Feeling lost in a sea of interview questions? Landed that dream interview for Materials Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Materials Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

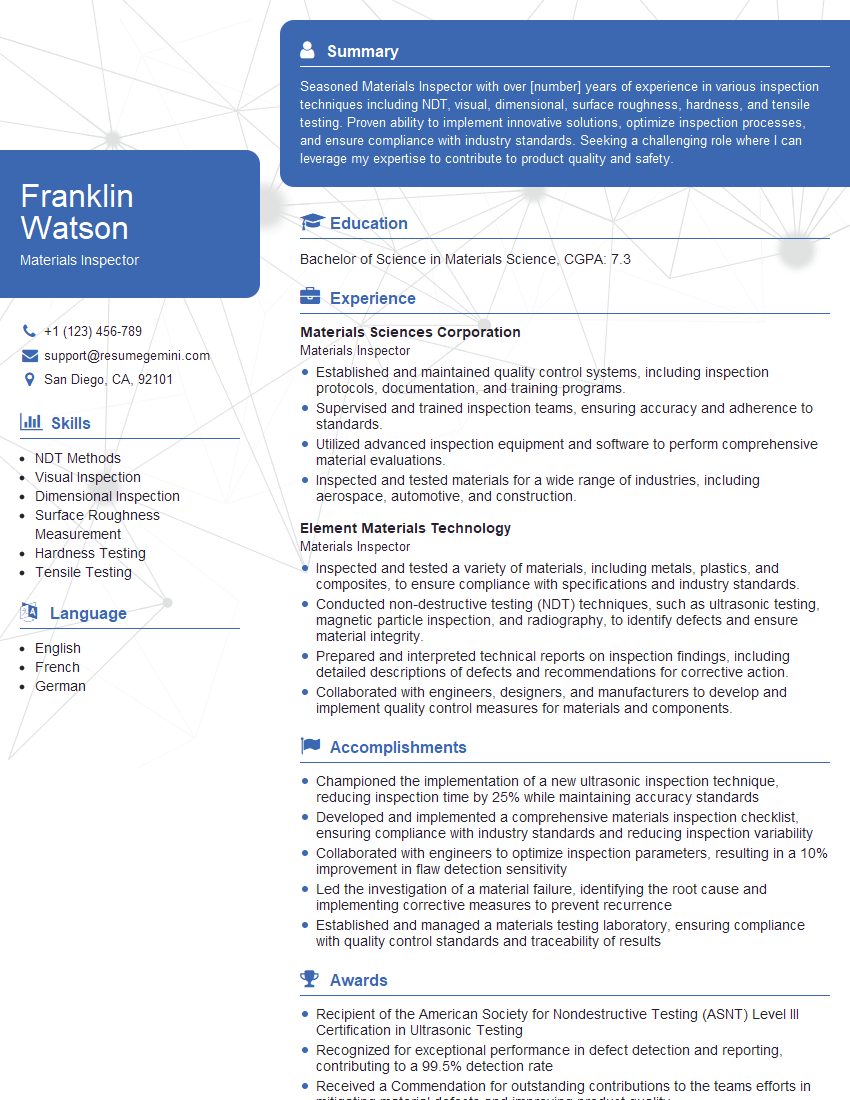

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Materials Inspector

1. How do you develop an inspection plan for a new material?

I start by understanding the project requirements, specifications, and codes that apply to the material. This helps me determine the critical properties and characteristics that need to be inspected.

Next, I conduct a risk assessment to identify potential failure modes and their consequences. This allows me to prioritize the inspections that are most important for ensuring the safety and reliability of the material.

Based on my risk assessment and project requirements, I develop a comprehensive inspection plan that outlines the specific tests, measurements, and procedures to be performed, as well as the acceptance criteria for each.

2. What are the different types of non-destructive testing (NDT) methods, and when should each be used?

Surface Inspection Methods

- Visual Inspection: A simple and cost-effective method for detecting surface defects such as cracks, scratches, and corrosion.

- Liquid Penetrant Inspection (PT): Used to detect surface-breaking cracks and other discontinuities by applying a colored dye that penetrates the defects.

- Magnetic Particle Inspection (MT): Employs magnetic particles to detect surface and near-surface cracks in ferromagnetic materials.

Subsurface Inspection Methods

- Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal defects such as cracks, voids, and delaminations.

- Radiographic Testing (RT): Employs X-rays or gamma rays to produce an image of the internal structure of the material, revealing defects such as cracks, inclusions, and porosity.

3. What are the key requirements for certifying a material inspector?

Typically, the requirements for certifying a material inspector include:

- Education: Holding a degree in a relevant field, such as materials science, engineering, or quality control.

- Experience: Having a minimum number of years of experience in materials inspection and testing.

- Training: Completing specific training programs and passing certification exams.

- Continuing education: Staying up-to-date on industry standards and best practices through ongoing training and professional development.

4. What are the ethical responsibilities of a material inspector?

- Maintain confidentiality: Keep all sensitive information, such as test results and inspection findings, strictly confidential.

- Report accurately: Provide accurate and unbiased inspection reports, regardless of whether the findings are positive or negative.

