Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Materials Coordinator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

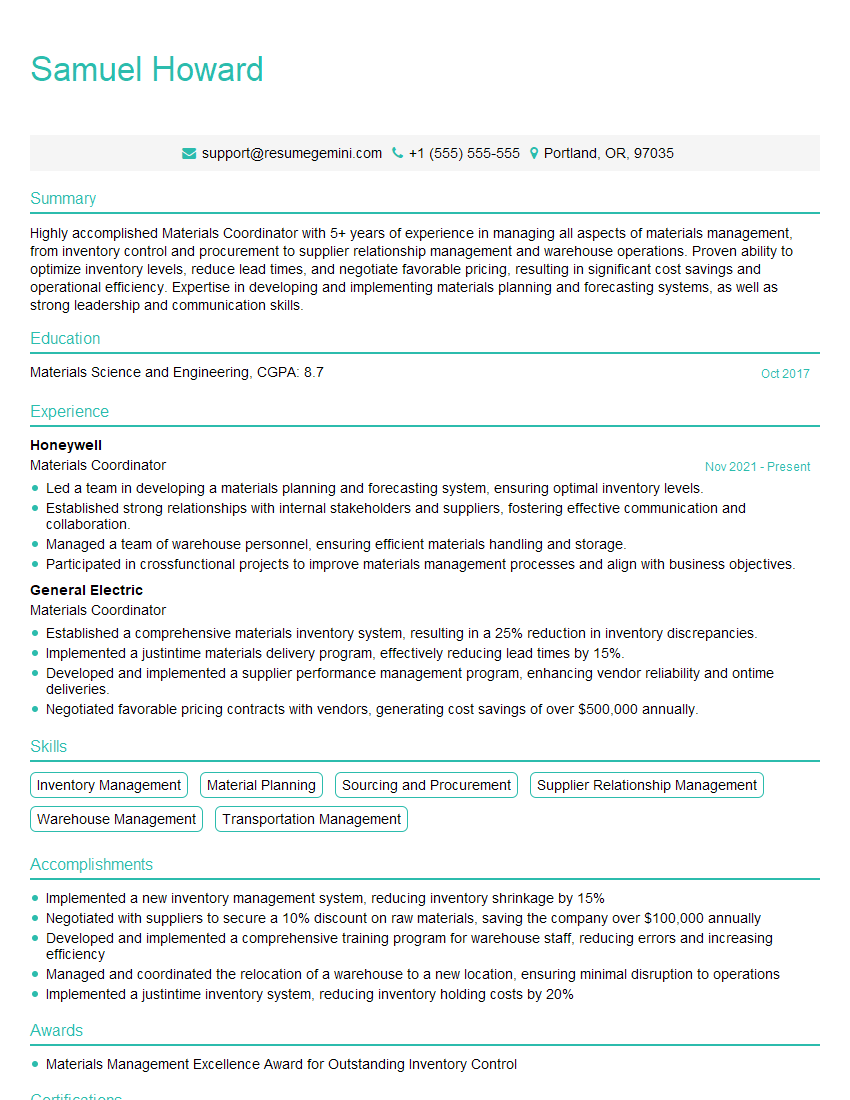

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Materials Coordinator

1. Tell me about your experience in managing inventory levels and ensuring the availability of materials for production?

In my previous role as Materials Coordinator at XYZ Manufacturing, I was responsible for developing and implementing inventory management strategies to optimize material availability and minimize stockouts. I utilized inventory control systems to monitor stock levels, forecast demand, and generate replenishment orders. Through proactive planning and coordination with suppliers, I ensured timely deliveries and maintained optimal inventory levels to meet production requirements.

2. Describe the methodologies you have used for material sourcing and how you have evaluated and selected suppliers?

Supplier Evaluation and Selection

- Established supplier evaluation criteria based on quality, price, delivery time, and financial stability

- Conducted thorough due diligence on potential suppliers, including site visits and reference checks

- Negotiated contracts that clearly outlined specifications, pricing, delivery terms, and performance metrics

Material Sourcing

- Identified potential material sources through industry research and networking

- Evaluated materials based on specifications, cost, availability, and lead time

- Developed and maintained supplier relationships to ensure reliable and cost-effective material sourcing

3. How have you handled discrepancies or shortages in material deliveries and what steps have you taken to resolve them?

When faced with material discrepancies or shortages, I promptly notify the supplier and investigate the root cause. I work closely with the supplier to determine the extent of the issue and develop a plan to resolve it. If necessary, I identify alternative suppliers or expedite shipments to minimize production delays. I document all interactions and resolutions to prevent similar issues in the future.

4. Explain how you have utilized technology or software to improve the efficiency of the materials management process?

I am proficient in using enterprise resource planning (ERP) systems and inventory management software. I have implemented automated inventory tracking and replenishment processes to streamline operations. I also leverage data analytics to identify trends, optimize ordering patterns, and improve forecast accuracy. Additionally, I explore and adopt emerging technologies, such as RFID or IoT sensors, to enhance inventory visibility and traceability.

