Feeling lost in a sea of interview questions? Landed that dream interview for Material Requisitioner but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Material Requisitioner interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

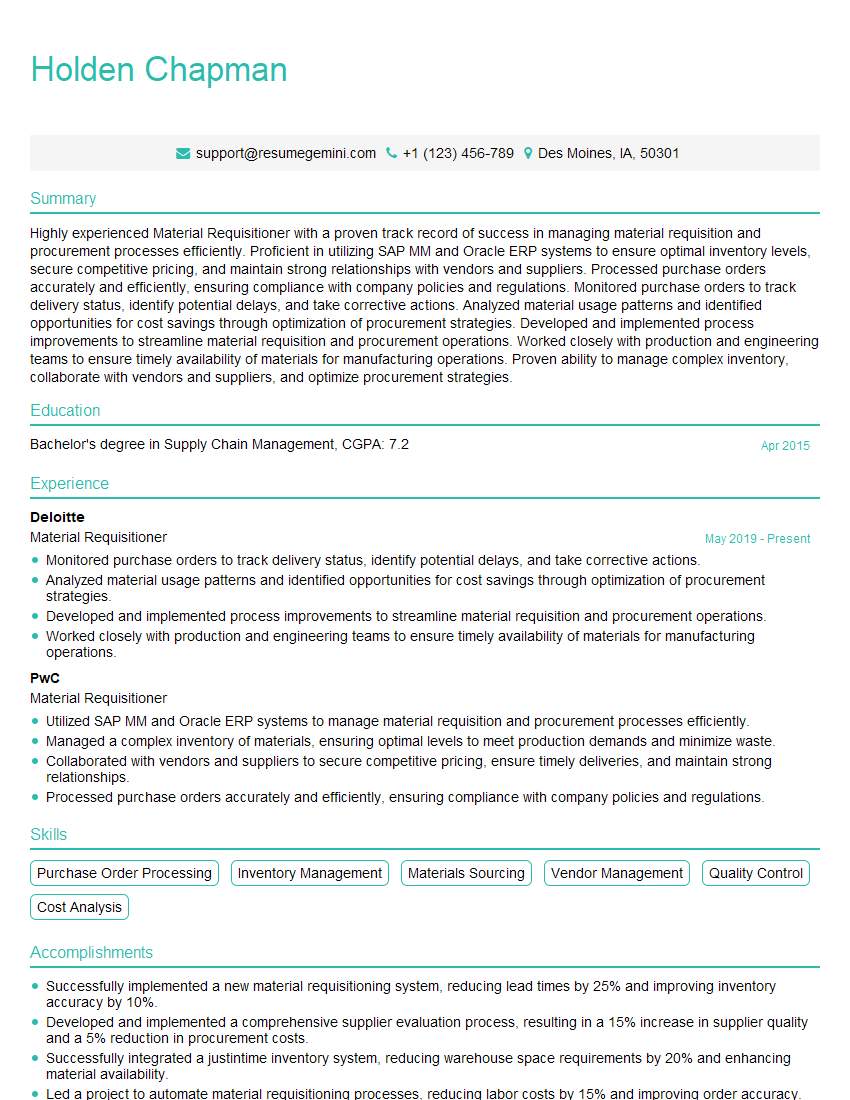

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Material Requisitioner

1. What are the key responsibilities of a Material Requisitioner?

As a Material Requisitioner, I would be responsible for the following key tasks:

- Creating and processing material requisitions in a timely and accurate manner, ensuring that all required materials are available for production and other operations

- Maintaining inventory levels by monitoring stock levels and placing replenishment orders as needed

- Verifying purchase orders and invoices to ensure that they are accurate and complete

- Coordinating with suppliers to ensure timely delivery of materials and resolving any issues that may arise

- Working with internal stakeholders, such as production and engineering teams, to identify and procure the necessary materials for their projects

- Staying up-to-date on industry best practices and regulations related to material requisitioning

2. Describe the process you would follow to create and process a material requisition.

Pre-requisitioning Activities

- Identify the need for materials, either through direct requests from internal stakeholders or by reviewing inventory levels and identifying potential shortages.

- Gather all necessary information, such as the type of material, quantity required, delivery date, and supplier details.

Creating the Material Requisition

- Enter the required information into the material requisition system, including the item description, quantity, unit of measure, and any special instructions.

- Obtain necessary approvals from authorized personnel, such as managers or supervisors.

Processing the Material Requisition

- Review the requisition for accuracy and completeness, ensuring that all required fields are filled out and that the information is correct.

- Send the requisition to the designated supplier or purchasing department for processing.

- Track the status of the requisition throughout the procurement process, ensuring timely delivery of materials.

3. How do you maintain inventory levels and ensure that there are no stockouts or overstocking of materials?

To maintain inventory levels and prevent stockouts or overstocking, I would follow these steps:

- Establish minimum and maximum inventory levels for each item, based on historical usage, lead times, and safety stock requirements.

- Monitor inventory levels regularly, using inventory management systems or manual tracking methods.

- Create reorder points based on minimum inventory levels and lead times to ensure timely replenishment of stocks.

- Place replenishment orders when inventory levels fall below reorder points.

- Coordinate with suppliers to ensure timely delivery of materials and adjust orders as needed based on changes in demand or supply.

- Work with internal stakeholders to optimize inventory levels, reduce waste, and improve overall inventory management efficiency.

4. How do you handle discrepancies or issues that may arise during the material requisitioning process?

When faced with discrepancies or issues during the material requisitioning process, I would take the following steps:

- Identify the root cause of the discrepancy or issue, whether it’s an error in the requisition, supplier delivery delays, or quality problems.

- Communicate the issue promptly to all relevant parties, including the supplier, internal stakeholders, and management.