- Follow industry standards: Adhere to all applicable industry standards and regulations to ensure the accuracy and reliability of inspections.

- Avoid conflicts of interest: Disclose any potential conflicts of interest and take steps to avoid situations that could compromise their objectivity.

5. What are the latest trends and advancements in materials inspection technology?

- Advanced Nondestructive Testing (NDT) Techniques: Developments in NDT methods, such as phased array ultrasonic testing and time-of-flight diffraction, provide more detailed and accurate inspections.

- Digitalization and Automation: Inspection processes are becoming increasingly automated with the use of digital tools, robotics, and AI-powered systems.

- Sensor Integration: Integration of sensors into materials and structures allows for continuous monitoring and real-time defect detection.

6. How do you ensure the accuracy and reliability of your inspections?

- Calibration and Maintenance: Regularly calibrate and maintain inspection equipment to ensure accurate and consistent measurements.

- Verification and Validation: Conduct periodic verification and validation tests to confirm the accuracy and effectiveness of inspection methods.

- Training and Proficiency: Ensure that all inspectors are adequately trained and proficient in the use of inspection techniques.

7. What software applications do you use for materials inspection?

- Inspection Data Management Software: Manage inspection data, generate reports, and track compliance.

- NDT Image Analysis Software: Analyze and interpret NDT data, such as ultrasonic scans and X-ray images.

- Computer-Aided Inspection (CAI) Software: Automate inspection processes and improve accuracy through image recognition and defect detection algorithms.

8. How do you stay updated on the latest materials and inspection techniques?

- Attend Industry Conferences and Seminars: Participate in industry events to learn about new technologies and best practices.

- Read Technical Publications and Journals: Stay abreast of the latest research and developments in materials inspection.

- Join Professional Organizations: Engage with colleagues and experts in the field to share knowledge and stay informed.

9. Describe a challenging materials inspection project you have worked on.

In a recent project, I was tasked with inspecting a critical component for a high-performance aircraft. The component had complex geometry and was made from a new and highly specialized material. I developed a customized inspection plan that combined advanced NDT techniques, such as phased array ultrasonic testing and fiber optic endoscopy, to ensure the integrity of the component.

Through thorough and meticulous inspections, I identified several critical defects that could have compromised the safety of the aircraft if left undetected. My findings led to the timely repair of the component, preventing a potential catastrophic failure.

10. How do you handle disagreements or conflicting interpretations of inspection results?

When disagreements or conflicting interpretations arise, I approach the situation professionally and objectively. I:

- Review the inspection data and applicable standards thoroughly.

- Consult with colleagues, experts, or the relevant authorities for additional input and perspectives.

- Document my findings and rationale clearly and provide evidence to support my interpretation.

- Engage in respectful dialogue to discuss the differences and explore alternative viewpoints.

My goal is to reach a consensus based on sound technical evidence and to ensure that the final decision is in the best interest of safety and quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Materials Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Materials Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Materials Inspectors play a crucial role in ensuring the quality and safety of materials used in various industries. Their responsibilities encompass a wide range of tasks, including:

1. Material Inspection and Testing

Inspecting incoming raw materials and finished products for compliance with specifications.

- Performing physical, chemical, and mechanical tests on materials to assess their properties and performance.

- Using specialized equipment and techniques to determine the composition, structure, and quality of materials.

2. Documentation and Reporting

Maintaining detailed records of inspection activities, including test results, observations, and recommendations.

- Preparing reports and providing feedback to suppliers, manufacturers, and internal stakeholders.

- Documenting any non-conformances or deviations from specifications.

3. Quality Control and Assurance

Implementing and enforcing quality control procedures to ensure materials meet regulatory standards and customer requirements.

- Developing and reviewing quality control plans.

- Auditing suppliers and production processes to verify compliance.

4. Material Handling and Storage

Ensuring materials are handled and stored according to industry best practices.

- Providing guidance on appropriate storage conditions and practices.

- Monitoring inventory levels and ensuring materials are stored securely.

Interview Tips

To ace an interview for a Materials Inspector position, consider the following tips:

1. Research the Company and Industry

Demonstrate your understanding of the company’s business, its products, and the industry it operates in.

- Visit the company website, read industry publications, and attend industry events.

- This will show the interviewer that you have done your homework and are genuinely interested in the role.

2. Highlight Relevant Skills and Experience

Emphasize your knowledge of materials science, inspection techniques, and quality control principles.

- Provide specific examples of projects where you have successfully inspected and tested materials.

- Quantify your accomplishments whenever possible, using metrics such as reduction in defects or improved product quality.

3. Prepare for Common Interview Questions

Anticipate questions about your technical expertise, problem-solving abilities, and communication skills.

- Practice answering questions such as “Describe your experience with non-destructive testing techniques?” or “How do you handle conflicting test results?”

- Prepare concise and articulate responses that demonstrate your knowledge and confidence.

4. Ask Questions

At the end of the interview, don’t hesitate to ask questions about the role, the team, and the company’s culture.

- This shows that you are interested in the opportunity and keen to learn more.

- Prepare questions that demonstrate your curiosity and desire to contribute to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Materials Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!