Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Materials and Processes Manager position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

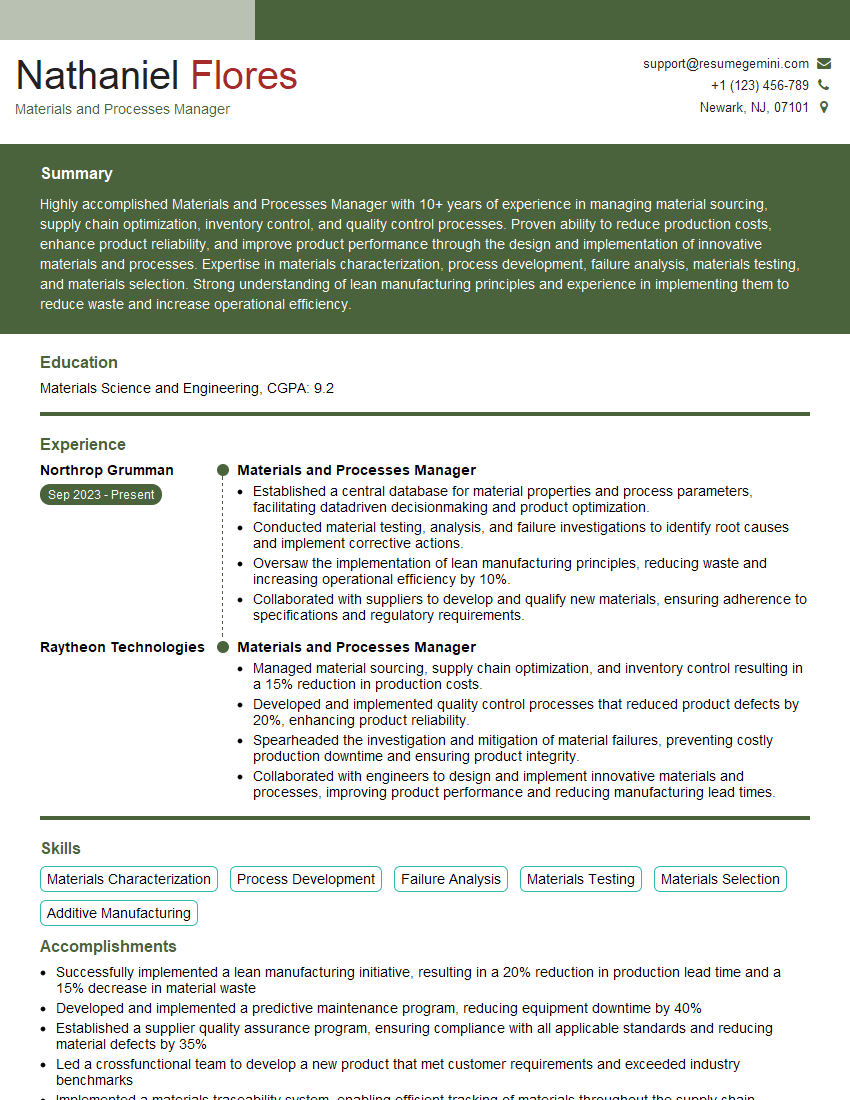

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Materials and Processes Manager

1. How do you evaluate the properties of materials?

- Tensile testing to determine yield strength and ultimate tensile strength

- Compression testing to measure yield strength and ultimate compressive strength

- Fatigue testing to assess material resistance to cyclic loading

- Impact testing to determine material toughness and resilience

- Hardness testing to measure material resistance to indentation or scratching

2. What are the key factors to consider when selecting materials for a specific application?

Mechanical properties

- Strength

- Stiffness

- Toughness

Physical properties

- Density

- Thermal conductivity

- Electrical conductivity

Chemical properties

- Corrosion resistance

- Oxidation resistance

- Biocompatibility

3. How do you manage the quality of materials and processes within a manufacturing environment?

- Implementing and maintaining a quality management system

- Conducting regular inspections and testing of materials and products

- Analyzing data to identify trends and areas for improvement

- Collaborating with vendors to ensure the quality of incoming materials

- Training employees on quality control procedures

4. What are the latest trends in materials engineering?

- Advanced materials with enhanced properties

- Biomaterials for medical applications

- Sustainable materials with low environmental impact

- Data-driven materials development

- Additive manufacturing for complex geometries

5. How do you stay updated with the latest advancements in materials science?

- Attending conferences and seminars

- Reading industry journals and publications

- Participating in professional organizations

- Collaborating with researchers and academia

- Continuing education and training

6. What is the role of materials engineering in product development?

- Developing new materials with improved properties for specific applications

- Selecting appropriate materials based on performance requirements

- Optimizing material processing to enhance product quality and functionality

- Collaborating with design and manufacturing teams to ensure optimal material integration