- Work with the supplier to resolve the issue, negotiate alternative delivery arrangements, or find a replacement material if necessary.

- Document all communication and actions taken to resolve the issue and prevent similar issues in the future.

- Escalate the issue to management if it cannot be resolved at my level and requires higher-level intervention.

5. How do you stay up-to-date on industry best practices and regulations related to material requisitioning?

To stay up-to-date on industry best practices and regulations related to material requisitioning, I would:

- Attend industry conferences, workshops, and training programs.

- Read trade publications and industry journals.

- Network with other material requisitioners and procurement professionals.

- Participate in online forums and discussion groups.

- Review and comply with relevant industry standards and regulations, such as ISO 9001 and ISO 14001.

6. What are some of the challenges you have faced as a Material Requisitioner and how did you overcome them?

One of the challenges I faced as a Material Requisitioner was dealing with supplier delivery delays. To overcome this, I implemented a proactive approach by:

- Establishing strong relationships with suppliers and regularly monitoring their performance.

- Diversifying the supplier base to reduce reliance on a single source.

- Negotiating backup delivery arrangements with alternative suppliers.

- Working closely with the production team to adjust production schedules as needed based on material availability.

7. What are some of the key qualities and skills that make a successful Material Requisitioner?

In my opinion, some of the key qualities and skills that make a successful Material Requisitioner include:

- Strong analytical and problem-solving abilities.

- Excellent communication and interpersonal skills.

- Attention to detail and accuracy.

- Knowledge of inventory management principles.

- Understanding of procurement processes.

- Ability to work independently and as part of a team.

8. How do you prioritize and manage multiple material requisitions simultaneously?

To prioritize and manage multiple material requisitions simultaneously, I would:

- Establish clear priorities based on factors such as lead times, criticality of the materials, and impact on production schedules.

- Use a task management system to track the status of each requisition and identify potential bottlenecks.

- Communicate regularly with stakeholders to keep them informed of progress and any anticipated delays.

- Delegate tasks to team members as needed to ensure timely processing of requisitions.

- Continuously monitor and adjust priorities as circumstances change.

9. What strategies do you use to reduce material costs and improve cost efficiency?

Some of the strategies I would use to reduce material costs and improve cost efficiency include:

- Conducting thorough market research to identify the most competitive suppliers.

- Negotiating favorable pricing and terms with suppliers.

- Exploring volume discounts and bulk purchasing options.

- Evaluating alternative materials and suppliers to find cost-effective solutions.

- Implementing inventory optimization techniques to reduce waste and overstocking.

10. How do you ensure the accuracy and completeness of material requisitions?

To ensure the accuracy and completeness of material requisitions, I would:

- Establish clear guidelines and procedures for creating and submitting requisitions.

- Provide training to employees on the requisitioning process and best practices.

- Implement a review and approval process to verify the accuracy and completeness of requisitions before they are submitted to suppliers.

- Regularly audit material requisitions to identify and correct any errors or discrepancies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Material Requisitioner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Material Requisitioner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Material Requisitioners are responsible for managing the procurement and distribution of materials within an organization. They work closely with other departments to identify and fulfill material needs, ensuring that the organization has the necessary resources to operate efficiently.

1. Material Planning and Forecasting

Material Requisitioners analyze historical data, current inventory levels, and future production plans to forecast material needs. They work with suppliers to secure materials at the best possible price and ensure that materials are delivered on time.

- Analyze historical data and current inventory levels to identify trends and forecast future material needs.

- Develop and implement material planning strategies to ensure that the organization has the necessary materials to meet production demands.

2. Material Procurement

Material Requisitioners are responsible for issuing purchase orders, negotiating with suppliers, and managing vendor relationships. They work to ensure that materials are procured in a timely, cost-effective, and ethical manner.

- Issue purchase orders to suppliers based on material requirements.

- Negotiate with suppliers to secure the best possible price and delivery terms.

- Manage vendor relationships and ensure that suppliers meet quality and delivery standards.

3. Material Inventory Management

Material Requisitioners maintain inventory levels to ensure that the organization has the necessary materials on hand. They work with other departments to track inventory, identify excess materials, and optimize inventory levels.

- Maintain inventory levels and track material usage.

- Identify excess materials and implement strategies to reduce inventory levels.

- Optimize inventory levels to minimize storage costs and ensure that materials are available when needed.

4. Material Distribution

Material Requisitioners are responsible for distributing materials to production and other departments within the organization. They work to ensure that materials are delivered on time and in the correct quantities.

- Distribute materials to production and other departments.

- Ensure that materials are delivered on time and in the correct quantities.

- Monitor material usage and identify areas for improvement.

Interview Tips

Preparing thoroughly for a Material Requisitioner interview is crucial to making a positive impression and increasing your chances of success. Here are some tips to help you prepare:

1. Research the company and the role

Take the time to research the company you are interviewing with and the specific role you are applying for. This will give you a good understanding of the company’s culture, values, and the specific skills and experience required for the job.

- Visit the company website to learn about their history, mission, and products or services.

- Read industry news and articles to stay up-to-date on current trends and best practices.

- Connect with people in your network who work in similar roles to gain insights into the company and the industry.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this role?”. Prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral questions (Situation, Task, Action, Result).

- Focus on highlighting your skills, experience, and accomplishments that are most relevant to the job.

- Quantify your results whenever possible to demonstrate the impact of your work.

3. Be prepared to ask questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the role. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s culture and values.

- Inquire about the specific responsibilities and expectations of the role.

- Ask about opportunities for growth and advancement within the company.

4. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the opportunity.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Plan your route in advance and give yourself plenty of time to get to the interview location.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Material Requisitioner interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.