5. Describe your understanding of material quality control and the measures you have taken to ensure the quality of incoming materials?

Material quality is crucial for production efficiency and customer satisfaction. I have implemented a comprehensive quality control process by establishing clear acceptance criteria and inspection procedures. I work closely with suppliers to define quality standards, conduct supplier audits, and ensure that materials meet specifications. Upon receipt, I conduct thorough inspections, utilizing testing equipment and quality control techniques to verify material quality and conformance to standards.

6. How have you managed relationships with suppliers and how have you fostered effective communication and collaboration?

Building strong relationships with suppliers is essential for successful materials management. I establish open and transparent communication channels with suppliers and work closely with them to understand their capabilities and lead times. I regularly schedule meetings, conduct site visits, and participate in industry events to foster collaboration. By maintaining regular contact, I am better able to anticipate potential issues, negotiate favorable terms, and ensure timely material delivery.

7. Describe your approach to materials planning and forecasting and how you have aligned material availability with production schedules?

Accurate materials planning and forecasting are crucial to avoid disruptions and optimize production. I utilize historical data, demand projections, and production schedules to develop detailed material plans. I work closely with production teams to understand their requirements and ensure that materials are available on time and in the right quantities. I also monitor industry trends and adjust forecasts as needed to mitigate supply chain risks and maintain optimal inventory levels.

8. How have you handled material cost optimization and what techniques have you employed to reduce procurement expenses?

Material cost optimization is essential for profitability. I conduct thorough market research to identify cost-effective suppliers and negotiate favorable pricing. I explore alternative materials and suppliers without compromising quality. I also implement value analysis and standardization to reduce material waste and optimize purchasing strategies. Additionally, I leverage vendor discounts and early payment programs to further reduce procurement costs.

9. Describe your experience in managing hazardous or regulated materials and how you have ensured compliance with environmental and safety regulations?

Handling hazardous or regulated materials requires specialized knowledge and adherence to strict regulations. I have received training on hazardous materials management and am familiar with relevant regulations and industry best practices. I ensure proper storage, labeling, and disposal of hazardous materials. I conduct regular inspections and audits to verify compliance and minimize risks. I also collaborate with environmental health and safety teams to ensure that all materials are handled, stored, and disposed of in a safe and environmentally responsible manner.

10. How have you stayed up-to-date with the latest materials management trends and technologies?

The materials management landscape is constantly evolving. I actively participate in industry events, conferences, and webinars to stay abreast of the latest trends and technologies. I subscribe to trade publications and follow industry thought leaders to expand my knowledge. I also seek opportunities for professional development, such as certifications or online courses, to enhance my skills and stay ahead of the curve.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Materials Coordinator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Materials Coordinator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Materials Coordinators play a vital role in managing the flow of materials within an organization, ensuring that the right materials are available in the right place and at the right time. Their responsibilities are diverse and can vary depending on the industry and size of the organization.

1. Material Procurement and Inventory Management

Coordinating with suppliers to procure materials and ensure timely delivery.

- Maintaining inventory levels, conducting audits, and implementing inventory control measures.

- Monitoring material costs and identifying opportunities for cost optimization.

2. Material Logistics and Warehousing

Coordinating the transportation and storage of materials.

- Ensuring materials are stored safely and securely, following appropriate handling and storage procedures.

- Managing warehouse operations, including receiving, putaway, and shipping.

3. Material Planning and Forecasting

Forecasting future material requirements based on production schedules, sales forecasts, and historical data.

- Developing and implementing production schedules to optimize material usage and minimize waste.

- Collaborating with other departments, such as production, engineering, and purchasing, to ensure alignment of material requirements.

4. Quality Assurance and Compliance

Ensuring the quality of incoming materials meets specifications.

- Conducting quality checks and inspections, and coordinating with suppliers to resolve quality issues.

- Adhering to regulatory and industry standards related to material management.

Interview Tips

Preparing for an interview for a Materials Coordinator position requires a thorough understanding of the role and the organization. Here are some tips to help you ace the interview:

1. Research the Company and the Role

Familiarize yourself with the company’s industry, products/services, and recent developments.

- Review the job description thoroughly and identify the key responsibilities and qualifications.

- Prepare specific examples from your previous experience that align with the job requirements.

2. Highlight Your Skills and Experience

Quantify your accomplishments and use specific metrics to demonstrate your impact.

- Emphasize your expertise in material procurement, inventory management, logistics, and quality control.

- Discuss your experience in implementing and managing inventory systems, such as ERP or MRP.

3. Demonstrate Your Problem-Solving and Communication Skills

Materials Coordinators often face challenges and must find solutions quickly and effectively.

- Provide examples of how you have resolved supply chain disruptions, optimized inventory levels, or improved material handling processes.

- Highlight your ability to communicate effectively with suppliers, production teams, and other stakeholders.

4. Be Prepared for Industry-Specific Questions

Research the specific industry and the materials commonly used in that sector.

- Be familiar with industry best practices and regulatory requirements related to material management.

- Discuss how your knowledge and experience align with the industry’s specific needs.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Materials Coordinator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.