- Testing and evaluating materials and products to ensure compliance with specifications

7. How do you handle situations where material properties do not meet design specifications?

- Investigate the cause of the discrepancy

- Identify alternative materials that meet the required specifications

- Work with suppliers to improve the quality of incoming materials

- Modify the design or manufacturing process to accommodate the material properties

- Recommend additional testing or analysis to confirm material performance

8. What are the challenges you have faced in your previous role as a Materials and Processes Manager?

- Implementing a new quality control system

- Managing a team of materials engineers

- Developing innovative materials for a cutting-edge technology

- Navigating regulatory compliance requirements

- Overcoming material performance issues in a high-volume production environment

9. What are your strengths and weaknesses as a Materials and Processes Manager?

Strengths

- Strong technical knowledge of materials and processes

- Excellent problem-solving and analytical skills

- Proven leadership and team management capabilities

- Expertise in quality control and regulatory compliance

- Passion for materials engineering and innovation

Weaknesses

- Limited experience in additive manufacturing technologies

- Some knowledge gaps in biomaterials and sustainable materials

- Occasional difficulty delegating tasks

- Tendency to be overly detail-oriented at times

- Need for further development in stakeholder management

10. What are your salary expectations?

My salary expectations are commensurate with my qualifications and experience in materials engineering and management. According to industry benchmarks and market research, the average salary range for a Materials and Processes Manager with my skillset is between $120,000 and $150,000 per year.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Materials and Processes Manager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Materials and Processes Manager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Materials and Processes Manager is responsible for overseeing the development, implementation, and maintenance of materials and processes used in the manufacturing of products.

1. Materials Management

Manages all aspects of materials management, including sourcing, procurement, storage, and distribution.

- Develops and executes strategies for optimizing materials procurement and inventory management.

- Negotiates contracts with suppliers and maintains relationships with key vendors.

2. Process Development and Improvement

Develops and implements new processes and technologies to improve manufacturing efficiency and product quality.

- Conducts research on new materials and technologies to identify potential applications.

- Collaborates with engineering and production teams to optimize processes and reduce waste.

3. Quality Assurance

Establishes and maintains quality control standards for materials and processes.

- Conducts regular inspections and audits to ensure compliance with quality standards.

- Investigates and resolves quality issues in a timely and efficient manner.

4. Cost Control

Controls costs associated with materials and processes, including procurement, inventory, and production.

- Analyzes costs and identifies areas for improvement.

- Implements cost-saving measures without compromising product quality.

Interview Tips

To ace an interview for a Materials and Processes Manager position, it is important to prepare thoroughly and showcase your skills and experience related to the key job responsibilities.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for.

- Review the company’s website, LinkedIn page, and other online resources to understand their business, products, and culture.

- Read the job description carefully and identify the key skills and experience required.

2. Highlight Your Industry Knowledge and Experience

During the interview, emphasize your knowledge of the materials and processes industry.

- Discuss your experience in materials sourcing, process development, quality assurance, and cost control.

- Provide specific examples of projects where you made significant contributions.

3. Demonstrate Your Analytical and Problem-Solving Skills

Materials and Processes Managers must be able to analyze data, identify problems, and develop solutions.

- Share examples of how you have used data analysis to improve materials management or process efficiency.

- Discuss how you have successfully resolved complex technical issues.

4. Emphasize Your Communication and Interpersonal Skills

Effective communication and interpersonal skills are essential for a Materials and Processes Manager.

- Explain how you have successfully collaborated with cross-functional teams, including engineering, production, and supply chain.

- Describe your experience in presenting technical information to senior management and external stakeholders.

5. Be Enthusiastic and Passionate

The best Materials and Processes Managers are passionate about their work and eager to make a difference.

- Express your enthusiasm for the field and your commitment to driving innovation and improving manufacturing processes.

- Share your vision for how you can contribute to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Materials and Processes Manager interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.