prevent moisture loss

- Can be used in hot or windy conditions

9. What are the different types of concrete testing methods?

Compressive Strength Test

- Measures the compressive strength of concrete

- Used to evaluate the quality of concrete

Flexural Strength Test

- Measures the flexural strength of concrete

- Used to evaluate the concrete’s resistance to bending

Splitting Tensile Strength Test

- Measures the splitting tensile strength of concrete

- Used to evaluate the concrete’s resistance to cracking

10. What are the different types of concrete repair methods?

Patching

- Used to repair small areas of damaged concrete

- Involves removing the damaged concrete and replacing it with new concrete

Overlay

- Used to repair larger areas of damaged concrete

- Involves placing a new layer of concrete over the existing concrete

Jacketing

- Used to repair severely damaged concrete

- Involves encasing the damaged concrete in a new layer of concrete

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Material Man.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Material Man‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Material Man is responsible for managing the procurement, storage, and distribution of materials for construction projects. They work closely with project managers, contractors, and suppliers to ensure that materials are delivered on time and within budget. The key job responsibilities of a Material Man include:

1. Procurement

The Material Man is responsible for identifying and procuring the necessary materials for a project. This includes researching suppliers, requesting quotes, and negotiating prices. They must also ensure that the materials meet the project’s specifications and are available when needed.

2. Storage

The Material Man is responsible for storing and managing materials until they are needed on-site. This includes creating and maintaining inventory, managing storage space, and ensuring that materials are protected from damage and theft.

3. Distribution

The Material Man is responsible for distributing materials to the project site. This includes scheduling deliveries, coordinating with contractors, and ensuring that materials are delivered to the correct location and on time.

4. Inventory Management

The Material Man is responsible for maintaining an accurate inventory of all materials. This includes tracking materials as they are received, stored, and distributed. They must also identify and report any shortages or surpluses.

5. Cost Control

The Material Man is responsible for managing the costs associated with materials. This includes negotiating prices with suppliers, optimizing storage and distribution costs, and identifying cost-saving opportunities.

Interview Tips

Preparing for an interview for a Material Man position can be daunting, but following these tips can help you succeed:

1. Research the Company and the Role

Before the interview, take the time to research the company and the specific role you are applying for. This will help you understand the company’s culture, values, and goals, as well as the key responsibilities of the Material Man position. You should also be prepared to discuss your own qualifications and experience in relation to the job requirements.

- Read the company’s website and social media pages.

- Review the job description and identify the key skills and experience required.

- Network with people who work or have worked for the company.

2. Prepare for Common Interview Questions

There are several common interview questions that you can expect to be asked in an interview for a Material Man position. These questions may include:

- Tell me about your experience in procurement, storage, and distribution of materials.

- How do you manage inventory and control costs?

- What is your experience with negotiating with suppliers?

- What are your strengths and weaknesses as a Material Man?

You can prepare for these questions by brainstorming answers that highlight your skills and experience. You should also be prepared to provide specific examples of your work.

3. Practice Your Answers

Once you have prepared for the common interview questions, practice your answers out loud. This will help you become more comfortable and confident in your delivery. You can practice with a friend, family member, or career counselor.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are taking the interview seriously.

5. Be Yourself and Be Enthusiastic

The most important thing is to be yourself and be enthusiastic about the job. The interviewer wants to know who you are and what you can bring to the company. Be honest, open, and share your passion for the field of materials management.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Material Man, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Material Man positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.